Steel structure splicing includes splicing in the workshop and on-site. The splicing methods include welding and bolting. We should implement…

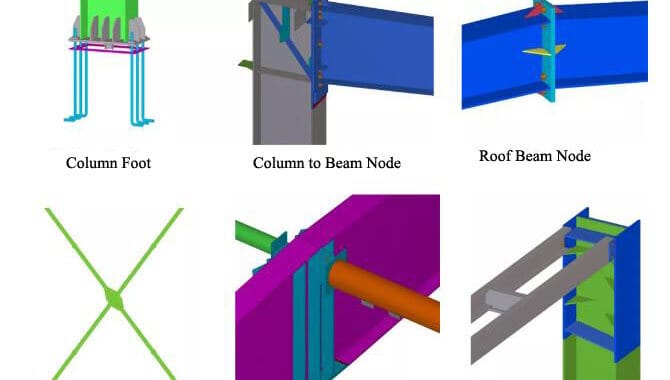

As the light steel roof structure on the concrete column, which has certain advantages in terms of anti-corrosion, and fire prevention compared with buildings using all steel structures, it has been used more and more in China in the past ten years. However, it is still that there is no technical standard for the design and construction of such building structures. The roof is the light steel structure, and the lower part of the roof is the reinforced concrete frame structure. The two structures have different adaptability to expansion and contraction caused by temperature changes. How to correctly set expansion joints has become a difficult point in the design of such buildings. The article will discuss the setting method of expansion joints of this type of structure, which combined with the practical experience.

Basic requirements for expansion joint setting of Steel roof on concrete column

If the building is too long, due to thermal expansion and contraction, it will cause excessive temperature stress in the structure, causing excessive cracks or damage to the building. It is necessary to set a gap in the structure to divide the building into several parts. It can ensure the free expansion and contraction of the building in the horizontal direction. This joint is the temperature expansion joint. For different structural systems, the distance between expansion joints is different. China’s current code has stipulated. “Concrete Structure Design Code” GB50010 specifies that the maximum spacing of expansion joints in reinforced concrete frame structures is 55m. Refer to “Technical Regulations for Steel Structures of Light-weight Portal Rigid Frames”) CECS l02, the maximum distance between light steel roof along the longitudinal expansion joints of the building is 300m. The light steel roof on the concrete column includes a mixed portal rigid frame, which composed of the concrete column and the steel beam. Generally, the cast-in-situ reinforced concrete frame structure is usually along the longitudinal direction. Light steel roof formed from purlins, tie bars, bracing systems, and light roof panels. The distance between the longitudinal expansion joints of such structures should meet the different requirements of cast-in-situ reinforced concrete frame structures and steel roofs.

The width of the expansion joint should meet the requirements of the maximum possible expansion and contraction of the structure and is generally 20 to 30 mm. The width of the expansion joint in the earthquake zone should still meet the minimum width requirement of the seismic joint.

Discussion on the setting method of longitudinal expansion joints of Steel roof on concrete column :

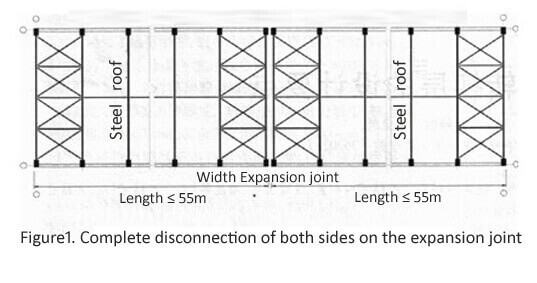

Method One for setting longitudinal expansion joints: A standard way for setting the light steel roofs on concrete columns is to set double columns at a distance of not more than 55m, and the two sides of the expansion joints wholly broken. The precise distance between the two parties is not less than the minimum width of the expansion joint. The light steel roof is disconnected at the same time and meets the minimum width of the expansion joint, as shown on Figure1

