As the primary building material for steel structure industrial buildings, light steel structures directly affect the stability of the main…

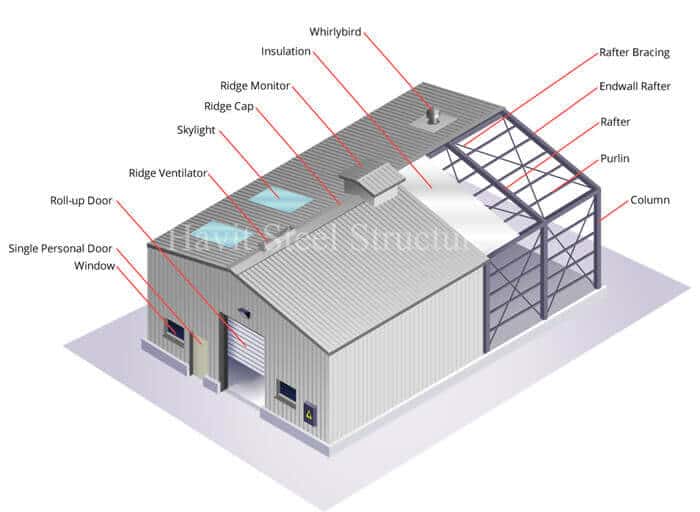

Prefab steel structure warehouse building comprises beams, columns, trusses, purlins, and more. These components are connected using welding or bolting technology. The parts are prefabricated in the factory and then transported to the construction site, assembled to form a complete building structure.

The Structure of Prefab Steel Structure Warehouse?

There are two primary structural forms of prefab steel structure warehouse: metal rigid frame structure and truss structure. The roof and walls of the prefab steel structure warehouse building are clad in corrugated metal panels or sandwich panels that are insulated with various materials to maintain temperature and humidity levels.

Prefabricated steel structure warehouses are widely used in logistics, warehousing, industrial production, and other fields due to their superior characteristics and suitability for storage needs of various scales.

The details of the Prefab Steel Structure Warehouse Building:

Design and Planning

To construct a steel structure warehouse, a comprehensive design plan must be established in advance, which should take into account the intended use of the warehouse, as well as its location and size. Once the building’s size has been determined, deciding whether a single-span or multi-span design or a single-story or multi-story layout is best suited to the intended purpose is essential. Typically, the steel frame width ranges between 18-24 meters. The height of the warehouse should be determined based on the required internal space or storage capacity of the goods, with a standard height of 6 meters for most warehouses. In cases where a crane is intended to be used, the warehouse building’s height must be designed according to the crane’s maximum lifting height.

Building size:

The dimensions of the steel warehouse building will vary depending on the country. Generally, the construction area will take up around 70% of the total land area. For instance, if the land area is 5000 square meters, the building area would be approximately 3,500 square meters, which includes warehouses and office buildings. For more information, please refer to the local building regulations.

Crane runway system:

Do you need to install overhead cranes in your warehouse?

If a crane is required, please consider the height of the warehouse according to the specific lifting height.

Base

A local civil engineering company typically performs the construction of the foundation for a steel structure warehouse. The steel structure manufacturer provides the necessary information, including the bending moment, shear force, and axial force of the steel columns, to the civil construction contractor, who then performs the foundation calculation and construction. Since the construction of steel structure buildings is based on a unified structural unit, natural or artificial foundations are not suitable, and a proper foundation must be constructed to ensure the structural integrity and stability of the building.

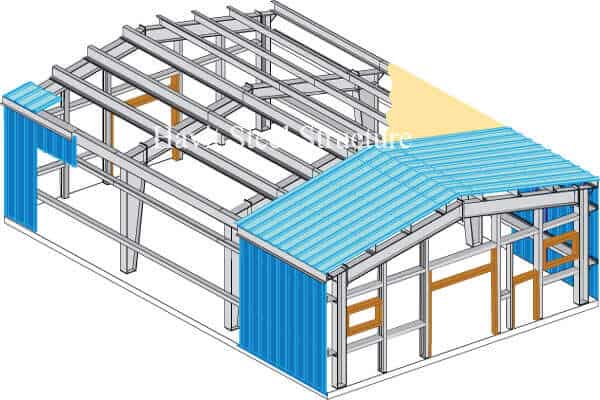

Steel frame

The steel frame is an essential component of a warehouse building, serving as the primary load-bearing structure. The portal steel frame and truss structure are the most commonly used steel frames. The steel frame typically includes steel columns, roof beams, and roof trusses, with the addition of floor beams in multi-layer or mezzanine. In addition to the primary structure, the warehouse building requires a secondary structure comprising braces, tie rods, purlins, wall beams, and stays. The combination of primary and secondary structures results in a complete force-bearing structure capable of withstanding the weight of goods stored within the warehouse building.

