Steel structure splicing includes splicing in the workshop and on-site. The splicing methods include welding and bolting. We should implement…

The types of steel building structures are the portal rigid steel frame, the frame structure, the truss structure, and the grid structure. Understanding the advantages and disadvantages of different structural systems is essential to design your project correctly. The forms of stress are also different.

Features and applications of the standard type of steel building structures:

- The Portal frame structure is a form of a closed structural system. It has a simple force, clear force transmission path, and fast construction speed. Introducing a portal frame structure strengthens the bonding properties of walls and generates more flexible space layouts, thus providing more possibilities for engineering creativity.

- Steel building frame structures are used to construct high-rise and super high-rise buildings, multi-story buildings, and commercial office buildings with the flexibility of their structure. A steel building frame can be adjusted to suit your needs.

- The advantage of Steel Truss Structure is that small cross-section rods can be used to form larger cross-section components, which are often used in industrial and civil buildings such as roofs, bridges, TV towers, mast towers, marine oil production platforms, tower corridors, etc., with large spans or heights In the building.

- The Steel Grid Structure is a high-order, statically indeterminate space structure composed of many rods according to specific rules. The space is small in force, light in weight, rigid, and has good seismic resistance. It can be used as a gymnasium, exhibition hall, rain roof, and canopies and hangars.

1. Portal Frame Steel Building Structures

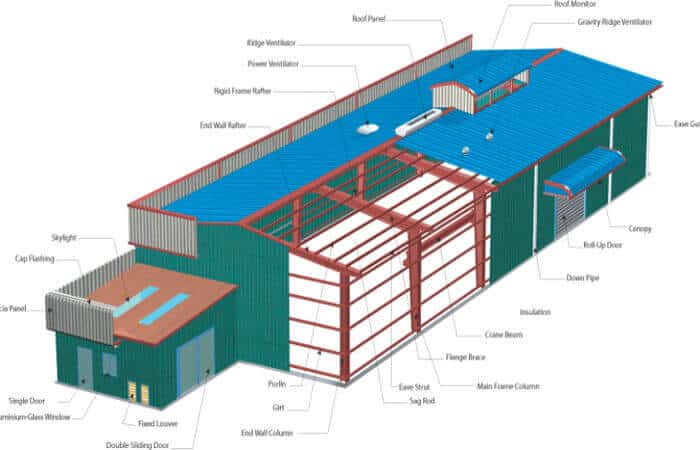

The portal steel frame comprises hot-rolled or welded section steel, cold-formed C/Z steel, and steel pipe as the main force-bearing components and adopts a light roof and wall structure. The Portal frame is the most common form of the light steel structure.

The rigid portal frame is a structure with rigidly connected beams and columns. It has the characteristics of a simple structure, lightweight, reasonable stress, and simple construction. Therefore, it is widely used in industrial, commercial, agricultural, and Institutional Buildings.

2. Steel Building Frame Structures

The steel frame structure comprises beams and columns that can withstand vertical and horizontal loads. Columns, beams, bracing, and other members are rigidly or hingedly connected to form a flexible layout and create a larger space. It is widely used in multi-story, high-rise, super-highrise buildings, commercial office buildings, conference centers, etc.

3. Steel Truss Structure

The steel truss structure comprises several rods hinged at both ends of each rod. It can be divided into a plane truss and a space truss. According to the parts section, it can be separated into tube truss and angle steel truss. The truss generally comprises the upper chord, lower chord, vertical rod, diagonal web, and inter-truss support. The steel used in trusses is less than that of solid web beams, the structural weight is lighter, and the rigidity is greater.

The advantage of the steel truss is that it is used to form more significant members with smaller cross-sections. It is often used in roofs, bridges, TV towers, mast towers, marine oil platforms, and tower corridors of industrial and civil buildings.

4. Steel Grid Structure

According to a specific rule, the grid structure comprises many rods with minor space stress, are lightweight, have high rigidity, and offer excellent seismic resistance. It is used as a gymnasium, exhibition hall, and aircraft hangar.

5. Cold-formed thin-walled steel building structures

Cold-formed thin-walled steel structures refer to finished steel products with various cross-section shapes bent from steel plates or strips with a thickness of 1.5 to 6 mm in a cold state. Cold-formed steel is an economical cross-section of lightweight, thin-walled steel, known as steel cold-formed or cold-formed profiles.

In industrial, civil, and agricultural buildings, thin-walled steel building structures can make various structures and components, such as roof trusses, rigid frames, grids, purlins, wall beams, and columns.

