Metal Cladding System

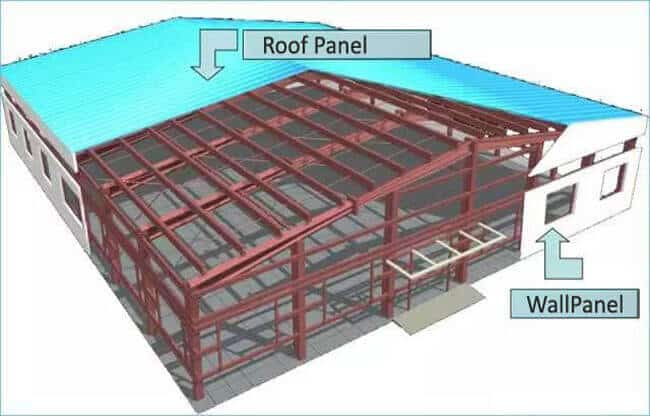

The metal cladding system includes wall cladding, roof cladding, skylight sheet, flashing and trim, gutter as well as insulation materials. They are essential components of steel structure building, which determines the appearance, waterproof, and thermal insulation of the building.

The components of Metal Cladding System

Metal cladding system include Corrugated Metal Sheet, Glass Wool Insulation, Skylight Sheet, EPS sandwich panel, Glass Wool/Rock Wool Sandwich Panel and Polyurethane (PU) Sandwich Panel.

How to Trim Metal Building

The Trim and flashing of the metal building, which mainly uses for waterproofing. Generally refers to the colored metal sheet…

