A steel portal frame structure is a type of low-rise building composed of steel columns and rafters joined by rigid…

Defining the Steel Frame in Modern Architecture

At the heart of many contemporary buildings lies a structural system defined by its strength, adaptability, and efficiency: the steel frame. This framework, composed of columns, beams, and bracing elements joined through welding, bolting, or riveting, provides essential support across a wide range of architectural forms. Its success stems not only from the inherent strength of steel but also from its ability to accommodate complex loads and geometries with precision.

Why Steel? Material Advantages in Contemporary Construction

The use of steel in construction is far from arbitrary. Its high strength-to-weight ratio allows for slender yet robust load-bearing systems, which ease foundation requirements and expand usable interior space. Unlike concrete, steel components are manufactured under controlled conditions, enabling superior quality control and faster on-site assembly. While the initial cost may exceed that of traditional materials, the long-term economic gains—fewer maintenance interventions, enhanced adaptability, and recyclability—make it a strategic investment.

Cross-Sector Applications: Where Steel Frames Matter Most

Steel frame systems are the structural backbone of numerous sectors:

- Industrial Operations: From heavy-duty workshops to logistics centers.

- Infrastructure: Long-span bridges that demand both flexibility and strength.

- Public Venues: Stadiums and event halls requiring unobstructed spaces.

- Commercial Real Estate: Multi-story malls and office towers with evolving spatial needs.

This versatility stems from steel’s capacity to reconcile architectural ambition with engineering practicality.

Typologies of Steel Frame Systems

Types of steel frame structures

1. Rigid Frame: Endurance Through Connection

Rigid frames employ moment-resisting joints to ensure the structural elements act together under load. Their capacity to absorb lateral forces makes them ideal for buildings in seismic regions or exposed to wind pressure. They are particularly suited for multi-story structures where vertical continuity and lateral stability are crucial.

2. Portal Frame: Efficiency in Single-Story Spans

In single-story industrial buildings, the portal frame reigns supreme. Its straightforward form—composed of rigidly connected columns and rafters—permits large spans without internal supports. This structural logic simplifies construction and optimizes material use, making it a favored solution for warehouses, workshops, and hangars.

3. Truss System: Strength from Geometric Ingenuity

Trusses exploit triangular geometry to distribute forces efficiently through minimal material use. By connecting upper and lower chords with diagonals, trusses achieve impressive spans and are commonly seen in stadiums, airport terminals, and long-span roofing. Their lightweight nature reduces the demands placed on foundations, cutting both cost and complexity.

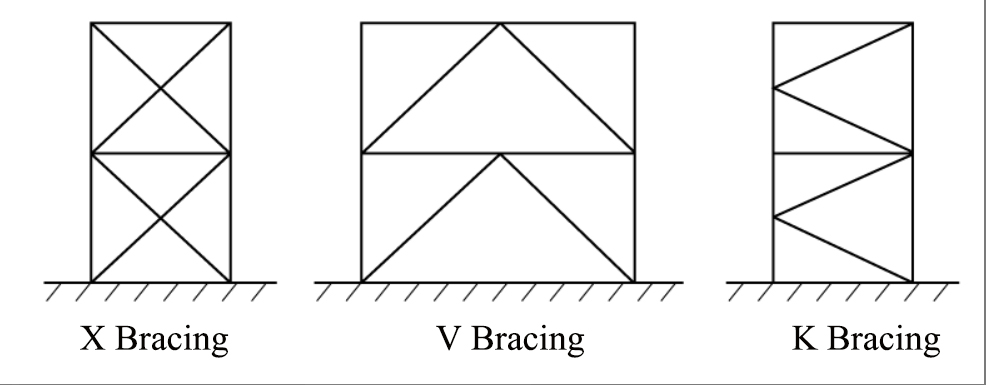

4. Braced Frames: Reinforcing Stability

In high-rise and slender buildings, braced frames provide the extra stiffness required to resist lateral loads. Bracing—often arranged in X, V, or K formations—supplements the primary frame, allowing the structure to absorb seismic and wind-induced forces without excessive deformation.

Core Principles in Steel Frame Design

Structural Logic and Load Path Analysis

A sound steel frame begins with understanding how forces traverse the structure. Engineers calculate live loads, dead loads, environmental factors, and dynamic impacts to ensure loads are transferred smoothly through beams and columns to the foundation. Misjudging these paths can result in local stress concentrations that jeopardize safety and durability.

Material Selection: Matching Steel to Function

Grade Q355B—a high-strength, low-alloy structural steel—is commonly used due to its excellent mechanical performance and weldability. The cross-sectional profile is equally important. For applications requiring high torsional resistance or extreme spans, box sections are often preferred over standard H- or I-beams due to their superior rigidity and buckling resistance.

Connection Detailing: More Than Just Fastening

Connections are the keystones of steel frame performance. Whether through full-penetration welds or high-tension bolts, these joints must balance rigidity and flexibility. Careful detailing ensures the structure behaves as intended under both service loads and exceptional events such as earthquakes or heavy impacts.

Material Variants: Hot-Rolled vs. Cold-Formed Steel

The selection between hot-rolled and cold-formed steel is dictated by function:

- Hot-rolled steel, produced at elevated temperatures, offers superior ductility and load-bearing capacity. It’s used for beams, columns, and structural cores.

- Cold-formed steel, shaped at ambient temperatures, is lighter and suited for non-structural elements such as purlins and girts. Its cost-effectiveness makes it a practical choice for low-load environments.

Each material has its place, and thoughtful integration of both is often the hallmark of an efficient and cost-effective design.

Conclusion: The Enduring Value of Steel Frame Construction

The steel frame stands as one of the most refined achievements of modern structural engineering. It brings together strength, efficiency, and adaptability in a way few other materials can match. Whether used in a warehouse, a stadium, or a skyscraper, a well-designed steel frame responds not only to today’s construction challenges but also anticipates the demands of tomorrow—delivering long-term value through performance, resilience, and sustainability.

Frequently Asked Questions (FAQs)

1. What makes steel frame structures more efficient than traditional concrete systems?

Steel offers a lighter structure with higher strength, faster construction timelines, and greater design flexibility—especially for large-span and multi-story projects.

2. In which sectors are steel frame systems most prevalent?

Steel frames are extensively used in industrial warehouses, public venues like stadiums, commercial high-rises, and bridges requiring long-span solutions.

3. What’s the structural difference between a rigid frame and a portal frame?

Rigid frames focus on multi-story stability with moment-resisting connections; portal frames are optimized for large-span single-story buildings with simple, efficient load transfer.

4. Which steel grade is typically used in frame construction?

Q355B is commonly chosen for its balance of strength, ductility, and weldability, meeting the structural demands of both industrial and commercial buildings.

5. Are steel frame structures suitable for seismic zones?

Yes. Steel’s ductility and capacity to dissipate energy through joints make it exceptionally well-suited to seismic design.

6. What determines the choice between hot-rolled and cold-formed steel?

Hot-rolled steel is used for primary load-bearing elements, while cold-formed steel is ideal for lighter, secondary framing components.

7. How long does it typically take to construct a steel frame building?

Depending on complexity, steel frame buildings can be assembled 30–50% faster than those using traditional construction methods.

8. Is steel construction environmentally responsible?

Absolutely. Steel is fully recyclable, and its efficient use reduces material waste and promotes sustainable building practices.