In the construction of modern storage facilities, steel structure warehouses have become one of the mainstream building forms due to…

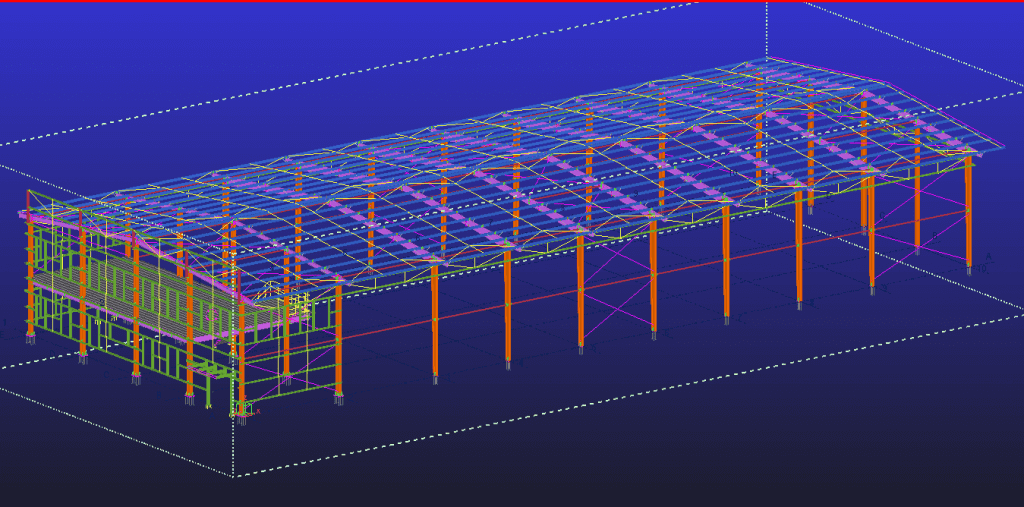

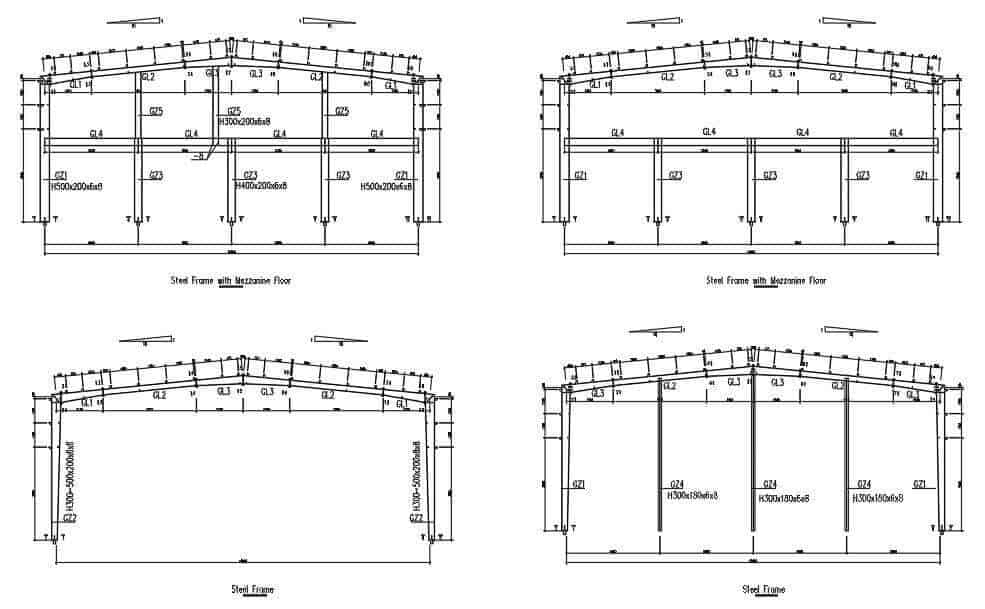

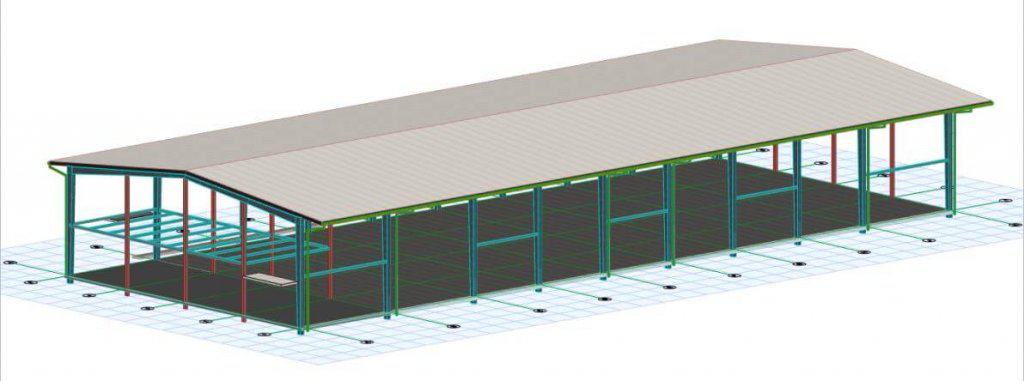

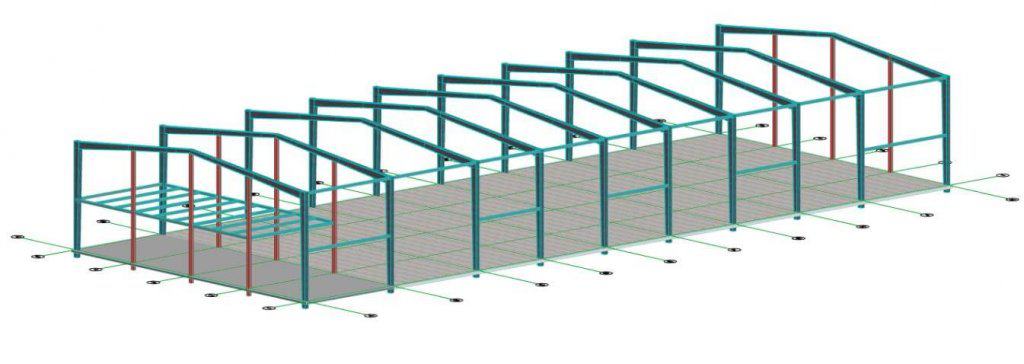

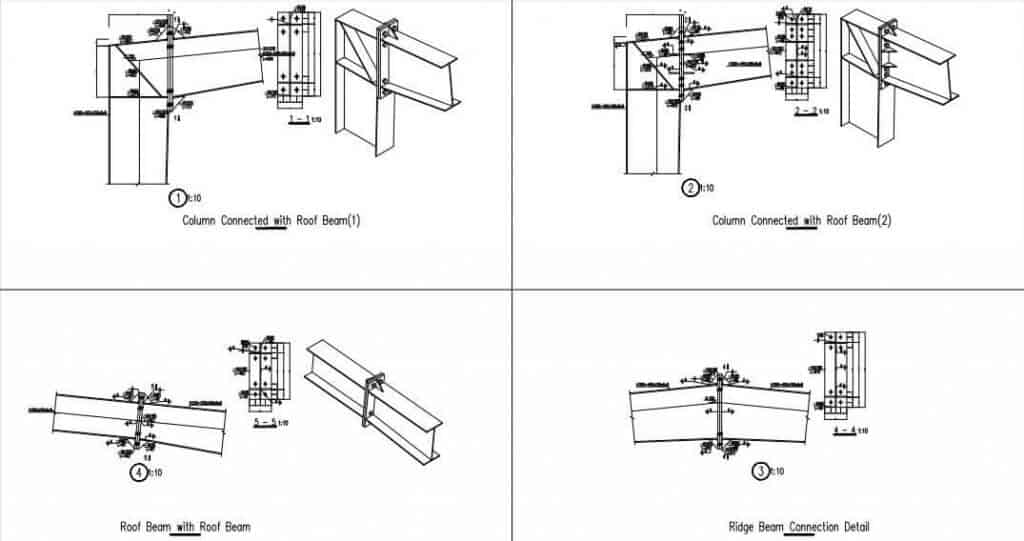

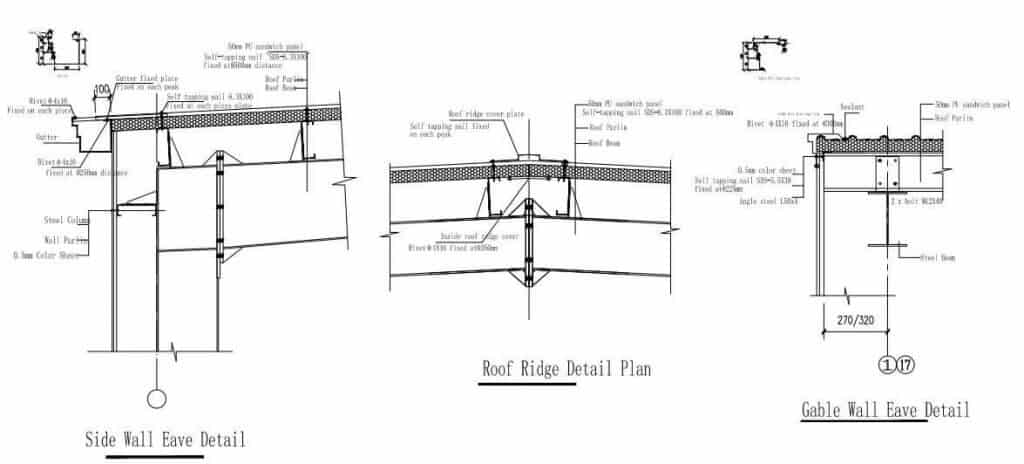

Steel Warehouse Building Design is crucial in the whole project. In this process, design drawings play an essential role. Design drawings include two categories: structural drawings and construction drawings. The structural drawings mainly show the overall framework of the steel warehouse building, detail the size, material, and connection details of each structure part, the layout plan of each component, and other detailed information about the structures.