Application of cold-formed thin-walled steel structure.

- Cold-formed thin-walled steel can be used as main load-bearing components such as steel frames, trusses, beams, and columns.

- Cold-formed thin-walled steel is used as secondary components and enclosure structures such as roof purlins, wall frame beams and columns, keels, doors and windows, roof panels, wall panels, floor slabs, etc.

- Cold-formed steel-concrete composite structures that use cold-formed steel and reinforced concrete to form composite beams, plates, and columns have also become a new research direction in engineering.

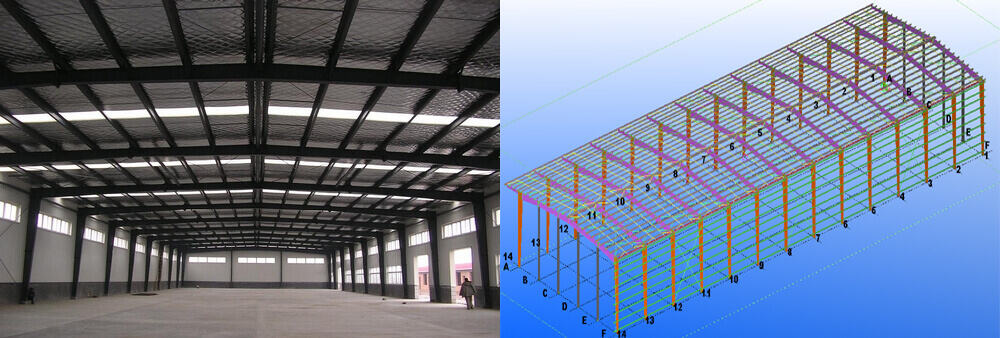

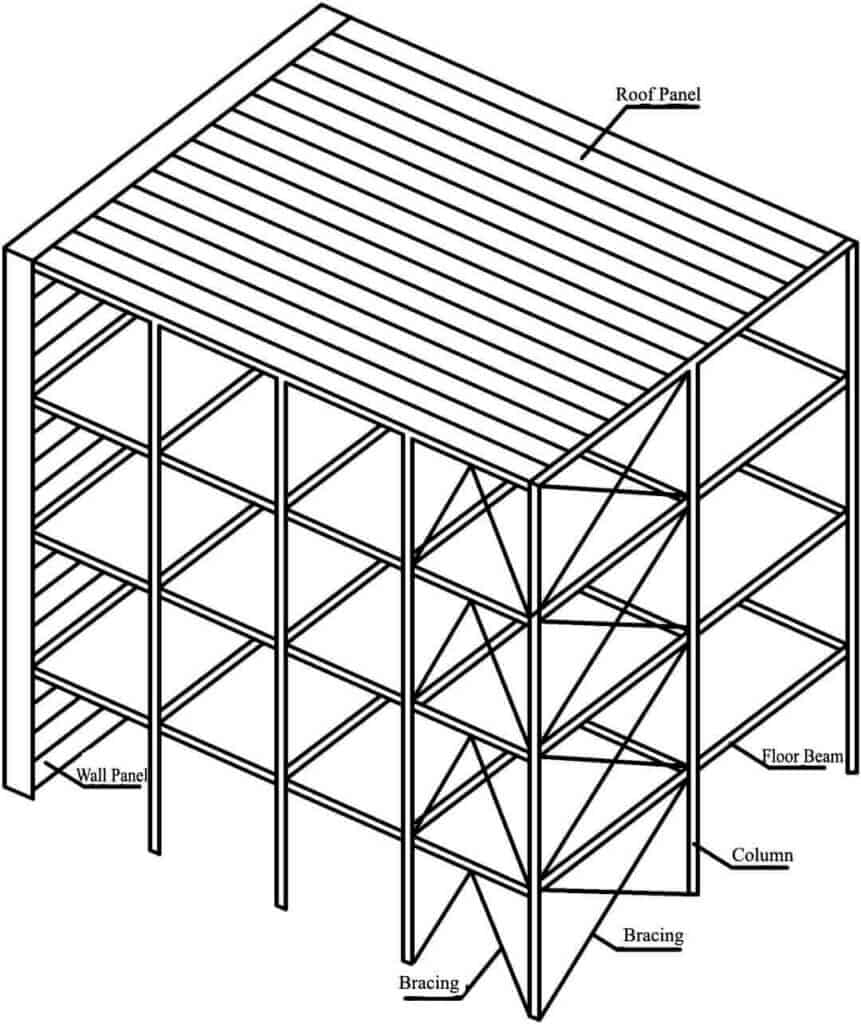

The composition of the portal frame steel workshop system:

Steel structure workshops are divided into light steel workshops and heavy steel workshops. The workshop’s structural system mainly comprises steel columns, wind columns, parapet columns, roof steel beams, crane beams, inter-column bracing, horizontal roof bracing, wall girt, roof purlins, tie bars, and other components. The primary structure is the portal steel frame, which can be single-span, multi-span, or multi-story, with an economic span of about 24-30m.