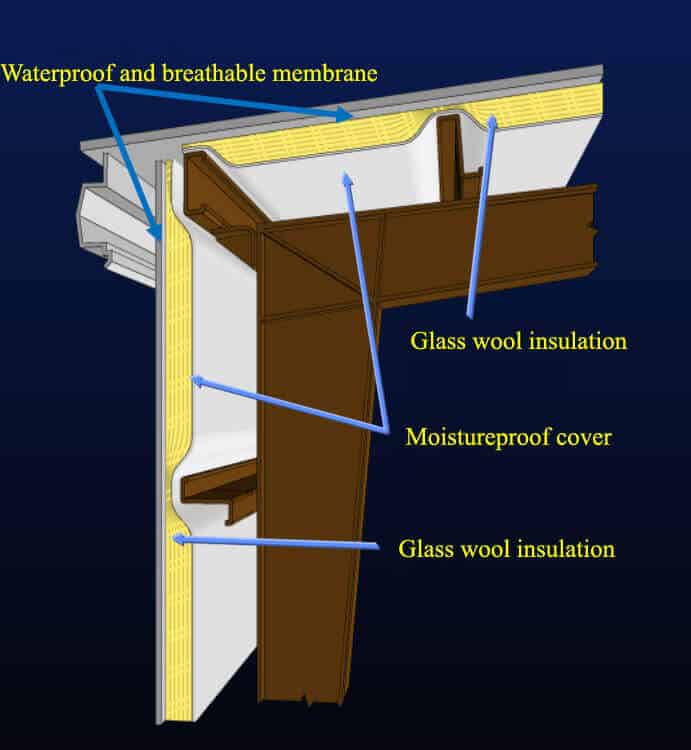

Roof and wall

Roofs and walls are essential in protecting a building from the outside environment. Roofs and walls are usually made of corrugated color steel sheets. Color steel sheets have the advantages of being lightweight, simple and fast constructed, and relatively low cost; They can use insulation or sandwich panel if there is a need for thermal insulation.

If the warehouse needs thermal insulation, then thermal insulation wool must be laid on the walls and roof. We can provide glass wool or rock wool.

Ventilation

Standard roof-mounted ventilators are typically adequate for regular warehouses that don’t use high-powered heating equipment or produce unusual odors or dust. However, warehouses with unique ventilation needs may require the installation of hostile pressure fans on both the roof and walls to ensure proper air circulation within the facility.

Environmental conditions:

What is the local weather condition? Whether Is there a strong wind and snow in winter?

We will calculate the wind load and snow load of the building to ensure the safety of the building, so please provide the local wind speed (m/s) or the metric area, km/h. If there is snow in winter and we are calculating for a complete design, please tell us how much snow there is on average in your area and if any larger events, such as ice storms or heavy rainstorms, have occurred recently.

Doors and windows:

Do you need doors and windows for the warehouse?

We can provide aluminum windows.

We provided the door according to the request, rolling door, sliding door, and man door.

Parameters of single-story warehouse building:

Length: depends on your requirements.

Column spacing: generally 6m. According to your requirements, it can also be 7.5 meters, 9 meters, or 12 meters.

Span: generally 9-36 meters. We can design it as a single-span, double-span, or multiple spans.

Height: 4.5-9 meters (no overhead crane installed in the warehouse)

When installing one or more overhead cranes in your facility, you should specify the lifting capacity and height of the crane to determine the height of the warehouse building.

The attention to the design:

Focus on the load-bearing design

A steel structure warehouse design requires careful consideration of multiple design aspects. Factors such as weight capacity, pressure resistance, material strength, tensile strength, and load transfer must be considered. The thickness of the steel must also be determined to ensure the structure is strong and functional. A comprehensive process must ensure all these questions are answered and that the warehouse is built to the highest standards.

