The service life of steel structure buildings is more than 50 years. The roof and wall panels of prefabricated steel…

Havit Steel Structure designed a steel structure warehouse in Benin, which use as logistics warehouses. Benin is located in south-central West Africa, with a population of approximately 11.2 million, a land area of 112,600 square kilometers, and its official language is French.

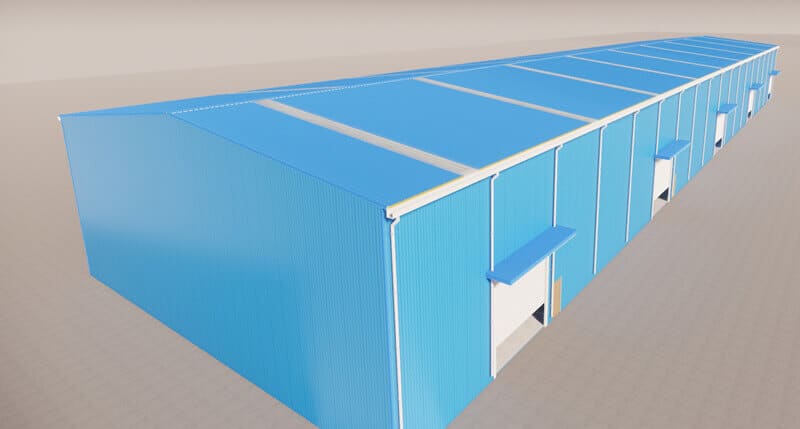

Design of Steel Structure Warehouse in Benin

The building area of the warehouse is 2500 square meters, with a length of 100 meters, a width of 25 meters, and a height of 10 meters single floor warehouse building. The size of the rolling shutter door is 5mx5m. The roof and wall panels use the glass wool sandwich panel, and the thickness is 50mm.

Features of glass wool sandwich panel:

- Glass wool sandwich panel has a high closed cell rate and excellent energy-saving effect;

- Green and environmental protection, no formaldehyde;

- Unique plug-in interface design, stronger resistance to negative wind pressure;

- Diverse shapes, beautiful and elegant advantages: no cold bridge, high rigidity, good flatness, glass wool A-level non-combustible;

- Tight plug interface, no heat conduction of steel plate

- Unique connection design, stronger resistance to negative wind pressure;

- Good fire performance: suitable for walls and roofs of large public buildings, industrial plants, and other buildings that require fire protection.

Steel Structure Warehouse in Benin

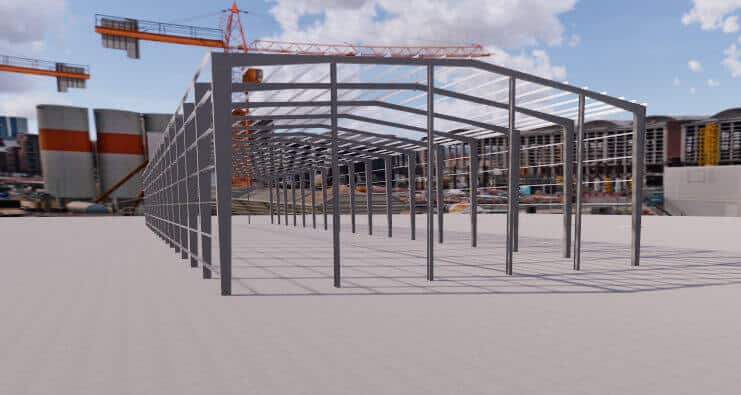

The steel structure warehouse in Benin design as portal rigid steel frame, the steel column and roof beam use H-shaped steel, the primary structure are designed according to Q345B steel, and the secondary system uses Q235B steel. The roof purlins are Z-shaped steel, and the wall girts are C-shaped steel.

We design as the 25-meter clear span, without pillars in the middle. Large internal use space increases the use area of the warehouse.

The difference between steel structure warehouse and concrete warehouse:

Duration:

In terms of the construction cycle, the steel structure has obvious advantages. The construction of the steel structure warehouse is very fast because it is built in the factory and produced on the construction site. Only hoisting and splicing can satisfy the needs of some manufacturers for an emergency warehouse building.

Environmental Friendly:

The operation of the steel structure warehouse is as mentioned above. After it is transported to the construction site, the components only need to be hoisted and spliced. The whole process can be operated without water. There is no flying sand and a large amount of dust, which can reduce environmental pollution and impact on nearby residents. It is not possible with concrete buildings.

Cost:

Steel structure saves construction and labor costs more than concrete. The price of building a steel structure warehouse is 20 to 30% lower than that of traditional concrete buildings, and steel structure is more robust and more durable than concrete.

Structure Weight:

The steel structure itself has the characteristics of lightweight. The walls and roofs of the steel structure are made of light metal building materials, which are much lighter than the brick-concrete wall terracotta roof, which can reduce the overall weight of the warehouse. Will damage the stability of the structure.