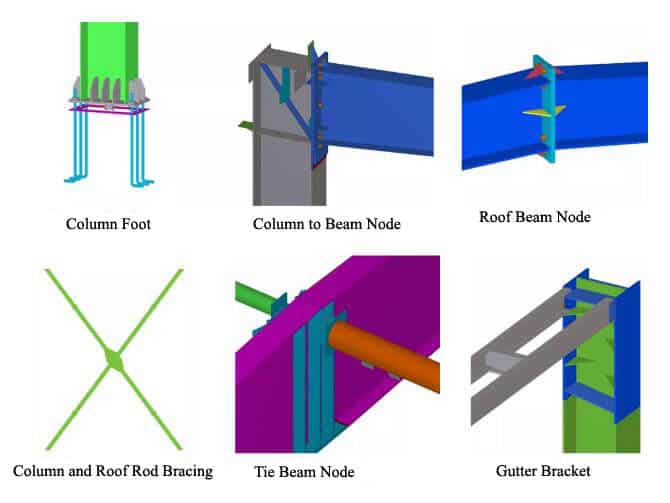

Common nodes of portal frame

The portal steel frame’s particular nodes include the column foot node, beam, column-to-beam node, roof beam node, column and roof bracing, tie beam connection node, and gutter bracket.

The composition of the steel frame structure

For the steel frame structure, with the increase of layers and height and bearing a sizeable vertical load, the lateral resistance (wind load, earthquake action, etc.) requirements become the primary bearing characteristics of the frame.

The steel frame structure system is generally divided into frame structure, frame bracing structure, frame shear wall structure, and frame tube structure.

Frame structure: The frame comprises columns and beams bearing vertical and lateral forces. Steel columns generally use H-shaped steel, box-shaped steel columns, or steel tube concrete columns.

Frame bracing structure: The frame comprises columns and beams, and bracings are provided between the columns to resist lateral forces.

Frame shear wall structure: similar to the frame bracing structure, except that the bracing is replaced with a shear wall to resist lateral forces.

The shear wall is generally a concrete slab, steel plate, or a steel-concrete composite structure with better lateral stiffness than bracing. It is more flexible in layout and suitable for higher building structures.

Frame tube structure: The structure generally comprises a reinforced concrete core tube and an outer ring steel frame.

The system form uses pure steel frames in the horizontal direction and arranges an appropriate number of vertical inter-column bracing in the longitudinal direction to strengthen the longitudinal rigidity, reduce the amount of steel used in the frame, and form a larger space.

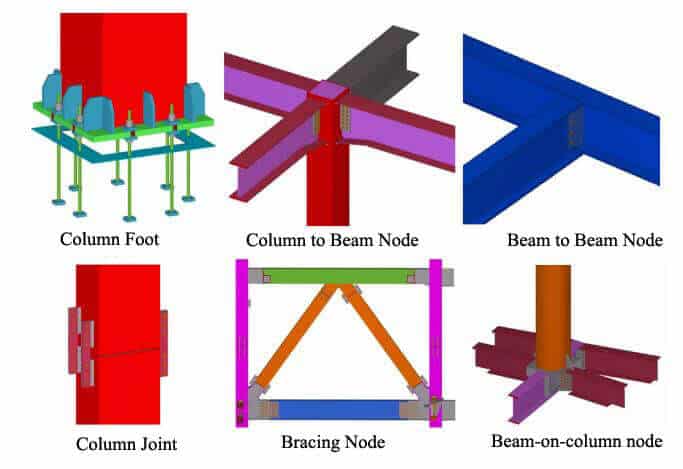

Common nodes of steel frame structure

Common nodes of steel frame structure include the column foot node, beam-to-column node, beam-to-beam node, the node of column joint, bracing node, beam-on-column node, etc.