The design of the steel structure warehouse has been carefully considered to minimize the potential for damage. Additionally, this construction method facilitates regular maintenance and increases the structure’s longevity.

Pay attention to lighting design.

Lighting is an essential factor that can have a direct impact on the atmosphere of a warehouse. To save energy, properly designing the lighting system in the steel structure warehouse is essential. This can be done by placing lighting panels at specific locations on the metal roof, installing lighting glass, and using natural light as much as possible while ensuring waterproofing to maximize the service life. Doing so will result in an optimal lighting effect.

What are the differences between a metal warehouse and a traditional concrete warehouse?

Warehouses are essential for storing goods and commodities and have been traditionally constructed with concrete structures. However, in recent years, the demand for warehouse construction has shifted, leading to the rise of steel structure warehouse buildings. This new model allows entrepreneurs to meet the needs of the market better.

- The construction of the steel structure warehouse is rapid, and the emergency advantages are apparent, which can meet the sudden storage needs of the enterprise.

- The steel structure warehouse is dry construction, which has outstanding environmental protection advantages. It can reduce the impact of project construction on the environment and nearby residents, which is better than the wet construction of reinforced concrete buildings.

- Steel structure warehouses can save construction and workers’ costs compared with traditional concrete warehouses. Building a steel structure warehouse is 20% to 30% lower than a typical warehouse construction cost and more secure and stable.

- The steel structure is light in weight, and the building materials used in the walls and roof are much lighter than those in brick-concrete walls and terracotta roofs, which can effectively reduce the overall weight of the steel structure warehouse without compromising its structural stability. At the same time, it can also reduce the transportation cost of components formed by off-site migration.

The advantages of a Prefab Steel structure warehouse:

1. The design considerations for a prefab steel structure warehouse

1. Structural integrity: The structure must be designed to withstand the loads imposed by the environment, such as wind, snow, and seismic activity.

2. Ease of assembly: The structure must be designed to be easily assembled and disassembled.

3. Cost: The structure’s cost must be considered when designing the warehouse.

4. Durability: The structure must be durable and withstand the elements.

5. Fire safety: The structure must be designed to meet fire safety regulations.

6. Energy efficiency: The structure must be designed to be energy efficient.

7. Accessibility: The structure must be designed to be accessible for people and equipment.

2. Cost-effectiveness

The cost of a prefab steel structure warehouse building will depend on several factors, including the size of the warehouse, the type of steel used, the design’s complexity, and the warehouse’s location. Generally, prefab steel warehouses are more cost-effective than traditional warehouses due to their quick and easy assembly, as well as their durability and low maintenance costs.

Faster design and construction process.

If your warehouse plan is submitted to a steel structure manufacturer company, the building will be pre-designed and manufactured by experts. It makes the entire process from start to finish more economical, resulting in ready-made steel construction components shipped directly to the worksite.

It has reduced labor costs.

Since the warehouse is mostly prefabricated, construction time can reduce by as much as 30% to 50% or more based on the experience level of the construction personnel. Time is money, so the faster you build, the less you spend on labor.

Reduce maintenance costs

Due to the low maintenance cost of the steel structure, the building owner saves on general maintenance, repair, and replacement during the entire life of the building.

3. Endurance

Steel buildings are renowned for their stability, strength, and durability, making them the perfect choice for areas prone to extreme weather conditions, such as high-wind areas and seismic zones. Steel structures resist common threats to wood, such as decay, mildew, pests, and fire. Additionally, steel structures are designed to be more resilient to wind, snow, and seismic activity, making them ideal for disaster evacuation centers and other places where large gatherings may be necessary for an emergency. Steel-framed gymnasiums, schools, and other municipal buildings are often chosen for their ability to withstand typhoons and other natural disasters.

4. Clearspan

The steel structure is economical for large warehouses, manufacturing, and distribution operations. Steel buildings offer the industry’s most expansive architectural clear spans, allowing for more usable space. This means fewer structural obstructions, and installing large-scale industrial machinery, vehicles, and personnel within the building is accessible. The structure also ensures the safe movement of personnel and equipment.

5. Environmental friendly

Eco-friendliness is not just a trend. Data shows that building owners and customers who buy products and services increasingly demand green buildings. The steel structure is a sustainable building product because it uses recycled materials in the production stage and is 100% recyclable at the end of its service life.