The service life of steel structure buildings is more than 50 years. The roof and wall panels of prefabricated steel…

In today’s fast-evolving industrial landscape, steel structure factory buildings stand as a preferred architectural solution—one that balances durability, efficiency, and spatial adaptability. Unlike conventional concrete structures, steel-framed factories offer faster construction timelines, optimized material use, and greater design flexibility. From heavy machinery plants to high-precision electronics facilities, steel buildings serve a broad spectrum of operational requirements while supporting future scalability.

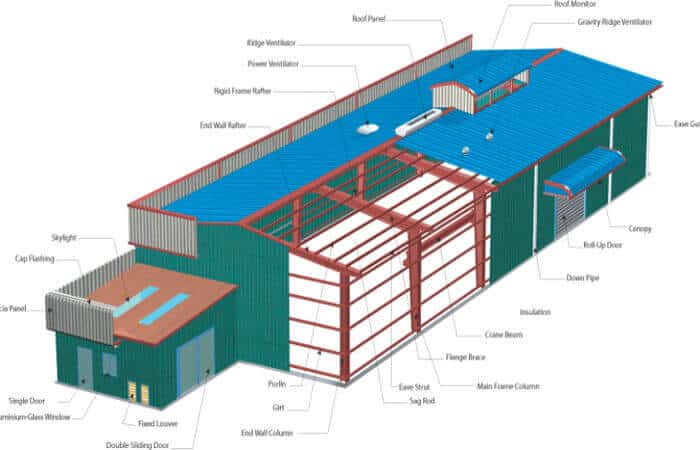

A steel structure factory building includes the following :

A steel factory building is typically composed of prefabricated modules that interconnect to form a high-performance envelope. The primary elements include:

- Main Load-Bearing Frame: Constructed from welded H-section steel columns and beams, the frame is engineered to resist both axial and lateral forces, ensuring stability under dynamic industrial loads.

- Secondary Framing: C- or Z-shaped steel purlins and girts provide intermediate support for roofing and wall panels, distributing loads across the frame.

- Cladding System: Roofing and wall panels are typically manufactured from corrugated steel sheets or composite sandwich panels filled with polyurethane, rock wool, or glass wool insulation—enhancing thermal regulation and fire resistance.

- Connectors and Fasteners: High-strength bolts, self-tapping screws, and sealants ensure structural integrity and airtight performance, while embedded anchor bolts secure the frame to its reinforced concrete foundation.

How to design a steel structure factory building

Effective factory design begins with a clear understanding of spatial and functional requirements. Several core parameters influence the performance and cost-efficiency of a steel structure:

- Span Width: Standard spans range from 6 to 24 meters. For specialized applications, spans up to 36 meters are achievable but require proportionally higher material input and engineering precision.

- Column Grid Spacing: Commonly set between 6 to 9 meters, column spacing directly affects foundation complexity and roof member sizing. A wider grid reduces the total number of supports but increases the dimensions—and cost—of purlins and crane beams.

- Vertical Clearance: Varies significantly by industry, as illustrated below:

| Industry Sector | Minimum Clear Height |

|---|---|

| Printing & Packaging | ≥12 meters |

| Mechanical Equipment | ≥10 meters |

| Electronics & Furniture | ≥8 meters |

| General Manufacturing | ≥6 meters |

- Daylighting & Airflow: Skylights, translucent panels, and ridge-mounted ventilators are commonly integrated to reduce energy consumption and improve indoor environmental quality.

Design Insight: Combining roof daylight panels with side-mounted windows reduces reliance on artificial lighting while enhancing indoor comfort.

Functional Classification of Factory Layouts

Steel factory buildings can be categorized based on layout logic and industrial function:

By Number of Floors

- Single-Story Structures: Common in heavy industry, these accommodate overhead cranes, large machinery, and unimpeded workflow.

- Multi-Story Designs: Ideal for sectors such as pharmaceuticals, electronics, and textiles, where space efficiency and compartmentalized processes are crucial.

- Hybrid Configurations: Incorporate both low-rise and multi-level sections, enabling complex operations within a unified structure.

By Span and Configuration

- Small-Span Buildings (≤12m): Often applied in low-load applications, such as warehousing or light assembly.

- Large-Span Structures (>30m): Suitable for aviation, shipbuilding, and large fabrication facilities.

- Multi-Span Layouts: Characterized by parallel bays sharing intermediate supports—optimal for scalable production zones.