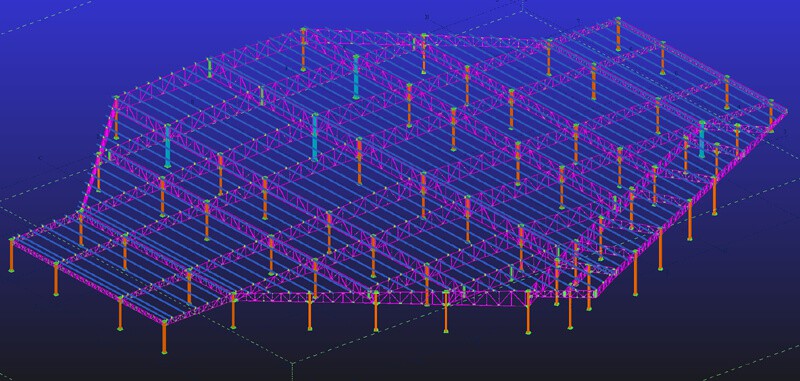

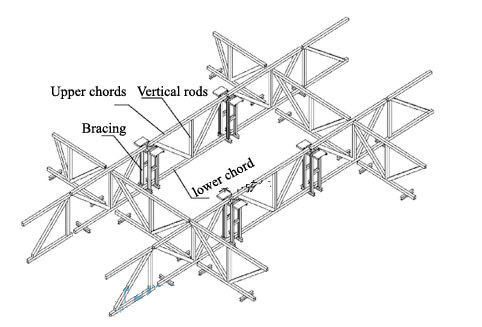

The composition of the steel truss structure

The truss is a structure formed by a plurality of rods hinged connected at each rod’s end and divided into a plane truss and a space truss. The sectional form of the parts includes tube truss, H-shaped steel truss, box-shaped truss, angle steel truss, etc. The truss generally comprises upper chords, lower chords, vertical rods, web robes, and bracing between trusses. The steel used for the truss is less than that of the H beam, the structure has a lighter weight, and the rigidity is greater. It is widely used in high-rise buildings, large-span structures, and bridges.

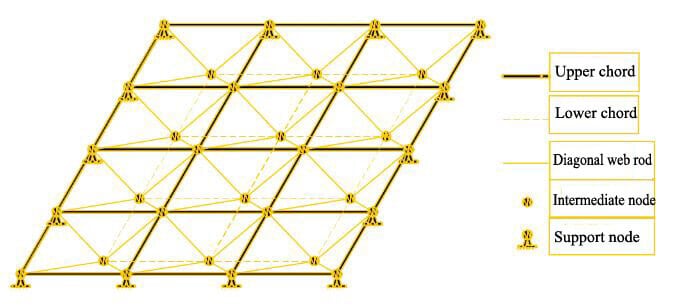

The composition of the Steel grid structure

The grid is a spatial structure that connects multiple rods with nodes in a specific grid form. There are many types of grids, which are classified according to different standards. The various composition methods are divided into cross-truss system grids, triangular cone system grids, quadrangular cone system grids, and hexagonal cone system grids. The flat grid mainly comprises chords, diagonal webs, intermediate nodes, support nodes, etc.

Miracles of Steel – These “world famous buildings” are all steel structure buildings

Steel building structures combine the style and beauty of classical and modern architecture. Many large buildings around the world use steel structure technology extensively. So, what are the famous steel structure buildings in the world? Let’s take a look!

Eiffel Tower

The Eiffel Tower was built in 1889. This hollow structure iron tower is located on the Champ de Mars in Paris, France. It is 300 meters high, with an antenna height of 24 meters and 324 meters.

The tower is a hollow steel frame structure with three-level platforms at an altitude of 57 meters, 115 meters, and 274 meters for tours. The fourth-level platform houses a weather station 300 meters above sea level.

There is an antenna on the top, which is the Paris Television Center. There are elevators and 710 steps from the ground to the top of the tower. It is understood that the tower used more than 1,500 giant prefabricated beams, 1.5 million rivets, and 12,000 steel castings, with a total weight of 7,000 tons. It took 250 workers 17 months to build it.

Millennium Dome

The Millennium Dome, located on the Greenwich Peninsula on the banks of the Thames River in east London, is a landmark building built by the British government to welcome the 21st century.

The diameter of the bend is 320m, and the circumference is more than 1000m. Twelve masts penetrate the roof and reach a height of 100m. The top adopts a spherical tension membrane structure.

The membrane surface is supported on 72 radial steel cables with a cross-section of 2×φ32. The mast supports these steel cables through cable-stayed slings and lanyards spaced 25m apart. The slings and lanyards simultaneously stabilize the mast.

