Steel Building Specification

Steel Building Specification provide the basic information about the Prefab Steel Building, which include Warehouse, Workshop, Shed, and Garage Building.

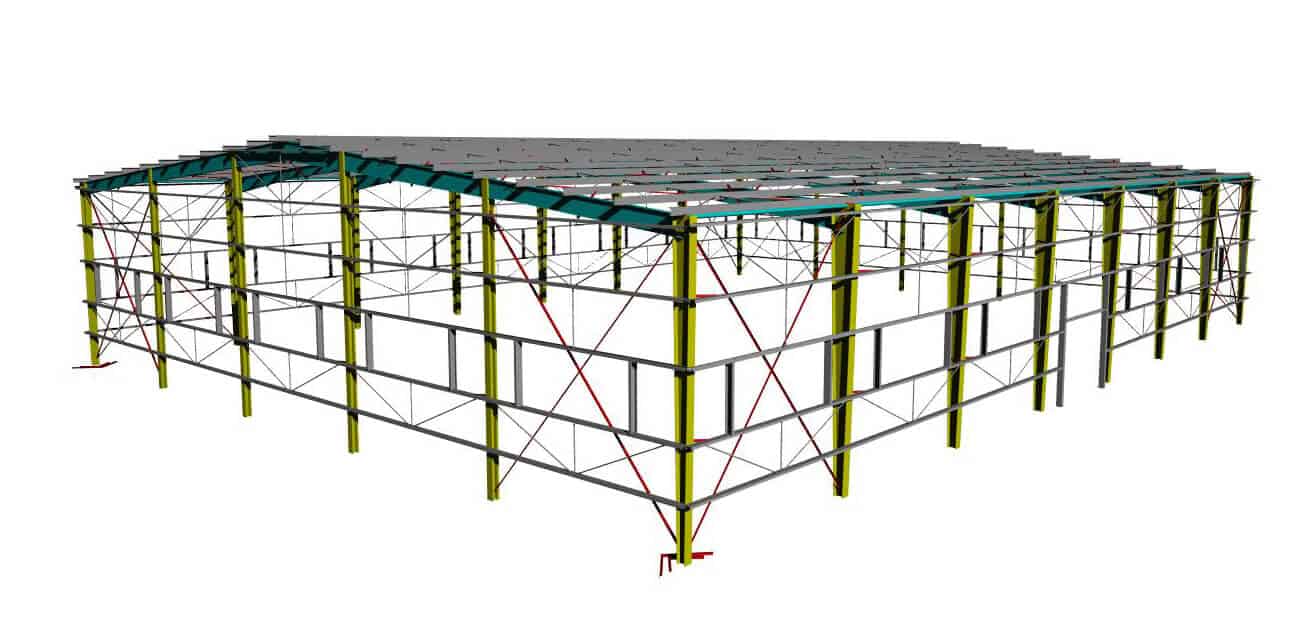

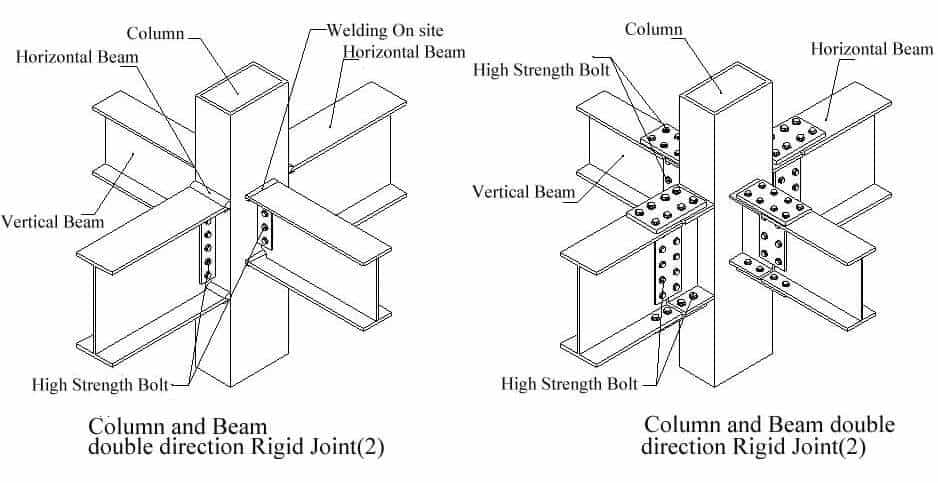

Steel building is a structure composed of steel materials, which comprised of steel columns, steel beams, steel trusses, and other components. The parts usually connected by welding or bolts. Because of its lightweight and comfortable construction, it widely used in Workshop, Warehouse, Stadiums, and High-rise buildings.

