Steel structure splicing includes splicing in the workshop and on-site. The splicing methods include welding and bolting. We should implement…

The types of steel building structures are the portal rigid steel frame, the frame structure, the truss structure, and the grid structure. Understanding the advantages and disadvantages of different structural systems is essential to design your project correctly. The forms of stress are also different.

The type of steel building structures:

- The Portal frame structure is a form of a closed structural system. It has a simple force, clear force transmission path, and fast construction speed. Introducing a portal frame structure strengthens the bonding properties of walls and generates more flexible space layouts, thus providing more possibilities for engineering creativity.

- Steel building frame structures are used to construct high-rise and super high-rise buildings, multi-story buildings, and commercial office buildings with the flexibility of their structure. A steel building frame can be adjusted to suit your needs.

- The advantage of Steel Truss Structure is that small cross-section rods can be used to form larger cross-section components, which are often used in industrial and civil buildings such as roofs, bridges, TV towers, mast towers, marine oil production platforms, tower corridors, etc., with large spans or heights In the building.

- The Steel Grid Structure is a high-order, statically indeterminate space structure composed of many rods according to specific rules. The space is small in force, light in weight, rigid, and has good seismic resistance. It can be used as a gymnasium, exhibition hall, rain roof, and canopies and hangars.

1. Portal Frame Steel Building Structures

The portal steel frame comprises hot-rolled or welded section steel, cold-formed C/Z steel, and steel pipe as the main force-bearing components and adopts a light roof and wall structure. The Portal frame is the most common form of the light steel structure.

The rigid portal frame is a structure with rigidly connected beams and columns. It has the characteristics of a simple structure, lightweight, reasonable stress, and simple construction. Therefore, it is widely used in industrial, commercial, agricultural, and Institutional Buildings.

2. Multi-layer Steel Frame Structures

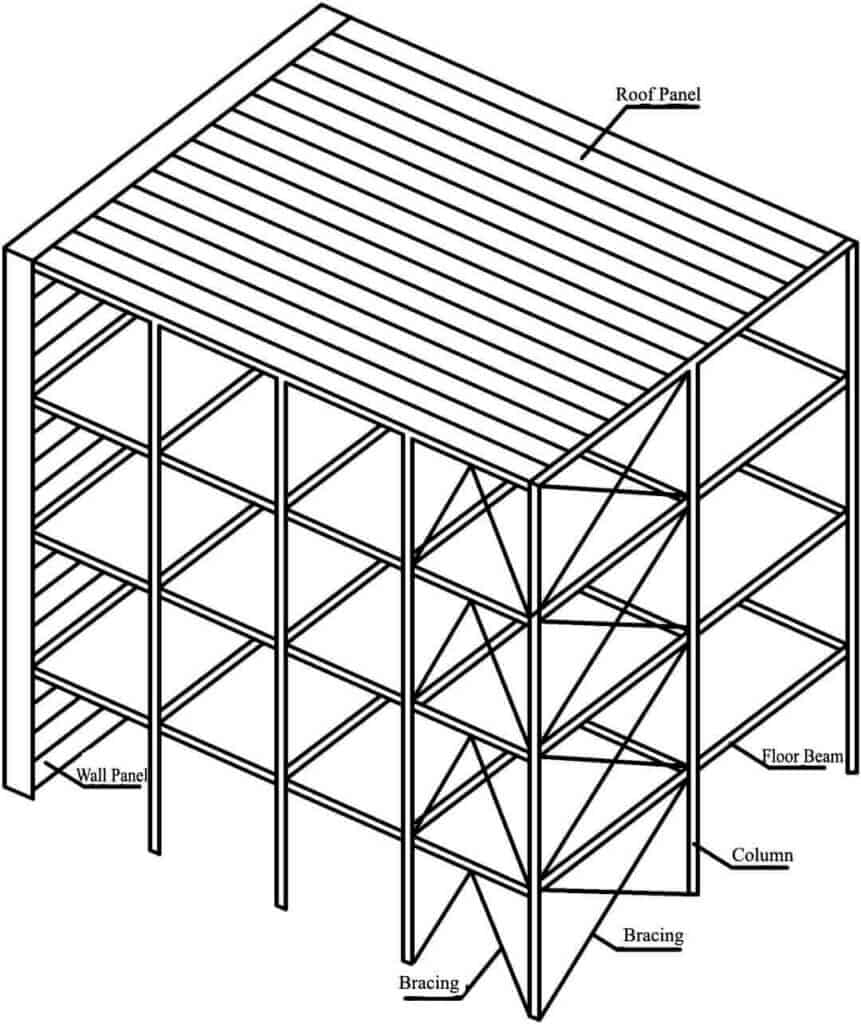

The steel frame structure comprises beams and columns that can withstand vertical and horizontal loads. Columns, beams, bracing, and other members are rigidly or hingedly connected to form a flexible layout and create a larger space. It is widely used in multi-story, high-rise, super-highrise buildings, commercial office buildings, conference centers, etc.

