The service life of steel structure buildings is more than 50 years. The roof and wall panels of prefabricated steel…

Steel residential building kits refer to the house buildings that use steel structure as the load-bearing members. Steel structure houses divided into light steel structures and heavy steel structures. Light steel structures generally use as low-rise residential buildings, and high-rise residences use the heavy steel structures.

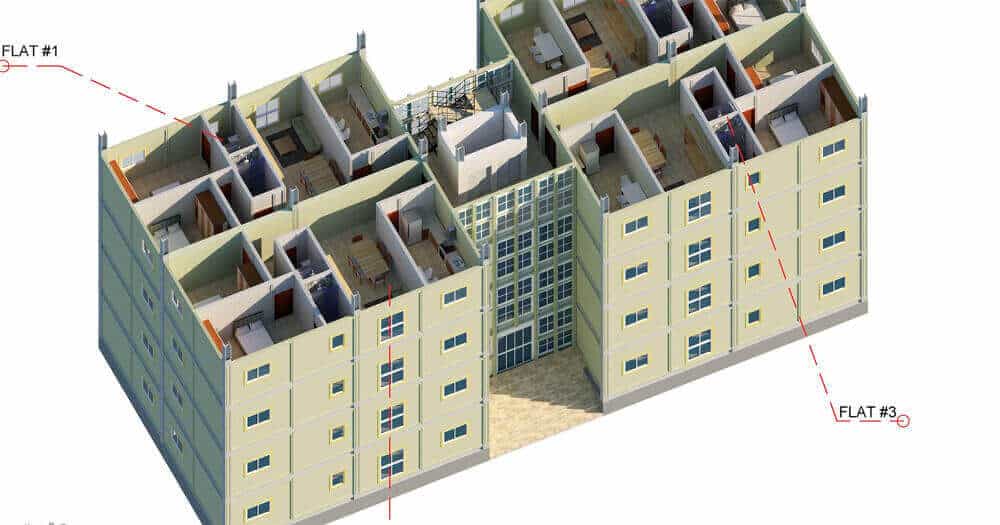

High-rise Steel residential building kits

The high-rise steel structure residential system is different from the traditional brick-concrete structure system and concrete structural system. It is mainly composed of a load-bearing steel structure system, floor structure system, and enclosure structure system.

The high-rise steel structure residential system uses the frame structure composed of H-shaped steel beams and columns. The cross-sectional shape of the H-shaped steel is in line with the laws of mechanics, the internal density is even, and the force is balanced. Its self-weight is lighter, and the H-shaped steel structure is much lighter than the concrete structure, which can reduce the requirements for the foundation treatment of the building structure, simplify the construction and reduce the cost.

The wall of high-rise steel residential building kits use hollow bricks or aerated concrete panel. It can also adopt a light steel framework with cast mesh and cast-in-place lightweight concrete as the wall structure. The building structure can also use as office buildings, hotels, etc.

Floor structure system

The floor structure is composed of steel floor beams and floor panels. In addition to the direct distribution of vertical loads to the walls and columns, the main function of the floor is to participate in and ensure spatial synergy with the lateral structure. Therefore, it is necessary to ensure that the floor has sufficient strength, rigidity, and overall stability. At the same time, technical and structural measures should be adopted to reduce the self-weight of the floor and increase the construction speed. As the floor structure of civil residences, floor slabs should also have good heat insulation, sound insulation, heat preservation, waterproof and fireproof performance. To ensure the overall stability of the steel beams, compact construction measures should be adopted for the primary and secondary beams on the floor.

The main types of floor slabs currently used are as follows:

Profiled steel plate: the cast-in-place concrete composite floor.

In the overall analysis, the designer should consider the influence of the anisotropy of the composite floor slab on the frame beam.

(1) Determine whether it is a continuous slab or a supported slab and whether the force transmission path is one-way or two-way according to the floor setting;

(2)Whether the composite steel beam is strong or weak in stiffness caused by edge combination.

Precast concrete laminated floor: The steel beam is connected with the prefabricated prestressed concrete sheet, and the concrete sheet is poured on to form a laminated floor. Because this kind of floor slab not only has the integrality of the cast-in-place composite floor, it can also omit profiled steel plates and does not require formwork, which is convenient for construction and can reduce the cost of floor slabs, so it should be the first choice.

Advantage:

- The structure is lightweight, high-strength, earthquake resistance is good, and the project cost is low.

- The external appearance is beautiful, the space layout is flexible, and the building function is enhanced.

- It is easy to transform, and the pipeline layout is convenient.

- Meet the requirements of energy-saving and environmental protection.

Disadvantages:

1. The fire resistance of steel structures is weak, and the steel structure needs to coat with fire-resistant coatings.

2.Poor corrosion resistance. Steel components rusted when exposed to a humid environment. The surface of the steel components needs to shot blast, painted, or galvanized.

Light Steel residential building kits

Another type of Light Steel residential building kits called a modular building. The structure uses the H-shaped steel and tube to form floor beams. The wall keels use square pipes to support the load. The wall materials mainly include insulation cotton, plywood, gypsum board, cement fiberboard, exterior wall decorative board. The structure divides the entire building into several modules. The pipelines, waterways, and internal decoration in the module are prefabricated in the factory, and then each module is assembled on-site to form a whole house.