- T- or Cross-Shaped Designs: Facilitate intersecting workflows, often found in power plants and chemical production lines.

By Operational Function

- Main Production Workshops: Centralized for fabrication, assembly, or manufacturing.

- Auxiliary Facilities: Support areas for maintenance, tool management, or material prep.

- Storage Zones: Dedicated warehouse segments for materials and finished goods.

- Infrastructure Compartments: Host mechanical systems, power distribution, and vehicle logistics.

Comparative Overview of Factory Structures

| Structure Type | Key Attributes | Suitable Applications |

|---|---|---|

| Brick-Wood | Cost-efficient, limited durability | Temporary workshops, rural uses |

| Brick-Concrete | Fireproof, thermally insulated | Mid-rise buildings, older factory typologies |

| Reinforced Concrete | Strong but heavy and slow to build | Public facilities, industrial towers |

| Steel Structure | Lightweight, modular, long-span | Modern factories, logistics, and warehousing |

Performance Advantages of Steel Structures

Steel-framed factories deliver significant advantages over traditional concrete buildings, both structurally and economically:

| Feature | Steel Structure | Concrete Structure |

|---|---|---|

| Construction Speed | Prefabricated, rapid assembly | Time-intensive, labor-heavy |

| Dead Load | Up to 50% lighter | Heavy |

| Span Capacity | Wide, unobstructed spaces | Limited without large beams |

| Environmental Impact | Fully recyclable, clean construction | Higher carbon footprint |

| Space Utilization | 4–8% higher usable area | Bulkier structure |

| Seismic Resistance | High ductility and resilience | Brittle under stress |

Additionally, steel buildings offer modularity for future expansion, easy retrofitting, and more efficient land use.

Applications Across Industrial Sectors

Steel factory buildings are widely adaptable across various industries:

- Heavy Manufacturing: Large, unobstructed spaces suitable for cranes, presses, and heavy production lines.

- Electronics & Pharmaceuticals: Require temperature-controlled, often multi-floor environments with cleanroom potential.

- Food & Chemical Processing: Demanding strict compliance with fire protection, air circulation, and waste management.

- Textile & Light Industry: Efficient material flow, often vertical layouts with integrated freight elevators.

- Power & Utility Plants: High-clearance halls for transformers, turbines, and power systems.

- Custom Engineering Facilities: Tailored designs for prototyping, research, and specialty production.

Sustainability, Compliance, and Future Resilience

Steel structures are naturally aligned with the principles of sustainable development and regulatory compliance:

- Material Sustainability: Structural steel is recyclable with minimal performance loss.

- Construction Efficiency: Off-site fabrication minimizes construction time and environmental disruption.

- Code Adaptability: Easily engineered to meet seismic, fire, and energy efficiency standards.

- Long-Term Value: Lower maintenance costs, adaptable infrastructure, and greater resale potential.

Frequently Asked Questions about Steel Structure Factory Buildings

What is the typical construction timeline for a steel factory building?

The construction period generally ranges from four to eight weeks, depending on the building’s size and level of complexity. This efficiency is largely due to the use of off-site prefabricated components, which significantly reduce on-site labor and weather-related delays.

Are steel factory buildings capable of supporting cranes or mezzanine levels?

Absolutely. Modern steel structures are frequently engineered to accommodate overhead crane systems, suspended walkways, and multi-level interior platforms. These design features are essential for facilities requiring vertical integration or heavy material handling.

How environmentally sustainable are steel structure factory buildings?

Steel buildings are among the most sustainable construction options available today. The structural steel used is fully recyclable, while the construction process generates minimal site waste. When combined with insulated panel systems, these buildings also offer excellent thermal efficiency, reducing operational energy consumption over time.

What is the expected service life of a steel factory building?

With proper design and routine maintenance, steel factory buildings can reliably serve for 50 years or more. Their resistance to corrosion, seismic activity, and environmental stress contributes to exceptional structural longevity in industrial environments.

Conclusion: Why Steel Is the Intelligent Choice for Modern Industry

Investing in a steel structure factory building means securing more than just a production space—it means building with foresight. Steel construction enables faster project delivery, optimal space utilization, and long-term operational flexibility. As industries continue to evolve, so too must their infrastructure.

Whether you’re launching a new production facility or modernizing outdated premises, steel structures offer a future-proof solution engineered for performance, sustainability, and growth.