3. Steel Truss Structure

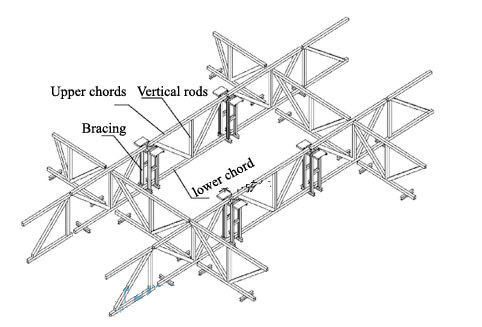

The steel truss structure comprises several rods hinged at both ends of each rod. It can be divided into a plane truss and a space truss. According to the parts section, it can be separated into tube truss and angle steel truss. The truss generally comprises the upper chord, lower chord, vertical rod, diagonal web, and inter-truss support. The steel used in trusses is less than that of solid web beams, the structural weight is lighter, and the rigidity is greater.

The advantage of the steel truss is that it is used to form more significant members with smaller cross-sections. It is often used in roofs, bridges, TV towers, mast towers, marine oil platforms, and tower corridors of industrial and civil buildings.

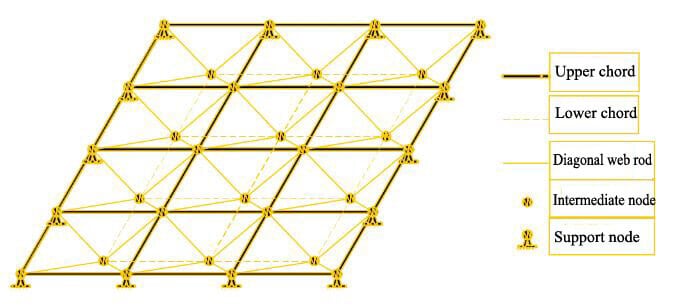

4. Steel Grid Structure

According to a specific rule, the grid structure comprises many rods with minor space stress, are lightweight, have high rigidity, and offer excellent seismic resistance. It is used as a gymnasium, exhibition hall, and aircraft hangar.

5. Cold-formed thin-walled steel building structures

Cold-formed thin-walled steel structures refer to finished steel products with various cross-section shapes bent from steel plates or strips with a thickness of 1.5 to 6 mm in a cold state. Cold-formed steel is an economical cross-section of lightweight, thin-walled steel, known as steel cold-formed or cold-formed profiles.

In industrial, civil, and agricultural buildings, thin-walled steel building structures can make various structures and components, such as roof trusses, rigid frames, grids, purlins, wall beams, and columns.

