The service life of steel structure buildings is more than 50 years. The roof and wall panels of prefabricated steel…

Light steel structure workshops are gradually becoming a building choice favored by all walks of life mainly because of their sturdiness, economy, wind resistance, and earthquake resistance. As the advantages of steel structures are gradually recognized, more and more companies are choosing light steel structures for industrial buildings.

Compared with traditional concrete buildings, light steel structure workshops have fast construction speeds, are lightweight but have strong bearing capacity, and have low foundation construction requirements, reducing foundation costs. In addition, light steel structure workshops are prefabricated in factories and assembled on site, which not only reduces construction waste but also reduces construction costs and improves economic benefits.

Light steel structure workshops are mainly used in the industrial field, mainly in the manufacturing industry. Light steel structures can be flexibly laid out according to production process requirements. The large-span, column-free design makes the layout of assembly lines, automated equipment, and large machinery more flexible. The light steel structure has a short construction period, so companies can start production faster, reduce downtime due to site construction agents, and improve overall economic benefits.

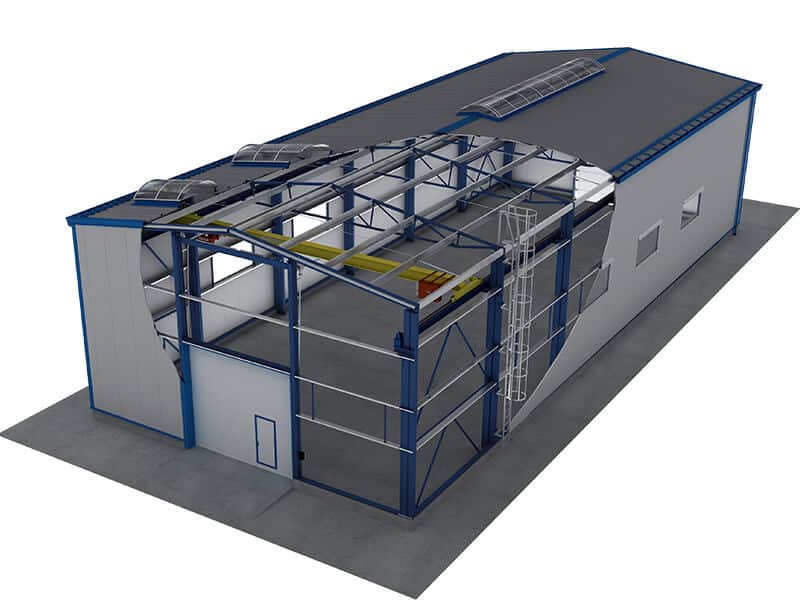

Core components of light steel structure workshop:

Core components of light steel structure workshop:

- Steel column: The main load-bearing element of the light steel structure workshop, which is welded or hot-rolled H-shaped steel, is fixed to the foundation by anchor bolts and bears vertical and horizontal loads.

- Steel beam: The horizontal load-bearing component is connected to the steel column by high-strength bolts to form a stable frame, supporting the roof and hanging equipment and bearing the roof’s load.

- Purlin: This supports the roof and wall panels. Usually, C/Z-shaped steel is used, connected to the steel column and beam by bolts. If the span is large, choose truss purlin or high-frequency welded H-shaped steel.

- Roof and wall: This includes the roof panel, insulation layer, etc., and a color steel plate or sandwich panel can be selected. These provide insulation, rainproofing, and moistureproofing for the workshop.

- Bracing system: This includes column and roof horizontal bracing and improves the workshop’s overall stability. Standard materials are round steel or angle steel.

- Connectors: mainly include high-strength bolts, ordinary bolts, and anchor bolts, which are used to fix and connect various parts of the workshop to ensure the firmness and stability of the overall structure.

- Foundation system: The structure usually adopts an independent foundation or strip foundation designed according to the address conditions. The foundation bears the workshop load and ensures its safety.

Advantages of light steel structure workshop:

1. Short construction period and cost saving

The light steel structure is prefabricated in the factory and assembled on site. Compared with traditional concrete buildings, it reduces labor and equipment costs and significantly shortens construction time.

2. Light structure and reduced foundation investment

The light steel structure has light weight and high strength, which reduces the bearing requirements of the foundation and reduces the construction cost. It is suitable for areas with poor geological conditions.

3. High space utilization and flexible design

The strength and toughness of the steel structure can meet the large-span column-free design and improve the internal space utilization. It can be flexibly laid out according to production needs and can be expanded.

4. Strong earthquake and wind resistance

Light steel structures have good earthquake resistance and are suitable for areas with frequent earthquakes. The steel frame structure with the bracing system can withstand strong winds.

5. Environmental protection, energy saving, and recyclable

Steel structures belong to green buildings, with less construction waste, and 90% of the materials can be recycled and reused, reducing resource waste.

