The service life of steel structure buildings is more than 50 years. The roof and wall panels of prefabricated steel…

What is a Steel Frame Building

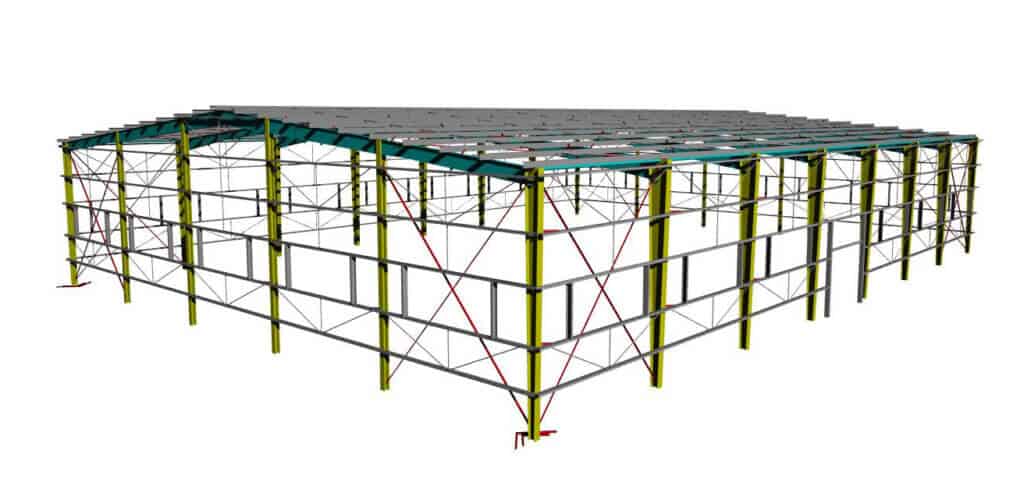

A steel frame building refers to a structural system composed of interconnected steel columns and beams, forming a rigid skeletal framework capable of resisting both vertical and lateral forces. Typically constructed using welded or hot-rolled H-section steel members, these structures rely on high-strength bolted or welded connections. Their superior strength-to-weight ratio and design flexibility make them a preferred solution in industrial architecture—particularly for warehouses, manufacturing plants, workshops, and logistics centers.

Core Structural Components

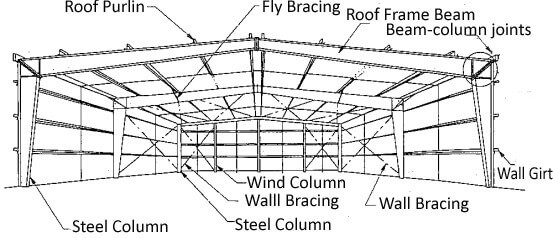

Primary Frame: The structural backbone consists of H-shaped steel columns and beams that bear vertical and horizontal loads.

Secondary Elements: C- and Z-section steels serve as purlins and wall girts, supporting roofing and wall cladding systems.

Enclosure Systems: Corrugated steel panels are used for both roof and wall cladding due to their durability and ease of installation.

Thermal Insulation: Materials such as glass wool, rock wool, rigid polyurethane, and polystyrene foam enhance energy efficiency and occupant comfort.

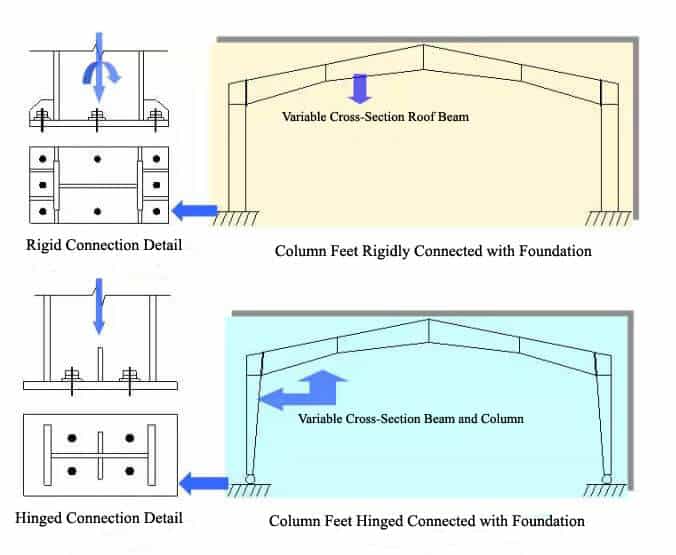

Characteristics of Portal Frame Design

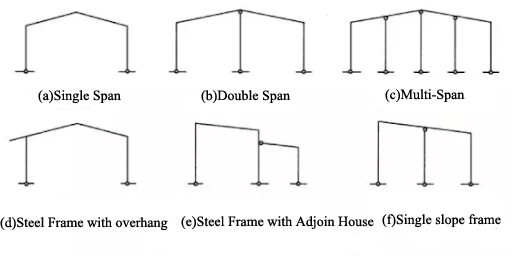

Steel portal frames utilize moment-resisting connections between beams and columns, providing structural stability across wide spans. These systems are adaptable to a variety of building configurations:

- Span Range: Typically between 9 and 36 meters.

- Building Height: Commonly ranges from 4.5 to 9 meters, depending on clearance requirements.

- Frame Spacing: Standard intervals include 6 m, 7.5 m, and 9 m, optimized based on load conditions and architectural function.

Roof profiles vary by project needs and may include single-ridge single-slope, gable-roof double-slope, or multi-ridge forms. The slope of the roof typically ranges from 1:20 to 1:8, selected based on factors such as precipitation, drainage requirements, and snow or wind loads.