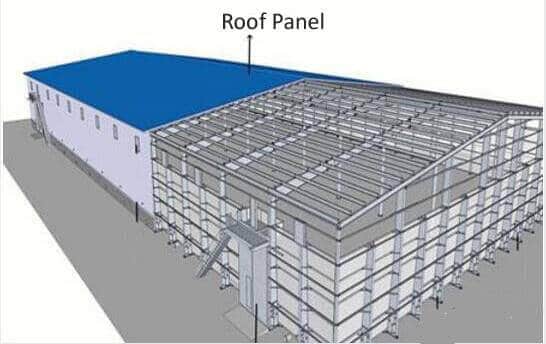

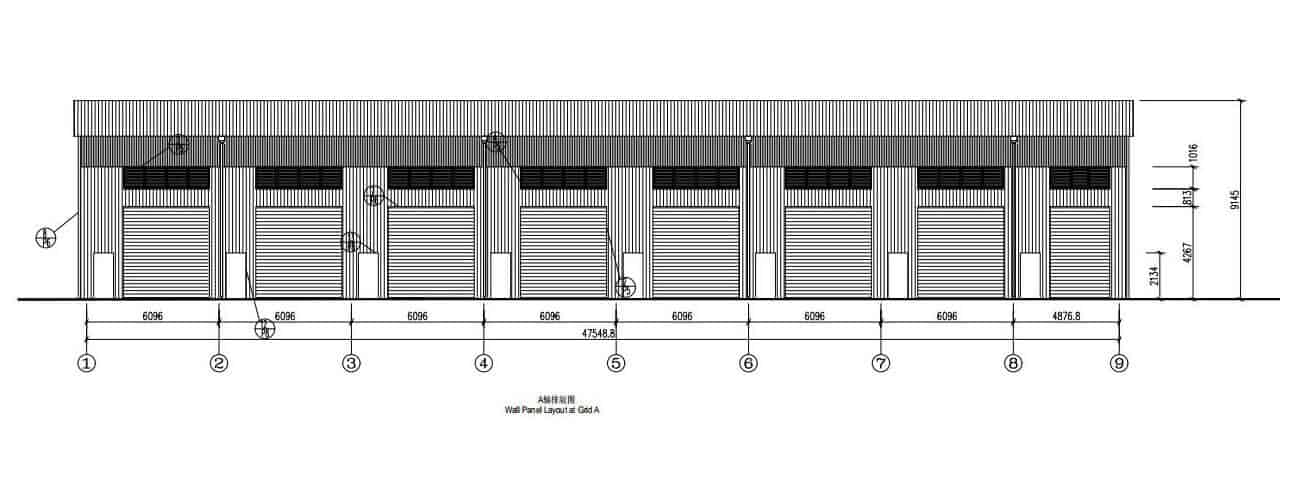

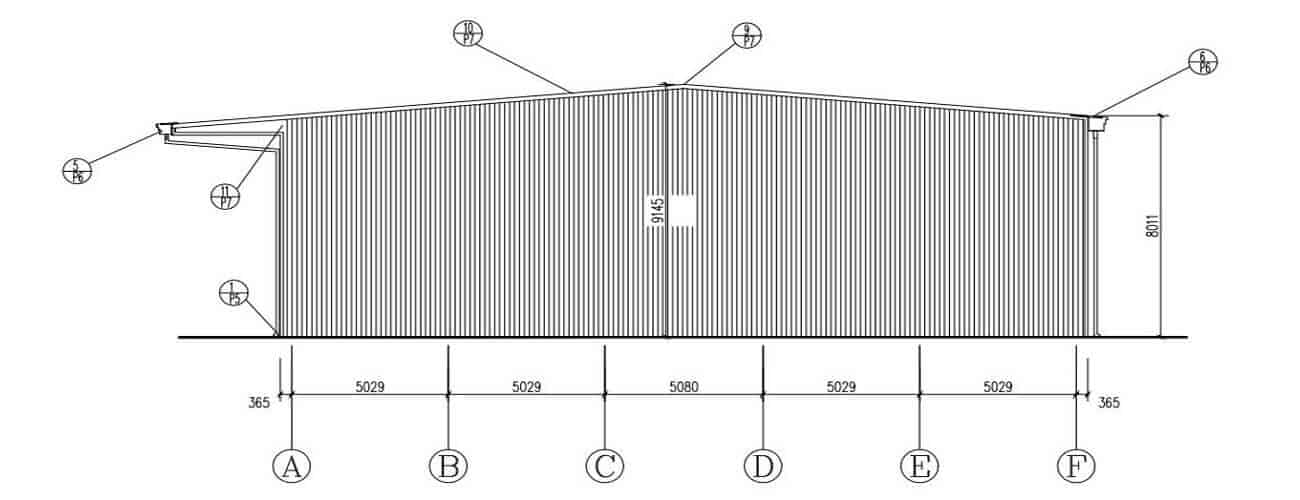

The installation of Wall Panel

The step of wall panel installation, which is applicable to guide the construction process of on-site, the installation of sandwich…

Steel Building Accessories

During the installation process of the wall and roof system, steel building accessories use to ensure the panels fixed to…

Trim and Flashing for Metal Cladding System

The trim and flashing used for waterproofing. Generally refers to the colored metal sheet bending parts at the door, window, corner, eaves, canopy and other parts of steel structure buildings

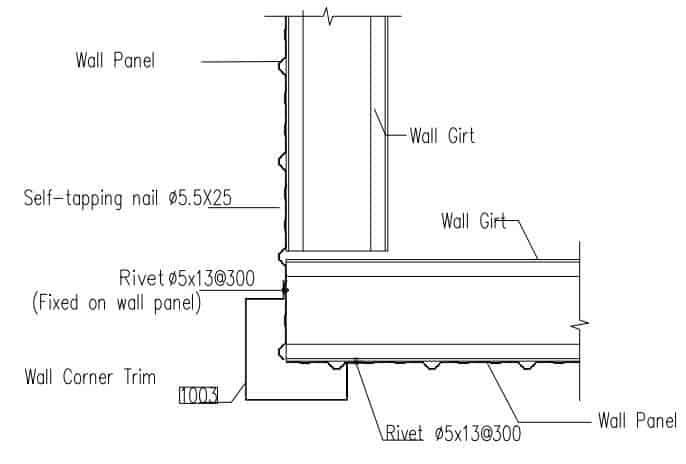

Wall Corner Trim

The Wall corner trim is placed at the corners of the exterior walls of the metal building to cover the joints where the sidewalls and the end wall panels meet for waterproofing and decoration.