It is understood that the Millennium Dome is a large-scale comprehensive exhibition building covering an area of 73 hectares with a total cost of US$1.25 billion. It includes a series of display and performance venues, shopping malls, restaurants, bars, etc.

Golden Gate Bridge

The Golden Gate Bridge spans north and south, connecting the city of San Francisco and Marin County. The bridge, which took more than four years to build, is one of the most beautiful structures in the world. It is no longer the longest suspension bridge in the world but the most famous.

The massive tower of the Golden Gate Bridge is 227 meters high. Each steel cable weighs 6,412 metric tons and is made of 27,000 steel wires. Construction began in January 1933 and was first completed and opened to traffic in May 1937.

The steel tower stands on the north and south sides of the bridge, with a height of 342 meters, of which the part above the water is 227 meters, equivalent to a 70-story building. Two steel cables connect the top of the tower, each with a diameter of 92.7 centimeters and a weight of 24,500 tons.

The midpoint of the steel cables droops, almost close to the bridge body. The steel cables and the bridge body are connected with thin steel ropes. Data show that the bridge span between the steel towers reaches 1,280 meters, making it one of the rare single-hole long-span suspension bridges built in the world.

Gateway Arch

The Gateway Arch in St. Louis, Missouri, is the tallest freestanding monument in the United States. This gleaming arc-shaped building made of steel rises from the ground, nearly 200 meters high, and its span is also about 200 meters, the same as its height.

According to records, Finnish-American and famous architectural designer Ilo Salinen designed the Gateway Arch in a national design competition in the late 1940s. However, the project did not start until February 1963 and was completed in October 1965. Later, a transportation system was added to the arch, allowing people to climb to a viewing platform at the top of the hook and take in the views. The Gateway Arch, located on the banks of the Mississippi River, is known as the gateway to the West.

Sydney Opera House

The entire Sydney Opera House building covers an area of 1.84 hectares, 183 meters long, 118 meters wide, and 67 meters high, equivalent to the height of a 20-storey building.

Its appearance is three groups of giant shells standing on the base of a cast-in-place reinforced concrete structure that is 186 meters long from north to south and 97 meters wide at its widest point from east to West.

The Opera House is divided into three parts: the Opera Hall, the Concert Hall, and the Benilan Restaurant. The opera hall, concert hall, and lounge stand side by side, built on a giant granite stone base, each composed of four towering large shell tops.

Tokyo Tower

Tokyo Tower is located in Tokyo and was built in 1958. The tower is 333 meters high. The upper part of this tallest independent tower in Japan is equipped with radio transmitting antennas for Tokyo’s 7 TV stations, 21 TV repeaters, and broadcast stations.

There is a two-story observation deck at a height of 100 meters; at an altitude of 250 meters, there is also a unique observation deck. Large floor-to-ceiling glass windows are on all sides of the observatory, and the windows tilt outward. Standing on the observation deck, you can overlook the city of Tokyo and have a panoramic view of the entire city.

World Trade Center

The World Trade Center (1973-September 11, 2001) is located at the southwest end of Manhattan Island, New York, facing the Hudson River to the West. It is one of the landmarks of New York, USA.

The World Trade Center comprises two side-by-side tower skyscrapers, four 7-story office buildings, and a 22-story hotel. It was built from 1962 to 1976. The owner is the Port Authority of New York and New Jersey. The World Trade Center was once the tallest twin towers in the world, a landmark building in New York City, and one of the tallest buildings in the world.

The Twin Towers of the World Trade Center Center adopted an innovative steel frame sleeve structural system design, which connects the peripheral support structure and the central core structure through horizontal floor trusses. This design gives the building extraordinary stability. In addition to bearing the weight of the building, the exterior steel columns also withstand the wind forces acting on the tower. This means the internal support structure only needs to bear its vertical load.

Petronas Twin Towers

Once the tallest skyscraper in the world, the Petronas Twin Towers in Kuala Lumpur remain the tallest twin towers and the fifth tallest building in the world. It is located in the northwest corner of Kuala Lumpur city.

The Petronas Twin Towers in Kuala Lumpur are 452 meters high and have 88 floors above ground. The building, designed by American architect Cesar Pelli, uses many materials, such as stainless steel and glass, on its surface. The Petronas Twin Towers and the neighboring Kuala Lumpur Tower are well-known landmarks and symbols of Kuala Lumpur.

