A steel frame is a structure made of steel, usually connected by welding, bolting, or riveting steel beams, columns, bracing,…

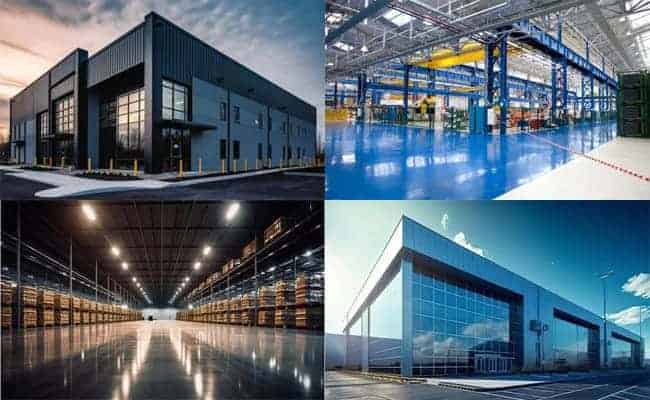

Industrial buildings refer to buildings used for various production activities and storage.

According to the classification of industrial buildings, it includes:

Production category: including production workshops of various industrial enterprises.

Auxiliary categories: including machine repair, tool, and model workshops.

Power category: including power stations, gas stations, compressed air stations, substations, and boiler rooms.

Warehousing: including raw materials and finished products, semi-finished products warehouses, etc.

Characteristics of industrial buildings

- Meet the requirements of the production process.

- There is a larger area and space inside.

- The structure and structure are complex and require high technical requirements.

- Production must be closely integrated.

- Industrial buildings with different production processes have other characteristics.

- Lighting, ventilation, roof drainage, and structural processing are more complicated.

Types of industrial buildings:

Industrial Factory Building

Industrial factory buildings refer to facilities directly used for production or supporting production. In addition to the production workshops, factory buildings include their ancillary buildings.

Scope of use of industrial factory buildings:

The main production plant refers to the building completing a complete production process procedure.

Auxiliary production plant refers to the part of the plant that assists the main production plant.

Power plant: It is a place that provides the energy required for the production process to the main production plant.

Warehouses and storage rooms

Warehouse is the general term for buildings and places where goods are stored and kept. The concept of warehouse can be understood as facilities such as places and structures used to store goods, including production materials, tools, or other property, as well as their quantity and value. It also includes land used to prevent the reduction or damage of goods. Or water surface. From the perspective of social and economic activities, the production and circulation fields are inseparable from warehouses.

Cold Storage

Cold storage is a warehouse that uses cooling facilities to create suitable humidity and low-temperature conditions—also known as cold storage, freezer, and fresh-keeping warehouse. Cold storage is a place for processing and storing products. It can eliminate the influence of climate, extend the storage period of various products, and regulate market supply.

Cold storage is a building that uses artificial refrigeration to bring a fixed space to a specified temperature to facilitate the storage of items.

Cold storage is mainly used for constant temperature storage of food, dairy products, meat, aquatic products, poultry, fruits and vegetables, cold drinks, flowers, green plants, tea, medicines, chemical raw materials, electronic instruments, etc.