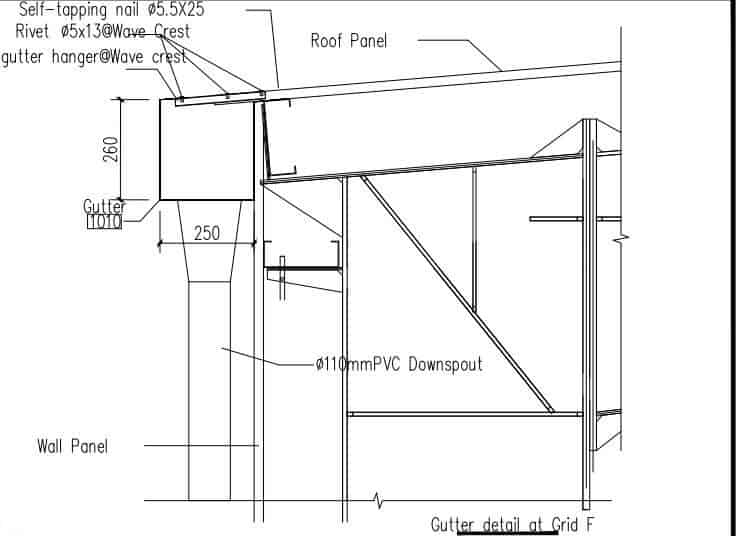

Gutter

The gutter is an essential component of the roof drainage system, which is used to collect rainwater and drain it through the downspout temporarily. The overlap of the gutter is 100mm, and rivets connect the overlap.

Gutter classification:

1. steel plate.

2. galvanized plate.

3. stainless steel.

4. metal color sheet.

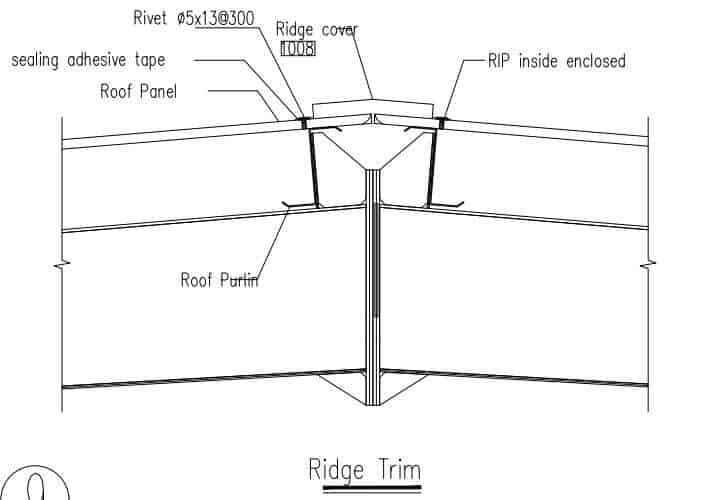

Roof Ridge Cap

The metal ridge trim is at the highest point of the ridge, where the two roof panels overlap, the trim arranged along the hill, where the two ribs intersect.

The ridge trim cap is erects after the roof panel finishes installing.