Advantages :

1. Fast construction, which can shorten the construction period by 50 ~ 70% compared with traditional concrete buildings.

2. The degree of assembly is high, which can reach more than 85%. Most of the construction work, including installation of water, heating, electricity, sanitation, and other facilities, and house decoration, is moved to the factory to complete.

3. environmental friendly.

4. Convenient for later expansion.

Disadvantages :

1. The transportation cost is high. The size of each module is ultra-wide, and the width is about 3.5 meters. It needs to transport through the ultra-wide trailer. The shipment needs to be carried by a bulk vessel or a particular frame box.

2. The installation process requires the use of large equipment.

3. The area of a single module is limited, and the field of each module cannot exceed 50 square meters.

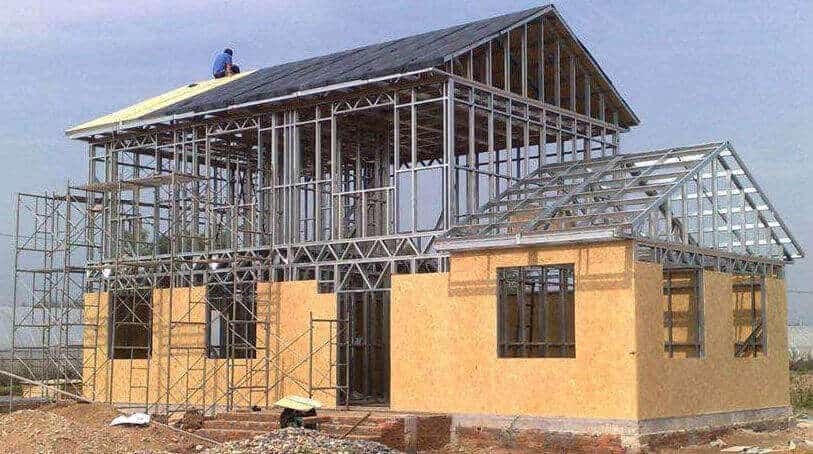

Light Steel Structure house

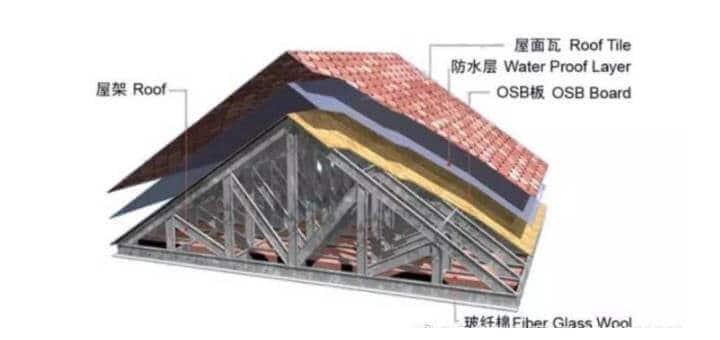

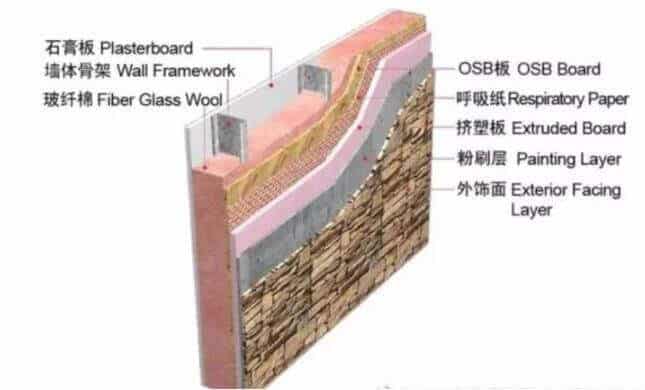

There are also light-steel residential building kits, usually called a light-steel villa or light-steel house. The support structure is a light-steel keel, which synthesized from hot-dip galvanized aluminum steel strip through cold rolling.

Common materials and thicknesses of light steel structure houses :

1.Light steel keel: 75mm, 90mm

2.OSB board: 9mm, 12mm, 15mm

3.Glass wool: 50mm, 75mm, 100mm

4.Calcium silicate board: 6mm, 8mm, 10mm, 12mm

5.Paper surface gypsum board: 9.5mm, 12mm

6.XPS insulation board: 20mm, 40mm, 50mm

7.SBS waterproof membrane: 3mm, 4mm

8.External wall hanging boards: 7.5mm, 15mm, 18mm

Advantages:

1. The site construction speed is fast and will not affect the nearby residents in favor of civilized construction.

2. The light steel villa has the lightweight and excellent seismic performance.

3. light steel villas because the light steel structure of the wall thickness is small then the brick-concrete structure can increase the active area.

4. The construction of light steel villas adopts a dry construction method, which will not cause waste of water data. And save money.

Disadvantages

1. To build a light steel house, you need to find an engineering team specializing in bright steel. The construction cost is also slightly more expensive than traditional bricks.

2. The sound insulation effect is much worse than conventional brick-concrete houses. Light steel structure houses have thin walls, and the material itself is not soundproof.

3. The light steel keel is not fire-resistant, blisters, and moisture resistant. Not suitable for construction in the rainy and humid south.

4. Light steel houses have thin walls, and the material itself is not a thermal insulation material, so it cannot adapt to the cold north.