The construction drawing is a guiding blueprint for the specific implementation stage, which describes in detail how to assemble and connect these steel structure components, covering every detail from foundation to roof installation. The accuracy of the construction drawing directly affects the construction progress and quality of the project, ensuring the smooth progress of each stage. Therefore, the design drawings of the steel structure warehouse are not only theoretical planning, but also the key basis for the successful implementation of the project.

The loading-bearing member of a warehouse building mainly includes components such as columns, beams, and connection plates, which together constitute a solid steel frame. The steel frame plays an essential role in the overall stability and safety of the building.

If the cross-sectional size of the steel frame is too small to bear the load required by the warehouse, especially in strong winds or rain and snow weather conditions, it will cause structural instability or even collapse. On the contrary, if the cross-sectional size of the steel frame is too large, it will waste steel and increase the construction cost. Therefore, at the primary stage of steel warehouse building design, structure engineers will analyze and calculate according to the local construction to determine the reasonable component size, which can not only ensure strength but also save materials and improve economic benefits.

Steel Warehouse Building Design in Tanzania

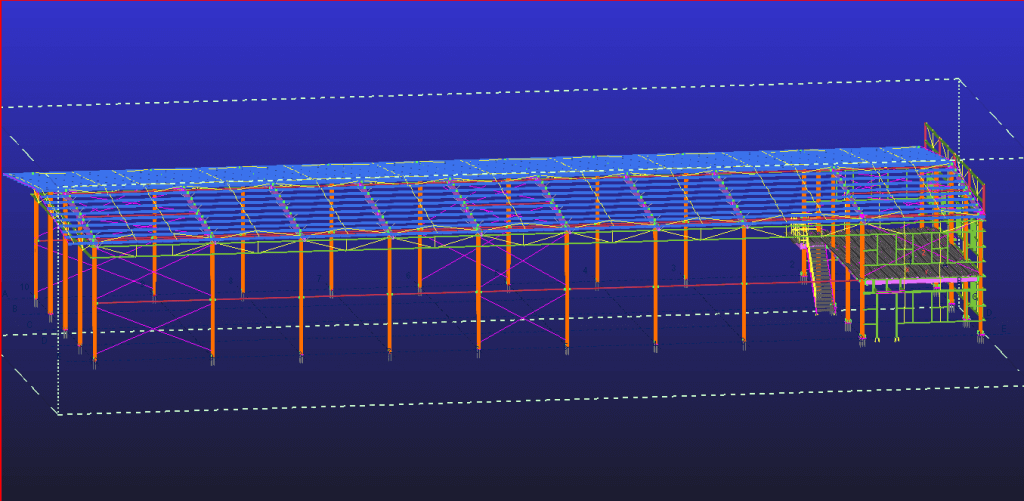

Steel warehouse building design and manufacture for Tanzanian customers is 2,000 square meters.