The reinforced concrete frame (core tube) outrigger structure system used in the Twin Towers is a hybrid structure dominated by reinforced concrete structures, using 7,500 tons of steel. The attached circular frame structure next to each main structure is connected to the main body, which can increase the side resistance capacity of the primary system.

Sears Tower

Sears Tower, also called Willis Tower, is a skyscraper in Chicago, Illinois, USA. It was once the tallest building in North America. One World Trade Center broke the record on November 12, 2013. When it was completed, it was called the Sears Tower.

In 2009, London-based insurance brokerage Willis Group agreed to lease a large proportion of the building as an office building and also acquired the building as part of the contract. Naming rights. At 10:00 on July 16, 2009, the official name of the building was officially changed to Willis Group Building.

With 110 floors, the Sears Tower was once the tallest office building in the world. About 16,500 people come to work here every day. There is an observation deck on the 103rd floor for tourists to overlook the city. It is 412 meters above the ground, and four states in the United States can be seen on a clear day.

The building adopts a tube structural system composed of steel frames. The entire building is treated as a cantilevered beam space structure. The further away from the ground, the smaller the shear force. The vibrations caused by wind pressure at the top of the building are also significantly reduced. This dramatically enhances the building’s stiffness and ability to resist lateral forces.

Bird’s Nest

The Bird’s Nest is the main stadium for the 2008 Beijing Olympic Games. The giant stadium design, completed by the 2001 Pritzker Prize winners Herzog and de Meuron in collaboration with Chinese architect Li Xinggang, is shaped like a “nest” that breeds life. Hope for the future. The designers did not do anything superfluous to the National Stadium but left the structure exposed, thus naturally forming the appearance of the building. In July 2007, the British “Times” ranked the ten most prominent and most important construction projects under construction in the world, and the “Bird’s Nest” ranked first at that time. The latest issue of the American “Time” magazine, published on December 24 of the same year, selected the top ten architectural wonders in the world in 2007, and the Bird’s Nest is worthy of being on the list.

The best steel structure building is the Bird’s Nest. The components of its structure support each other to form a network-like framework. The undulating appearance softens the volume of the building and gives it a dramatic and shocking shape.

Steel Building Structures VS Reinforced Concrete

Economy

The steel building structures use advanced design, processing technology, and large-scale production methods to reduce costs significantly. Simultaneously, the simple and rapid installation saves many construction costs and enables enterprises or developers to put it into production more quickly.

Traditional reinforced concrete buildings have a high civil construction cost and long construction periods. The cost is susceptible to unpredictable factors, such as natural disasters, construction in winter and rainy seasons, and rising material prices.

Construction Schedule

The steel structure building can be delivered and installed quickly. The installation is expected to be completed within four or five months after the contract is signed, and it is not affected by winter construction.

The construction speed of traditional reinforced concrete structures is slow, and the construction period can reach 8-10 months or longer.

Carrying capacity

The weight of the steel structure building is usually only equivalent to 1/6 of its design bearing capacity. The importance of components is much lighter than that of reinforced concrete components.

In traditional reinforced concrete buildings, the structure’s weight is often equal to its designed load-bearing capacity, and the prefabricated components are heavy, requiring high-lifting equipment.

Basic cost

Due to the light weight of the steel structure building, the reaction force at the bottom of the column is small, saving many foundation treatment costs.

Traditional reinforced concrete buildings have complicated foundation treatment due to their complex self-weight. Over half of the total structure cost will be used for the foundation in poor soil quality.

Shock resistance

Steel structure buildings have large deformations before destruction, which is easy to detect and avoid. Simultaneously, the steel structure has excellent seismic performance due to the lightweight and the joints’ mechanical properties.

Traditional reinforced concrete buildings are based on the material properties of concrete. Compared with light steel structures, reinforced concrete buildings are more prone to brittle failure, and their seismic performance is significantly lower than steel structure buildings.

Ample space and floor plan

The interior space of the steel structure building is spacious, with a span of up to 60m. It can be expanded and rebuilt relatively quickly, and various industrial pipelines can be flexibly laid out.

The span of traditional reinforced concrete buildings is limited, and prestressing technology must be used to achieve a span of more than 15m. The internal space layout is limited, with many columns and large space waste. After its completion, it is more difficult to persuade its structure. The structural design is more complicated to cooperate with other professions.

Mobility

Bolts can connect the steel structure building, and they can be easily disassembled, transferred, and assembled without much expense, and has muscular mobility. There is no possibility of movement in traditional reinforced concrete buildings.