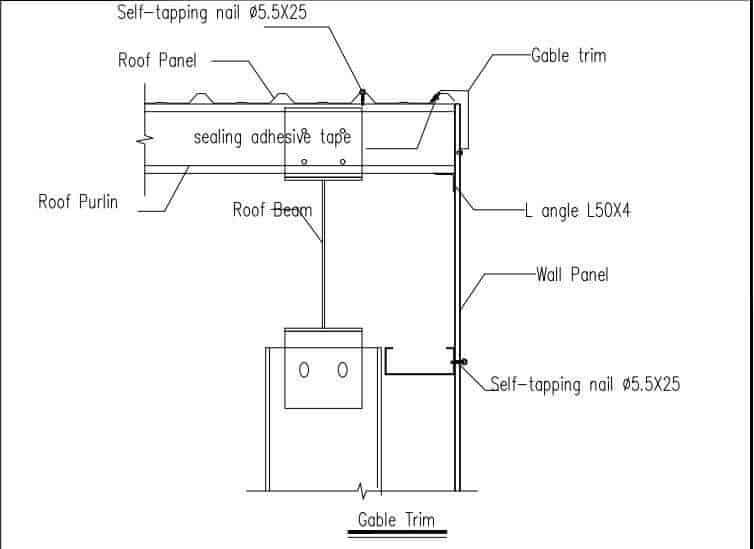

Gable Trim

The angle of the gable trim matches the slope of the gable roof and covers the joint formed by the intersection of the roof panel and the end wall panel on the steel building, and there is no overhang at the roofline.

The combination of the gable trim and sealant provides a waterproof seal for your roof system.

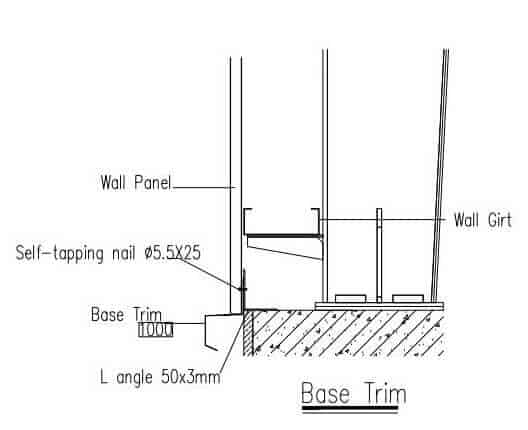

Base Trim

The base trim is a barrier between the bottom of the exterior wall cladding and the foundation. Angle steel bolted to the edge of the concrete floor. The base trim is connected to the angle steel, forming a ledge under the exterior wall panel.

The Base trim uses to prevent the bottom of the wall panel from contacting the concrete slab and protect the metal sheet, and

cover the irregularities of the foundation edges to make the foundation edges more neat and beautiful

Wall Corner Trim

The Wall corner trim placed at the exterior walls corners of the metal building to cover the joints where the sidewalls and the end wall panels meet for waterproof and decoration.