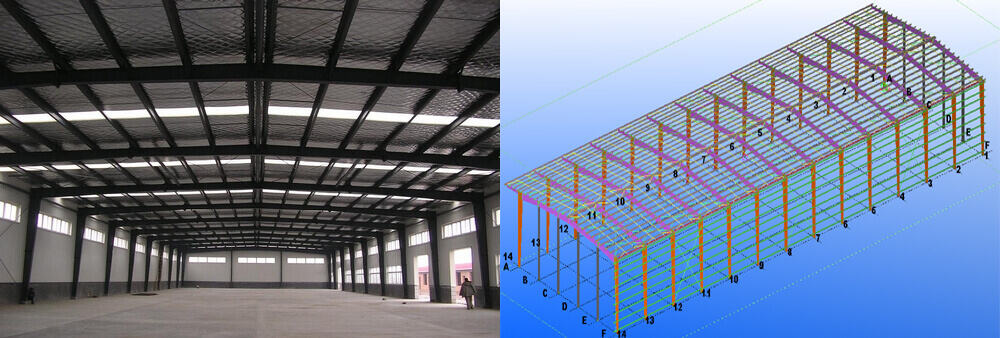

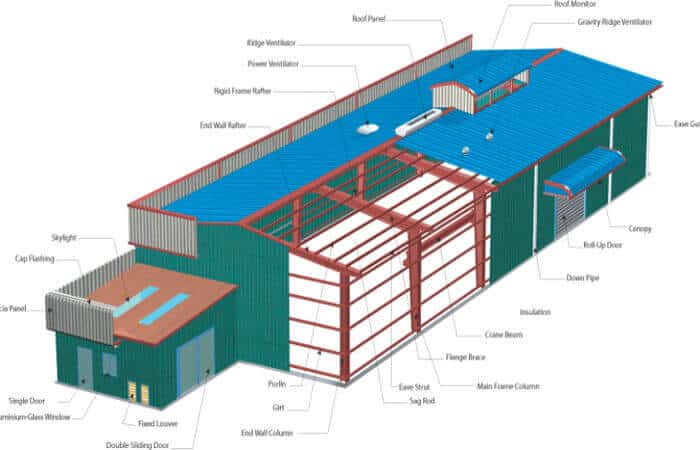

The Composition of the Portal Frame Steel Building Structure:

The portal frame steel building structure mainly comprises steel columns, wind columns, parapet columns, roof steel beams, crane beams, inter-column bracing, horizontal roof bracing, wall girt, roof purlins, tie bars, and other components. The primary structure is the steel column and beam. The portal steel frame can be single-span or multi-span, and its span can be between 18 and 36m.

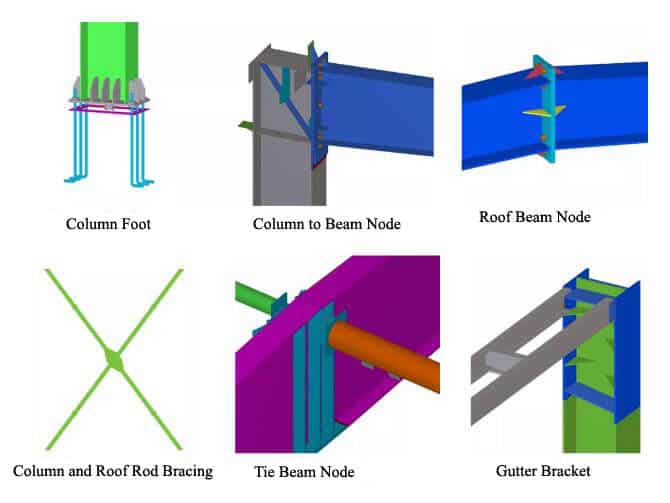

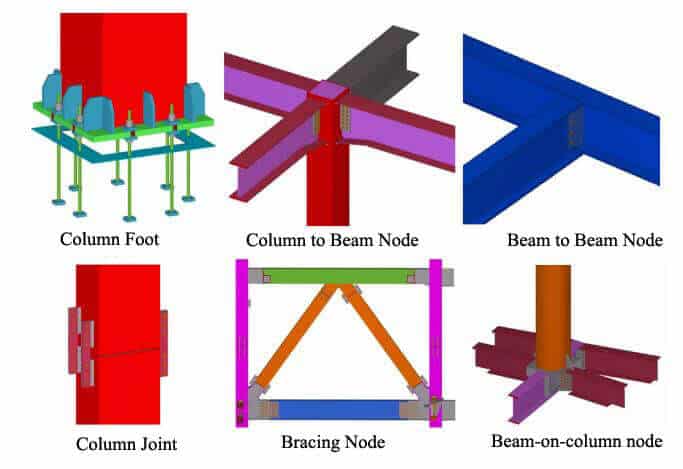

Common nodes of portal frame

The portal steel frame’s particular nodes include the column foot node, beam, column-to-beam node, roof beam node, column and roof bracing, tie beam connection node, and gutter bracket.

The composition of the steel frame structure

For the steel frame structure, with the increase of layers and height and bearing a sizeable vertical load, the lateral resistance (wind load, earthquake action, etc.) requirements become the primary bearing characteristics of the frame.

The steel frame structure system is generally divided into frame structure, frame bracing structure, frame shear wall structure, and frame tube structure.

Frame structure: The frame comprises columns and beams bearing vertical and lateral forces. Steel columns generally use H-shaped steel, box-shaped steel columns, or steel tube concrete columns.

Frame bracing structure: The frame comprises columns and beams, and bracings are provided between the columns to resist lateral forces.