Considerations for designing light steel structure workshops:

1. Clarify the use function and design requirements

The design of light steel structure workshops should consider the production process requirements to ensure that the internal layout of the workshop is reasonable and the use efficiency is maximized.

First, determine the workshop’s height, span, and load-bearing capacity according to the specific production process. Large spans and heights are required for large machinery workshops to accommodate the equipment. However, the height and span can be reduced to save costs for light processing workshops.

Secondly, for workshops with driving, the operating space of the driving track and driving beam should be reserved in advance to ensure smooth operation of the equipment and avoid additional costs caused by later transformation.

Finally, the entrance and exit locations should be reasonably planned to ensure smooth travel of personnel and materials, improve production efficiency, and reduce operating costs.

2. Reasonable selection of structural system

The design of light steel workshops should choose appropriate structural forms according to actual needs. For example, mechanical processing and logistics workshops should choose single-layer structures with large spans, open space, and convenient equipment layout. Multi-layer workshops can be selected for areas with limited land, suitable for industries such as electronics and medicine, saving land and meeting production needs.

Light steel structure workshops usually adopt portal steel frame structures, which are economical and efficient, fast to construct, have a flexible structural design, a simplified construction process, and simple costs, and are ideal design choices.

3. Optimize material selection and improve economy.

Optimizing material types is the key to improving economy and ensuring structural stability. The main structure uses H-shaped steel as steel columns and primary beams, with C/Z-shaped purlins, which reduces material costs while ensuring structural strength. Single-layer corrugated boards are usually used for roofs and walls. Glass wool cotton can be laid if insulation is needed, saving material costs while keeping warm and energy-saving. For structural connections, high-strength bolts or welding must be used to ensure the connection is reliable and improves structural safety.

4. Ensure structural safety and earthquake resistance.

The design of light steel structure workshops needs to be combined with natural conditions such as wind load, snow load, and earthquake at the project site to ensure the safety and earthquake resistance of the structure. Design a reasonable support system. For workshops with cranes, rigid support should be used for column support. Angle steel or H-shaped steel should be used to improve the workshop’s stability under the crane’s operation. The foundation design must meet the requirements of bearing capacity. For seminars with super-large spans, super-high workshops, or multi-story workshops, the foundation must use rigid column feet to ensure that the foundation can support the overall structure.

5. Meets ventilation, lighting, and energy-saving requirements

The light steel workshop reasonably arranges ventilation windows, exhaust fans, and light strips to ensure internal air circulation and natural lighting, improve the air quality inside the workshop, reduce lighting requirements, and improve the production environment. In addition, thermal insulation cotton should be laid on the roof and walls to block external heat from entering the workshop, keep it warm, and reduce energy consumption. Solar panels can also be laid on the roof to generate electricity using photovoltaics to meet the daily electricity needs of the workshop and reduce operating costs.

The differences between light steel structure and heavy steel structure

1. Materials

Light steel structures: Light steel structures use lighter steel, such as H-shaped steel, round steel, angle steel, and C/Z-shaped steel.

Heavy steel structure: Heavy steel structures use steel with large cross-sections and thickness, such as box-shaped or lattice columns. Because they are heavy, the foundation design requirements are high.

2. Carrying capacity

Light steel structure: Medium-sized buildings with low bearing capacity are suitable for loads below medium. For example, factories, warehouses, and buildings that can meet conventional production and storage requirements.

Heavy steel structures: Heavy cranes or buildings with large bearing capacity, such as heavy machinery factories or high-rise buildings, have relatively high requirements for strength and stability.

3. Foundation design

Light steel structure: The structure is light in weight, and the foundation design requirements are relatively low. The column base is mostly hinged.

Heavy steel structure: The structure is heavy and has high bearing capacity, so the foundation bearing capacity is strong. The design requirements for the foundation are relatively complex, the column base is rigidly connected, and the foundation construction cost is high.

4. Cost

Light steel structure: This type of structure suits small and medium-sized factories and warehouses with limited budgets. The overall cost is low, and the construction speed is fast.

Heavy steel structure: The steel is thicker and heavier, so the processing and transportation costs are higher. The construction is complex, and the cycle is long. The construction process requires heavy equipment, and the construction cost is high.

Conclusion:

Light steel structure workshops are suitable for industrial manufacturing. According to different production process requirements, the assembly line can be flexibly arranged, and the automation design can be realized. Compared with traditional concrete structures, the construction cycle is short, and enterprises can start production faster, improving the overall economic benefits.

In general, the advantages of light steel structure workshops make them ideal for industrial buildings. For enterprises considering building workshops, understanding their design characteristics and cooperating with professional manufacturers will help the project be smoothly implemented and put into production as soon as possible.