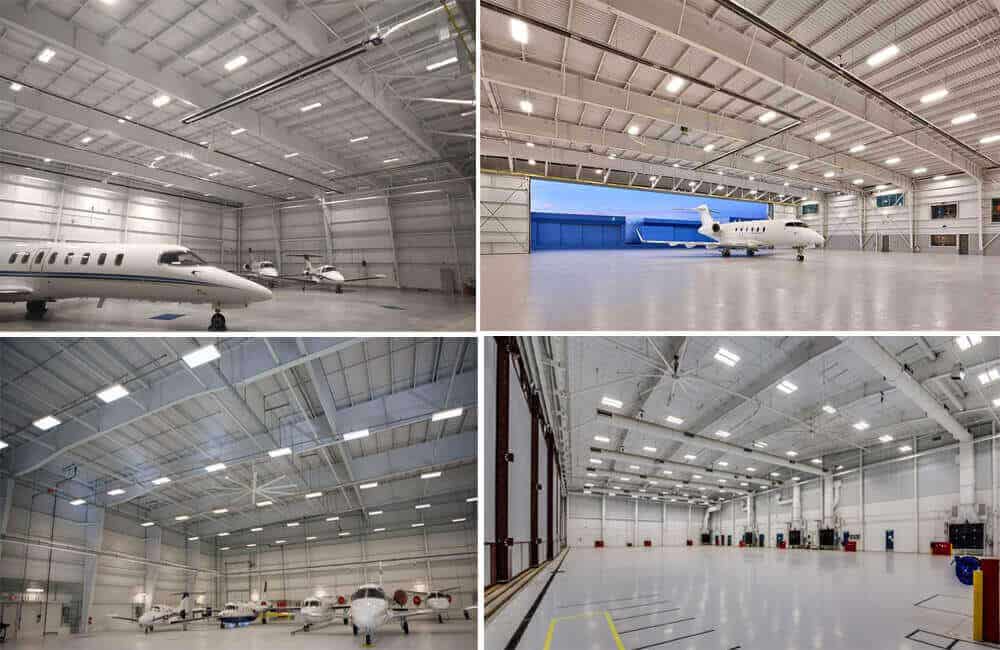

Hangar

An aircraft hangar is a long-span single-story building for maintaining aircraft. It is the main building in the aircraft maintenance area.

The hangar is a unique building form that develops with the size of the aircraft.

Due to the functional requirements, it has the following structural characteristics:

- Large horizontal span and high indoor clearance. The span of a large single-stand hangar is generally 60 to 90 meters. The span of a sizeable two-stand hangar is usually required to be greater than 150 meters. The hangar depth is generally 70 to 90 meters, and the indoor clear height is generally 17 to 26 meters.

- One side of the door must be open due to the need for aircraft access. The roof is mainly supported by columns on three sides, and the structural layout is asymmetrical.

- Various suspended mobile maintenance equipment is installed on the roof, which requires high deformation resistance. At the same time, the roof structure must also provide an upper fulcrum for the movable hangar door.

- The hangar door is heavy, requires easy opening, and has a unique structure.

- The total height of the building is strictly limited by airport clearance requirements, which usually require the highest point of the building not to exceed 45 meters.

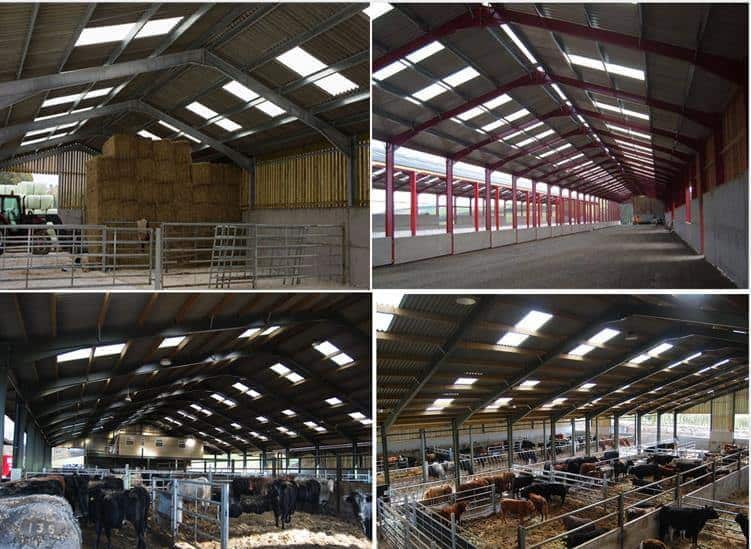

Livestock buildings

Agricultural production buildings for raising livestock and poultry. Including livestock and poultry house buildings, auxiliary buildings, etc. The facilities are designed according to different animal species to provide comfortable living conditions and breeding environments. Livestock buildings include stables, pig houses, chicken houses, cow houses, and sheep houses.