Frame shear wall structure: similar to the frame bracing structure, except that the bracing is replaced with a shear wall to resist lateral forces.

The shear wall is generally a concrete slab, steel plate, or a steel-concrete composite structure with better lateral stiffness than bracing. It is more flexible in layout and suitable for higher building structures.

Frame tube structure: The structure generally comprises a reinforced concrete core tube and an outer ring steel frame.

The system form uses pure steel frames in the horizontal direction and arranges an appropriate number of vertical inter-column bracing in the longitudinal direction to strengthen the longitudinal rigidity, reduce the amount of steel used in the frame, and form a larger space.

Common nodes of steel frame structure

Common nodes of steel frame structure include the column foot node, beam-to-column node, beam-to-beam node, the node of column joint, bracing node, beam-on-column node, etc.

The composition of the steel truss structure

The truss is a structure formed by a plurality of rods hinged connected at each rod’s end and divided into a plane truss and a space truss. The sectional form of the parts includes tube truss, H-shaped steel truss, box-shaped truss, angle steel truss, etc. The truss generally comprises upper chords, lower chords, vertical rods, web robes, and bracing between trusses. The steel used for the truss is less than that of the H beam, the structure has a lighter weight, and the rigidity is greater. It is widely used in high-rise buildings, large-span structures, and bridges.

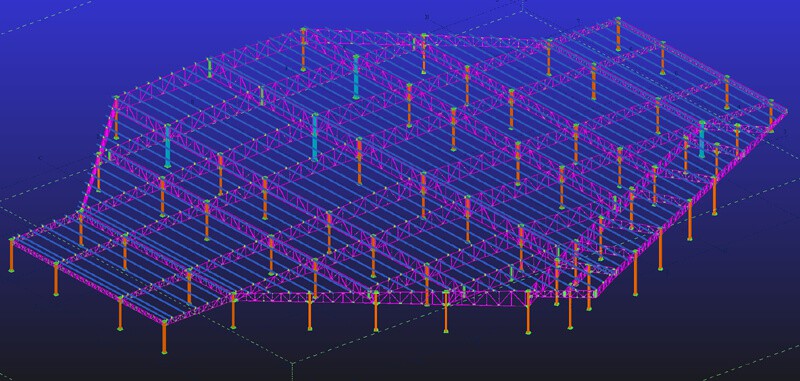

The composition of the Steel grid structure

The grid is a spatial structure that connects multiple rods with nodes in a specific grid form. There are many types of grids, which are classified according to different standards. The various composition methods are divided into cross-truss system grids, triangular cone system grids, quadrangular cone system grids, and hexagonal cone system grids. The flat grid mainly comprises chords, diagonal webs, intermediate nodes, support nodes, etc.

Popular Trends of Steel Structure Buildings

1. Sustainability and green buildings

Steel structure buildings represent the green and low-carbon construction industry, which is conducive to forming a new construction method with high efficiency, high quality, low consumption, and low emissions. They also transform and upgrade the construction industry and realize green and low-carbon development.

By promoting steel structure buildings, we can reduce the excessive use of resources, eliminate waste problems, reduce damage to the ecological environment, make real efforts to protect the environment, and build a green and environmentally friendly home.

Case: Nanjing Yangtze River International Conference Center. The project adopts the “steel frame + steel support” prefabricated steel structure system. Through the large-scale application of steel beams, steel trusses, steel stairs, and steel tube concrete columns, the prefabrication rate of this project reached 70%. The three-glass two-chamber glass curtain wall with excellent thermal performance and the exterior wall and roof with excellent thermal insulation performance were selected, which reduced the demand for air conditioning and heating in the building, which accounts for the highest proportion of building energy consumption, by more than 20%.

2. The rise of modular and prefabricated buildings

Steel structures are essential in modular building design due to their high strength, light weight, and easy prefabrication and assembly. Steel modular buildings achieve a high degree of integration of structure and building functions, providing an effective solution for meeting the needs of high-efficiency, high-precision, and high-quality buildings.

Case: 461 Dean Street in New York, USA, is the world’s tallest modular steel structure building. It is a 32-story residential building in Brooklyn designed by the New York architectural firm SHoP. The building stacks 363 prefabricated apartments like Tetris. This is undoubtedly a tremendous architectural feat, but it is also an essential test of the potential of modular design to make urban housing prices affordable.