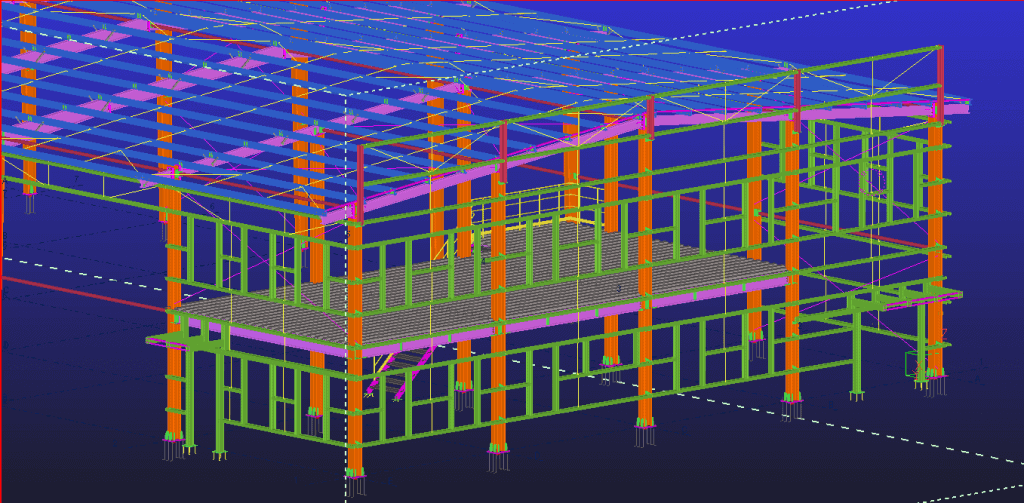

The warehouse is 100 meters long, 20 meters wide, and 7.7 meters high. Its stable structure is adapted to local climatic conditions. In the front of the warehouse, there is a 4.5-meter-high mezzanine, which is used exclusively for office work and makes full use of the vertical space.

Parameters of the Tanzania metal structure warehouse building:

Dead load: 0.3kn / m2

Live load: 0.5kn / m2

Wind load: 0.6kn / m2

No snow

Earthquake: 7 degrees, 0.1g

Brick wall height: 5 meters

Design Software: PKPM

The Calculation of Prefab Steel structure Warehouse Building

The calculation of the single steel frame, width: 20 meters, height 7.7 meters, column spacing 6.25 meters, slope: 1:10. Steel: Q345B

Connection method of steel beam and steel column: bolt connection

Steel columns are connected to the foundation through the embedded anchor bolts.

Anchor bolt: M20x900, four anchor bolts per column

The components of Steel structure warehouse building

Steel columns and beams: welded H-beams

Roof horizontal bracing, wall bracing: round steel

Tie rod: welded pipe

Roof purlins, wall girt: galvanized C-type purlins, purlin spacing: 1.5 meters.

Sag rod: round steel

Roof panel: 50mm polyurethane composite board

Wall panel: 0.5mm color metal cladding

Advantages of prefabricated steel structure buildings

- Wide range of uses:

This is an easy-to-use, durable and well-designed solution for construction applications. This can be used as factories, warehouses, office buildings, stadiums, aircraft hangars, etc. It is suitable for single-story large-span buildings and applies to building multi-story or high-rise buildings. - Short construction time

All components are prefabricated in the factory, and only simple assembly is required on-site. The result? Less construction time and saving of resources, including energy, materials, and manpower. - Easy to maintain

The calculated steel structure building is resistant to severe weather and simple maintenance. - Reasonable cost:

Steel structure building is light, low cost, and easy to build. It can complete and put into production as soon as possible. Compared to concrete structure buildings, it has many advantages such as durability, beautiful appearance, and good expansibility, which are suitable for use on all kinds of occasions.