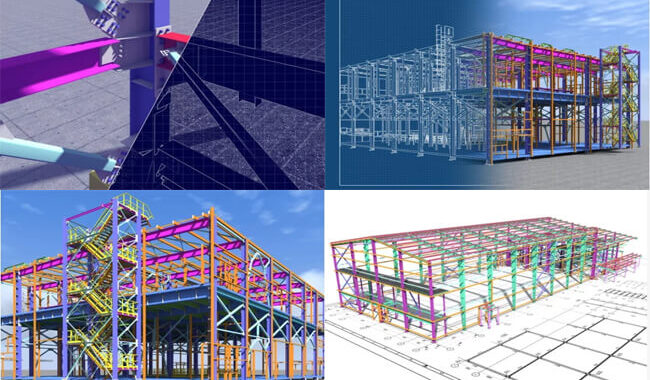

What are steel structure fabrication drawings? Steel structure fabrication drawings, also known as processing details, refer to technical documents that…

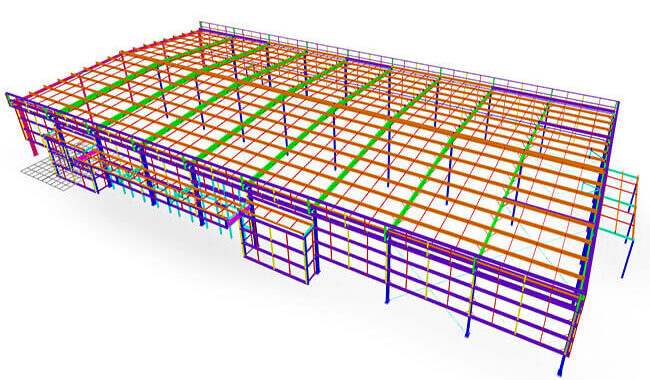

Steel structures are an indispensable part of modern architecture and are widely used in various construction projects due to their unique strength, flexibility, and adaptability. Steel structure systems include plane load-bearing structures, spatial force structures, and multi-story building structures.

Steel structure systems: characteristics and applications

1. Steel structure system: Plane load-bearing structure system

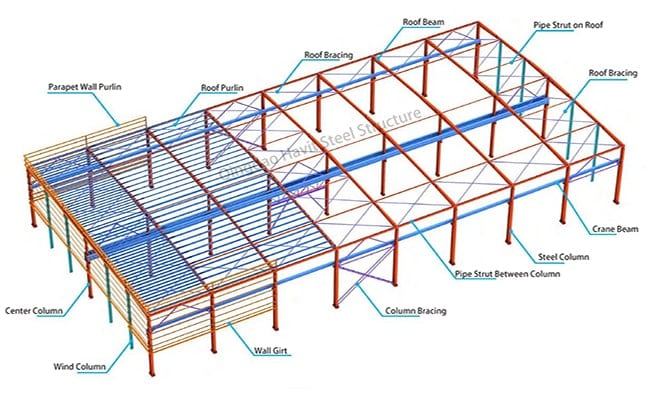

The plane structure system consists of the load-bearing system and additional components. The load-bearing system comprises a series of parallel plane structures, which bear the vertical and lateral horizontal loads in the structure’s plane and transmit them to the foundation.

Additional components are composed of longitudinal components and supports, which connect the various plane structures into a whole and bear the longitudinal horizontal force outside the structure’s plane.

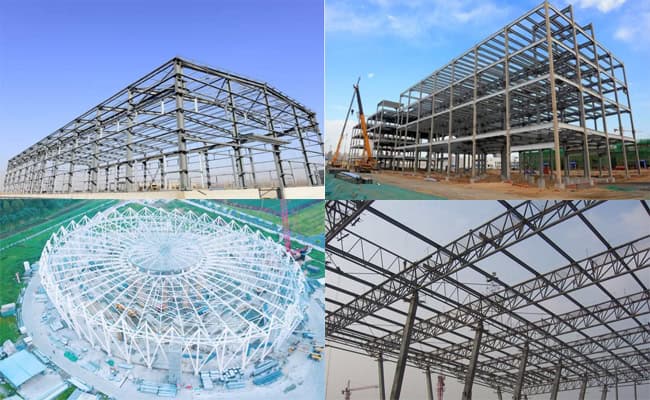

The frame steel structure system is a plane load-bearing structure system that has been widely used recently. In addition to factory buildings, there are commercial buildings (such as supermarkets, etc.), car showrooms, gymnasiums, etc.

Steel structure system: Spatial force structure system

The spatial force structure system is divided into mesh inter-chamber structure, flexible structure, etc.

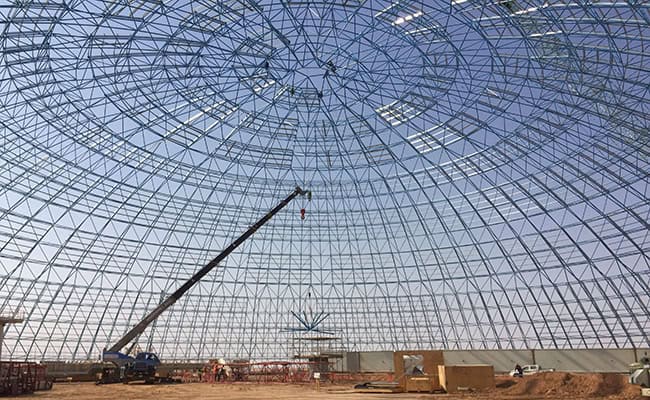

(1) The grid structure of rigid space structure includes grid structure, grid shell structure, and truss structure.