3. High-rise and long-span buildings

Steel structure buildings have the advantages of being lightweight and high-strength and have been widely used in high-rise and large-span buildings. Modern architectural design pursues larger and more open spaces, such as stadiums, airports, and convention centers, and steel structures can provide long-span support.

Case: Beijing’s Bird’s Nest (National Stadium) the large-span steel structure of the National Stadium adopts a large number of box-shaped components welded from steel plates. The cross-arranged main structure and the secondary structure of the roof and facade together form the special architectural shape of the “Bird’s Nest.” The maximum span reaches 332.3 meters, making it one of the largest sports buildings in the world.

4. Earthquake resistance and safety

Steel structure buildings have good ductility and can offset the energy consumption of seismic waves. According to calculations, the strength of steel is about 8 times that of concrete and its density is only 3.2 times that of concrete. Therefore, for the same bearing capacity requirements, the weight of steel structures can be much lighter than that of concrete components. In addition, the cross-sectional utilization rate of steel components is high. Generally, when building high-rise buildings, the use of steel structures can reduce the weight of the structure by about 40%-50%. Buildings that have successfully lost weight have high strength and are naturally not afraid of earthquakes.

In Chengdu, the earthquake resistance and safety of steel building structures have been recognized. Japan is a country with many earthquakes, and the share of steel structures in Japan has reached about 65%.

Case: The main structure of Tokyo Skytree in Tokyo, Japan adopts a hybrid structure system consisting of steel tube concrete columns and steel beams. The lower third of the column is fixed to the tower body with steel, and the upper two-thirds is a movable part, which is structurally independent of the tower body and is only connected to the tower body through an oil damper.

When an earthquake occurs, the shaking of the entire tower cancels each other out due to the different shaking periods of the tower body and the core column. According to simulation calculations, the core column can reduce the shaking of the Skytree by up to 50% during an earthquake and about 30% during strong winds.

5. Architectural aesthetics and innovative design

The high strength and light weight of steel structure buildings enable designers to create buildings with diverse shapes. Arches, cantilevers, folds and other forms have been widely used in steel structure buildings. These forms not only enhance the visual impact of the building, but also give the building a unique sense of movement and rhythm. This variety of forms and lines adds a rich sense of layering and three-dimensionality to the architectural aesthetics.

Case: Shenzhen DJI’s Sky City Building is a classic architectural aesthetics case, which overturns the traditional concept of office space and builds a new creative community in the air.

The structural system adopts a “supported steel frame structure system with a suspended layer”. The steel frame structure supporting cylinder is used as the main lateral resistance system. At the top of each suspended body, combined with the facade support layout, multi-layer inclined cantilever trusses are set, and the lower floors are suspended on the cantilever trusses through suspension columns.

Steel Building Structures VS. Reinforced Concrete

| Comparison | Steel Building Structure | Reinforced concrete structure |

| Material composition | Mainly steel (steel beams, steel columns, steel plates, etc.) | Concrete + steel bars |

| Structural weight | Light weight (30%-50% lighter than concrete) | Heavy weight |

| Construction speed | Factory prefabrication + on-site installation, fast construction speed | More wet operations on site, long construction period |

| Adaptability to construction environment | Not affected by seasonal temperature, all-weather construction | Low temperature and rainy season are not conducive to concrete pouring and maintenance |

| Seismic performance | Lightweight and high strength, good structural ductility, strong seismic resistance | High stiffness but poor ductility, relatively weak seismic performance |

| Structural span | Suitable for large-span structures, such as stadiums and airport terminals | Suitable for small and medium-span structures |

| Material recycling | Steel can be 100% recycled and reused | Concrete cannot be recycled and becomes construction waste after demolition |

| Environmental protection performance | Green and environmentally friendly, in line with the trend of prefabricated and low-carbon buildings | High energy consumption in cement production, large dust and noise pollution |

| Cost | Steel prices fluctuate greatly, the initial cost is slightly higher, but the cost of the entire life cycle is low | The initial construction cost is low, but the maintenance and reinforcement costs are high |

| Durability | Susceptible to corrosion (anti-corrosion measures are required), high maintenance costs | Strong durability, basically no special maintenance required |

| Flexibility | Flexible structural layout, suitable for later reconstruction and expansion Fixed structure, difficult reconstruction and expansion Building function First choice for industrial buildings, super high-rise buildings, large-span buildings, temporary buildings | Common in ordinary residential buildings, office buildings, low-rise factories |