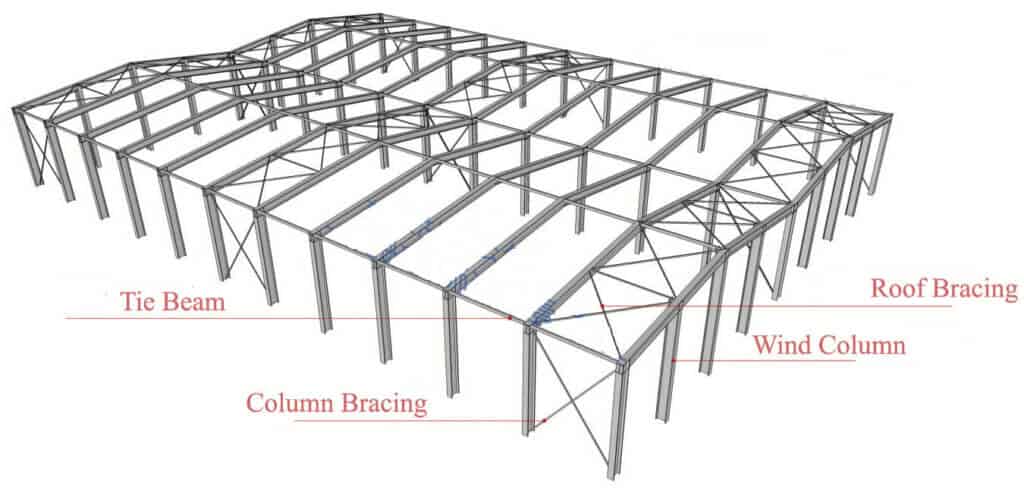

Structural Layout and Bracing Systems

Purlins and Wall Girts

The spacing of roof purlins is determined by factors such as skylight locations, daylight panel layout, and panel dimensions. Wall girts are arranged to accommodate doors, windows, and canopy elements, ensuring structural compatibility with enclosure components.

Bracing Configuration

Bracings are fundamental to maintaining lateral stability. Roof and wall bracing systems are arranged to form a geometrically stable frame. In buildings equipped with cranes or those exceeding 60 meters in width, additional lateral supports must be introduced.

Tie Beams and Stiffeners

Longitudinal tie beams enhance rigidity along the building’s length. In certain configurations, purlins can act as stiffening members if they meet the required load and deformation criteria.

Load Considerations and Design Combinations

Steel frame buildings must address a combination of permanent and variable loads, including:

- Dead Loads: Self-weight of structural members and attached architectural elements.

- Live Loads: Roof traffic, snow accumulation, crane operations, wind pressures, and seismic forces.

Load combinations adhere to the standards set forth in GB 50009-2012 and CECS 102:2002 (2012 edition), including:

- Snow and live loads are not combined; the greater value governs.

- Wind and seismic forces are considered separately.

- Multiple crane loads must comply with national design protocols.

Design and Engineering Considerations

When designing portal steel structures, engineers must address several critical factors:

- Ensure components can resist deformation during transport and erection.

- Integrate bracing and edge stiffeners into the global load path.

- Apply appropriate corrosion protection measures, including coatings and galvanization.

- Avoid over-lightweighting of roof systems, which may lead to negative pressure-induced uplift under wind action.

Fabrication Best Practices

Post-weld treatments, including shot blasting and consistent coating, are critical to long-term durability.

Steel surfaces must be free of rust and contaminants prior to cutting or welding.

Bolt holes must meet precision standards; misaligned holes should be corrected via re-welding, not plugging.

Welding rods, fluxes, and wires must be dry and clean before use.

Installation Process

Temporary supports or stiffeners may be required during phased erection to ensure safety and alignment.

Pre-assembly checks must confirm dimensional accuracy and the absence of deformation.

Installation should follow a sequential method that forms a stable spatial unit early in the process.

High-strength bolts must be tightened following specified torque patterns, often starting from the center outward.

Advantages Over Concrete Structures

Layout Flexibility: Unlike concrete, steel permits customizable column spacing, enhancing space utilization and reducing material waste.

Lightweight: Steel structures weigh only 1/20 to 1/30 that of concrete systems, reducing foundation costs.

Rapid Construction: Off-site prefabrication and modular assembly minimize on-site labor and construction time.

Project Highlight: Steel Frame Warehouse in Guam (2022)

In 2022, Havit Steel completed a 2,875 m² single-span warehouse project in Guam. Featuring a clear span of 25 meters and an eave height of 7.5 meters, the building was designed with high wind and seismic resilience in mind—critical in typhoon-prone regions. Glass wool insulation ensured thermal efficiency, while the robust structural framework offered long-term durability in a demanding environment.

Read more: Steel Warehouse Project in Guam.

Frequently Asked Questions

What is a steel frame building?

A steel frame building is a structure made of interlinked steel beams and columns designed to carry vertical and lateral forces through rigid connections.

What are the advantages of steel over concrete?

Steel construction offers significantly lighter weight, faster installation timelines, and more flexible spatial layouts compared to conventional concrete systems.

How long does it take to build a steel frame structure?

Thanks to off-site prefabrication, most steel frame buildings can be completed in a matter of weeks, depending on project scale and site conditions.

Are steel frame buildings suitable for industrial use?

Absolutely. Their strength, open-span capability, and modularity make them ideal for industrial applications like warehouses, factories, and logistics centers.

What design codes apply in China?

Steel frame buildings in China typically comply with GB50009-2012 (Load Design Code) and CECS102:2002 (Technical Code for Portal Steel Frame Structures).