The grid structure is a kind of space grid structure. It is composed of roughly the same grid or smaller units. Due to its excellent binding performance, good economy, safety, and applicability, grid structure is widely used in my country, especially in large public buildings and industrial factory roofs.

The grid shell structure belongs to the curved grid structure. There are only two types: single-layer and double-layer. It is a shell that is mainly subjected to the internal force of the membrane. It has the characteristics of a simple rod structure and the reasonable force of a thin shell structure. Therefore, it is a large-span and ultra-large-span space structure with large capacity, good rigidity, fewer materials, single rods, convenient installation, broad application, and development prospects.

(2) Flexible space structures include cable suspension structure, chord support structure, and cable membrane structure

1) Cable suspension structure

The cable suspension structure resists external loads through the axial stretching of the cable. It is a space steel structure system formed by tensile steel cables as the primary bearing components, arranged according to a specific rule, and suspended on edge components or supporting structures.

The material of the steel cable is a high-strength steel wire strand, rope, or bundle.

The tensile strength of the steel cable can be fully utilized to reduce the deadweight of the structure significantly.

The edge member or supporting structure is used to anchor the steel cable and bear the tension of the suspension cable. A ring beam, arch, truss, etc., or a flexible cable can be used as the edge member.

2) Suspension structure

The suspension structure (beam-string and suspension dome) comprises a lower chord, an upper beam, and a vertical web member.

Cable-bar and beam steel structure system: by tensioning the lower chord, the axial force of the web member causes the upper chord beam to produce internal force and displacement corresponding to the external load, which plays an unloading role.

3) Cable-membrane structure

The cable-membrane structure is a new building structure developed in the mid-20th century. It is a spatial form formed by various high-strength film materials and strengthening members (such as steel frames, columns, or cables) in a certain way to generate a specific pre-tension stress inside, as a covering structure and a spatial structure that can withstand a particular external load.

3. Steel Structure system: Multi-story building structure system

The multi-story structure system mainly consists of a frame, a frame-support system, a frame-inner tube system, a frame-inner tube system with arm trusses, a tube-in-tube system, and a bundled tube system.

The frame steel structure is a commonly used steel structure form, primarily used in large-span public buildings, industrial plants, and some buildings and structures with special requirements for building space, building shape, and building function, such as theaters, shopping malls, gymnasiums, exhibition halls, shipyards, aircraft factories, parking garages, warehouses, industrial workshops, power plant boiler frames, etc.

It has become increasingly widely used in high-rise and super-high-rise buildings. For example, recently, the steel structure frame residential system has become increasingly valued by people.

Frame structures can generally be divided into single-layer single-span, single-layer multi-span, and multi-layer multi-span structures to meet the needs of different building shapes and functions.

According to the structure’s different lateral force resistance systems, the steel structure frame can be divided into a pure frame, a central braced frame, an eccentrically braced frame, and a frame tube.

Which buildings are suitable for steel structures?

Steel structure systems are widely used in various construction engineering structures. It is particularly suitable for large factories, stadiums, super high-rise buildings, and buildings with high strength, large span, and super heavyweight.

1. High-rise building

Since steel components have a significant bearing capacity, the component cross-section is smaller when carrying the same load, giving the building a larger use space. Therefore, commercial buildings, hotels, apartments, and other multi-story, high-rise, and super-high-rise buildings increasingly use steel structures. Relevant data show that compared with concrete structures, steel structures using BH steel supports can reduce their weight by 20%- 30% and increase the usable area by 5%- 8%.

Steel structures are generally used in workshops suitable for heavy loads and production, such as open-hearth workshops, steel rolling workshops, smelting workshops in metallurgical industrial plants, forging workshops in heavy machinery plants, and hull assembly workshops in shipyards.

2. Light steel structures

The main load-bearing components are combined with light cold-bent thin-walled steel, light-welded high-frequency welded steel, thin steel plates, thin-walled steel pipes, and light hot-rolled steel splicing and welding. Many single-layer or multi-layer buildings use lightweight enclosure isolation materials.

3. Bridge structures

Steel structures are used for medium-span cable-stayed bridges and suspension bridges, such as the Nanpu Bridge in Shanghai and the Jiujiang Bridge, for railway dual-use double-deck bridges. Since steel structures are strong and relatively light, some structures that often need to be disassembled and assembled, such as prefabricated houses, hydraulic gates, ship lifts, bridge cranes, various tower cranes, gantry cranes, cable cranes, etc., all use steel structures.

4. Large-span steel structures

Using steel structures in large-span buildings can often better reflect and enhance the image of the building itself. For example, the multifunctional gymnasium of the new campus of Guangxi Construction Vocational and Technical College and Guilin North Railway Station, these buildings use steel structures.