The service life of steel structure buildings is more than 50 years. The roof and wall panels of prefabricated steel…

The frame structure is more common among steel structure multi-story building. The multi-floor steel frame structure comprises beams and columns, and most of the nodes are rigidly connected. The frame structure is a typical vertical load-bearing structure.

Design of Steel Structure Multi-story Building:

Floor Structure

The floor has sufficient stability, strength, and rigidity. At the same time, the thickness of the floor slab should be reduced to increase the net height of the indoor. Corrugated metal floor deck-concrete composite floor covers are currently widely used.

The construction speed is breakneck, the plane rigidity is also considerable, and the net height of the building effectively improved. The general method is to lay the metal floor deck on the steel beams and then cast 100-150mm concrete on site. By welding enough shear studs on the steel beam, the steel beam and concrete can work together to form the floor.

Wall Materials

Lightweight wall materials have better thermal insulation and sound insulation performance. Currently, wall structures are mainly divided into self-supporting and non-self-supporting types.

Self-supporting walls generally use aerated concrete blocks, which are used as external walls. Light concrete board, gypsum board, cement particle board, used as the interior wall.

The external non-self-supporting wall materials generally include the corrugated single color sheet, sandwich panels, glass fiber reinforced exterior wall panels, and so on.

If non-self-supporting wall materials are used, wall girt should be installed to hang the outer protective structure. Wall girt usually use C or Z cold-formed thin-walled steel, and the span and wall distance determine the size.

Different type of Steel Structure Multi-story Building :

Steel Frame Structure System

In the vertical and horizontal directions of the building, the steel frame structure is used as the structural system for load-bearing and lateral force resistance. The connection between steel beams and steel columns can be rigid, semi-rigid, or hinged. The load-bearing capacity and lateral force resistance of this structure are provided by the rigid-connected frame suitable for systems with large column spacing and no support.

The frame structure is flexible and diversified in plan layout, without load-bearing walls, providing a larger indoor space for the building. At the same time, the building functions are easy to meet, the space usage is more convenient and flexible, the building facade design is also relatively free, the structural components are easy to standardize production and construction.

Steel Frame Bracing System

It refers to the frame as the basic structure, and a certain number of bracing are arranged along with the longitudinal, transverse, and other main axis directions of the building.

The frame-bracing system serves as a dual anti-side force system. In the event of an earthquake, the structure automatically adjusts its internal force, which serves the purpose of two seismic fortifications and enhances the safety performance of the system.

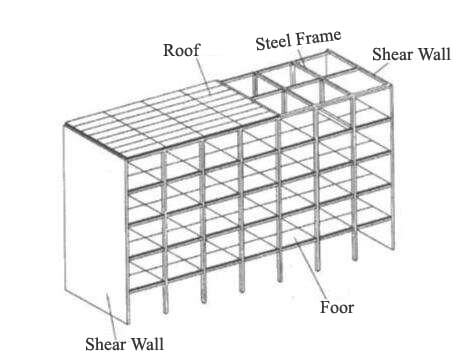

Steel Frame Shear Wall System

A structural system in which a certain number of shear walls are arranged in a frame structure to make the frame and shear walls work together to resist horizontal loads.

In the frame-shear wall system, the frame mainly bears vertical loads and a small number of horizontal loads, so the cross-sectional size is reduced compared to the frame system. However, it still has the characteristics of the flexible layout of the frame and convenient use. At the same time, due to the existence of the shear wall, it can bear more than 80% of the horizontal shear force, which significantly improves the lateral stiffness of the structure.

Steel Frame Hull Core Structure System

The shear wall structure arranged around the inner core to form a closed core structure system or the vertical bracing are placed along the periphery of the core area. And steel frame surrounding the outside of the structure. The frame-core is widely adopted in high-rise buildings and has also been applied in multi-story steel structure buildings in recent years.

The core structure has excellent lateral rigidity and strong torsion resistance. Generally, it is used as an elevator, stairwell, or bathroom. It not only improves the utilization rate of materials but also achieves practical effects in construction. The collaborative work of the hull core and the frame can quickly meet the limits of the inter-layer displacement and the overall deformation of the structure.

Advantages of Steel Structure Multi-story Building:

Good seismic performance:

Due to the excellent ductility of steel, it can not only weaken the earthquake response but also make the steel structure have the ability to resist substantial earthquake deformation.

Lightweight:

It can significantly reduce the vertical load and seismic action transmitted from the frame structure to the foundation.

Make full use of building space:

Due to the small column section, the building area can be increased by 2~4%.

The construction speed is fast:

A large space is formed, the plane layout is flexible, the rigidity of each part of the structure is relatively uniform, the system is simple, and the construction is easy.