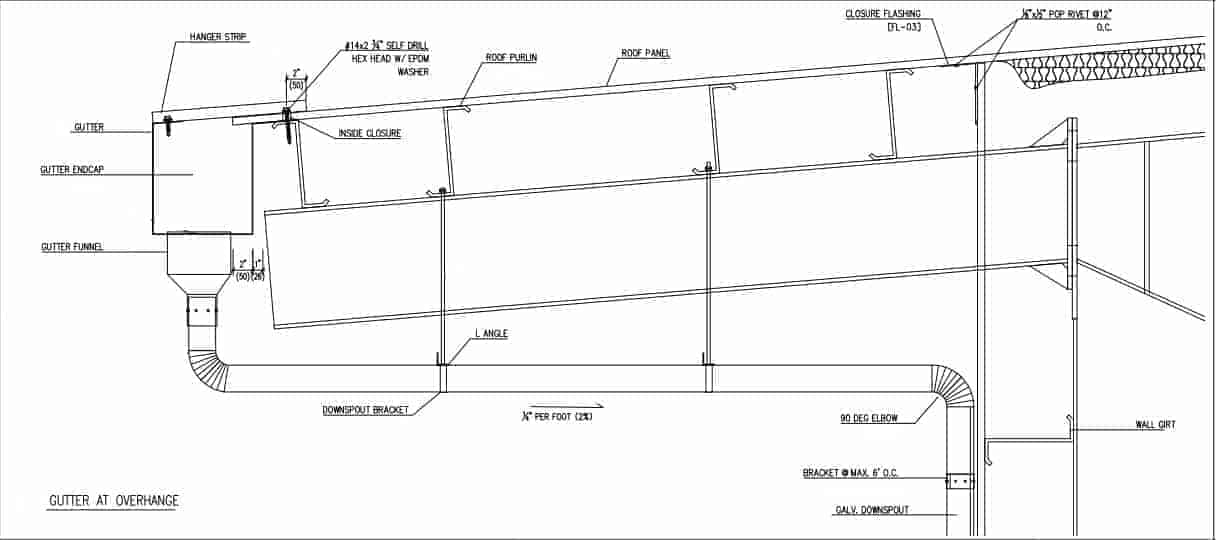

Gutter at Overhang

The gutter at overhang is connected with the roof panel, with the wall panel as the dividing line, the one associated with the cantilever beam, and the beam’s outer edge as the dividing line. The overhanging gutter is outside the edge of the external wall or the edge of the beam.

Gutter classification:

1. steel plate.

2. galvanized plate.

3. stainless steel.

4. metal color sheet.

Metal Cladding System-Corrugated Color Metal Sheet

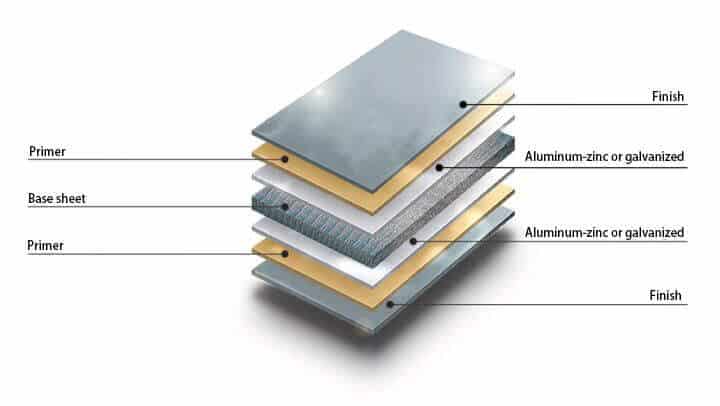

The composition of corrugated color metal sheet:

The color metal sheet is generally composed of base sheet + aluminum-zinc or galvanized + color coating.

1. Base sheet

1. Base sheet

The base sheet material ranges from a yield strength of 300Mpa to 550Mpa, and a thickness from 0.3mm to 0.8mm.

2. Aluminum-zinc or galvanized

There are two types of anti-corrosion coatings: aluminum-zinc (55% aluminum) and galvanized. Among them, aluminum-zinc sheet has better anti-corrosion performance. Therefore, if used for roof panels, it does not need to be overlaid with color coating, and the original color of aluminum-zinc plating can be used directly. Of course, the color coating can also be added to the aluminum-zinc sheet; the anti-corrosion performance of galvanizing is slightly worse. But because aluminum is expensive, zinc is cheap, and the amount of galvanized coating is increased, it is also a good choice for the anti-corrosion performance of color-coated color steel sheets.

3. Coating types

1). Types of finish

Polyester (PE)

Silicon modified polyester (SMP)

High Weather Resistance Polyester (HDP)

KYNAR@500: Contains 70% polyvinylidene fluoride (PVDF)

2). Types of primer

Epoxy resin (EP, EPoxy resin)

Polyester (PE, PolyEster)

Polyurethane (PU, PolyUrethane)

How To Install Metal Cladding Panel

In recent years, metal buildings widely used in workshop and warehouse buildings, exhibition halls, and office buildings, which due to the low steel consumption, fast and straightforward installation, and a high degree of industrial production. It promoted the development of the metal cladding system, which from singularity to diversification, and then triggered a change in new design and installed the metal building cladding panel. The metal cladding system of steel…

1. Base sheet

1. Base sheet