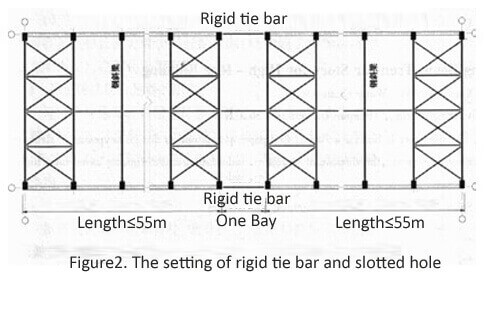

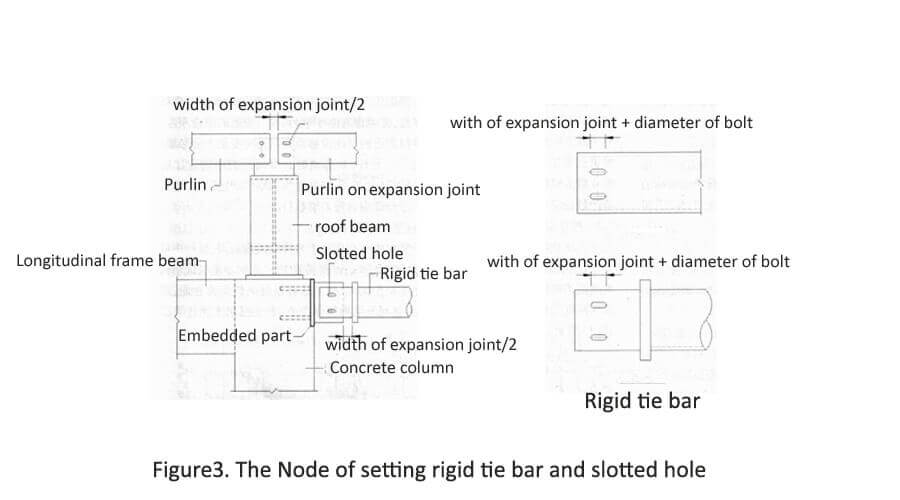

Method Two for setting longitudinal expansion joints: Divided into two or more sections with a length of no more than 55m along the longitudinal direction. An open space between two adjacent segments uses steel pipe, H-shaped steel, double-angle steel, and other rigid tie rods. It hinges connected to the two ends of the column, which the bracing use slotted holes, and corresponding ends of the roof purlins should also use slotted holes, as shown in Figure 2, Figure 3 Show.

The purpose of setting the slotted holes is to release the expansion and contraction along the longitudinal direction when the temperature changes. The total length of the slotted holes should not be less than the width of the expansion joint + the diameter of the connecting bolt. It should have enough clearance between the rigid tie bar and the embedded part at the top of the column, and between the purlin at the expansion joint and the adjacent common purlin to meet the deformation requirements. The size of the gap should not be less than half of the width of the expansion joint.

Each of these two approaches has advantages and disadvantages:

The problem of the complete disconnection of the double-sided structure of the expansion joint is that two columns must set at the expansion joint; two steel roof beams must place at the expansion joint of the steel roof.

The problem of setting rigid tie rods and slotted holes is that: The structural should allow expansion and contraction deformation on the roof sheet. It should enable expansion and contraction deformation of the wall panel at the expansion joint. If the wall panel uses metal cladding, which both ends of wall girts should set slotted holes, and the corrugated metal wall sheets shall construct to allow for expansion and contraction deformation. If masonry retaining walls used, which should guarantee its independent stability, the structure is complicated.

Discussion on the value of longitudinal expansion joint width in the seismic area.

The light steel roof structure on the concrete column in the earthquake zone has the following characteristics:

l) The roof is light in weight, the earthquake action is small. The longitudinal structure deformation caused by the seismic force is low;

2) The span of the longitudinal frame is large, and the rigidity is substantial, which further reduces the seismic effect. Longitudinal structural deformation;

3) If an embedded masonry retaining wall used to provide greater rigidity to minimize distortion,

4) In low-intensity areas (such as six degrees), structural deformation caused by seismic forces is smaller.

Conclusion

1) The longitudinal expansion joints of the single-story building structure of the light steel roof on the concrete column can break entirely at both sides of the expansion joint, and the rigid joints and elongated holes can provide at the expansion joints. The method of completely disconnecting the expansion joint on both sides is relatively simple in construction. The use of a rigid tie bar and the slotted hole is economically advantageous because it is not necessary to provide double columns at the expansion joint and two roof steel beams at the expansion joint. 2) The width of the longitudinal expansion joint of the steel roof on the concrete column in a non-seismic zone is generally 20-30mm, and the width of the longitudinal expansion joint of a single-story house structure with a light steel roof on a concrete column in the earthquake zone can be 50 —70mm. When the number of longitudinal spans is large, and the seismic fortification intensity is low, it recommended that the width of the expansion joint comprehensively determine concerning the calculation result of rare earthquake deformation.