Industrial building design

1. Industrial building design for Fireproof

Steel structures are currently widely used in industrial building structures. Compared with concrete structures, they have high strength and good plasticity advantages. However, steel has strong thermal conductivity, and temperature has a more significant impact on steel. The tensile strength of steel above 100°C will gradually decrease. Decrease, the plasticity will increase, and the plasticity will also reduce when the temperature reaches 250°C. The steel will directly break when the temperature reaches 500°C. Therefore, steel’s fire prevention and heat insulation capabilities are poorer than concrete structures, making industrial plants with steel structures safer. The hidden danger is more significant.

The optimization of fire protection design

The fire protection grade should first be determined based on the construction process drawings and the production type’s demand for fire protection and heat insulation. The national fire protection regulations should be strictly followed during design. The selection of materials should also meet the quality and fire protection grade requirements, and fire protection should be applied to the steel. Coating. During fire protection design, the layout design of industrial buildings should also be optimized, and fire protection and insulation facilities, safe evacuation passages, and fire staircases should be scientifically arranged. Heat-resistant protection should be carried out for thermal insulation design, such as protecting steel materials within the radiation range near heating furnaces in metallurgical industrial plants.

2. Seismic design

The design of the steel structure in the transverse system is the most critical link in the structural design of industrial buildings. It is necessary to comprehensively consider the mechanical performance of each accessory of the steel structure and control various adverse effects to a minimum according to the changing rules of the transverse system to give full play to the steel structure.

When analyzing the impact of earthquake factors on industrial buildings, the effect of the external environment on the building should be fully considered, the structural frame should be selected based on the essential requirements of the steel structure work, and the design of the nodes should be done well to ensure part of the connection steel construction. Tensile resistance and strength, thereby improving the earthquake resistance of industrial buildings.

3. Anti-corrosion design

Steel structures are prone to oxidation and corrosion in natural environments, especially in humid climates. The degree of oxidation and erosion of steel structures is more serious, causing stress concentration problems in the steel structure’s force and shortening the steel structure’s service life.

Currently, anti-corrosion and anti-rust coatings are mainly used to isolate the corrosion factors in the environment from the steel structure to prevent corrosion of steel.

When carrying out anti-corrosion design for steel structures, the background of the industrial plant should be fully considered for reasonable anti-corrosion design. The anti-corrosion and anti-rust coating thickness should be reasonably controlled based on the environment where the steel is located.

4. Facade design

When optimizing the structural design of industrial buildings, aesthetics, such as lines, scale, and color, should be improved while ensuring economic applicability.

The horizontal and vertical structure of the lines is determined by the facade height of the industrial factory, and the type of building determines the scale.

For example, if an industrial factory used for heavy industrial production is large in scale, aesthetics should be pursued while satisfying the craftsmanship. In addition, eye-catching signs should be designed in industrial plants’ hazardous areas to increase production personnel’s safety awareness.

5. Energy-saving and environmentally friendly design

When energy-saving buildings are widely used, the energy-saving of industrial buildings is getting more and more attention. With the development of science and technology, the energy-saving level of industrial facilities will increase.

For example, Germany’s current building energy-saving code, EnEv2007, uses special building energy-saving calculation software to input energy consumption and supplementary renewable energy and conduct unified overall planning and recording of buildings to achieve the purpose of intelligent energy-saving control.

However, this method needs to be based on accumulating enough basic parameters to reduce the error of the calculation software algorithm. It must also unify the energy-saving certificate system and achieve unified algorithm standards.

6. Other designs

For the lighting, heating, ventilation, air conditioning, water supply, and drainage systems in industrial buildings, the physical techniques of architectural design can be used to design the natural lighting area rationally, the laying of insulation and reflective layers, and the layout of cross-ventilation ducts and water systems. Diverse methods, such as recycling and secondary use, are used to realize the current energy-saving concept.