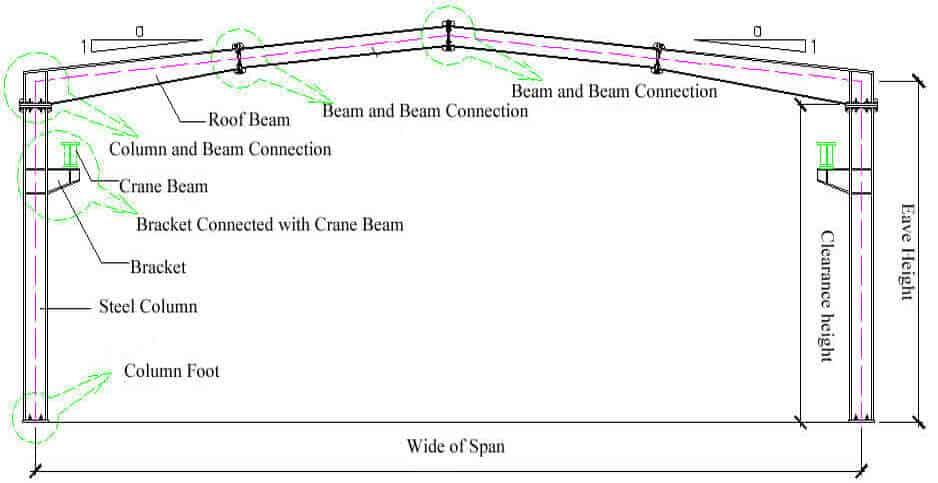

Steel Building Specification- Portal Frame

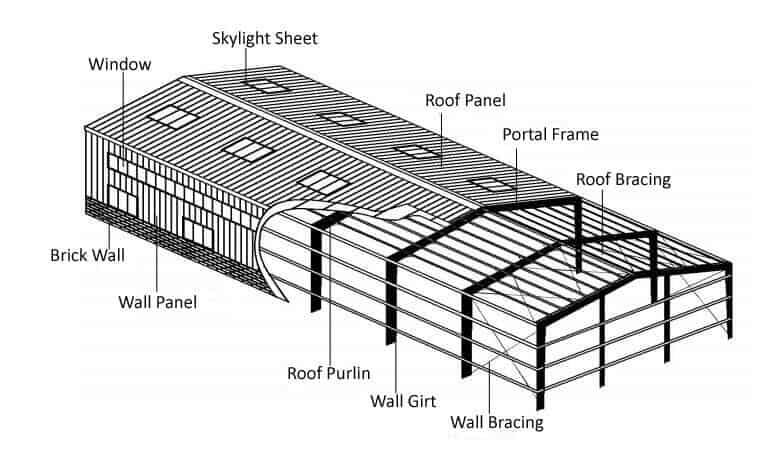

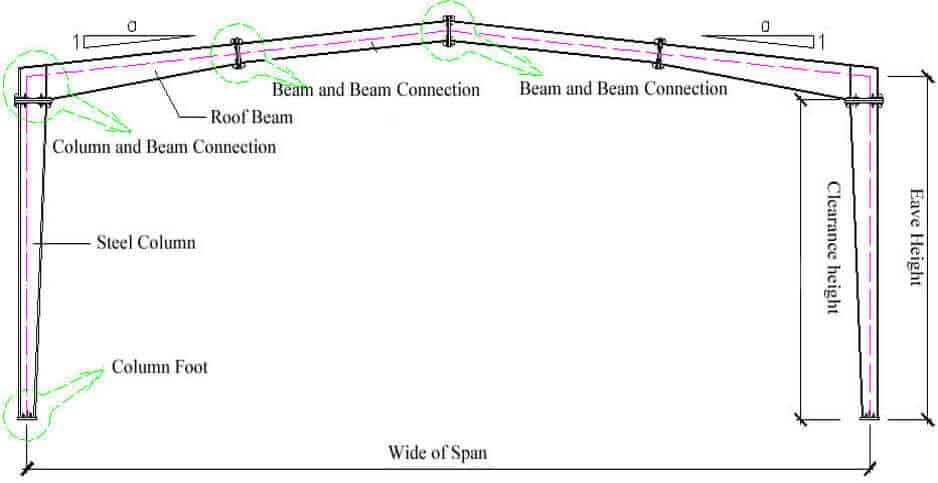

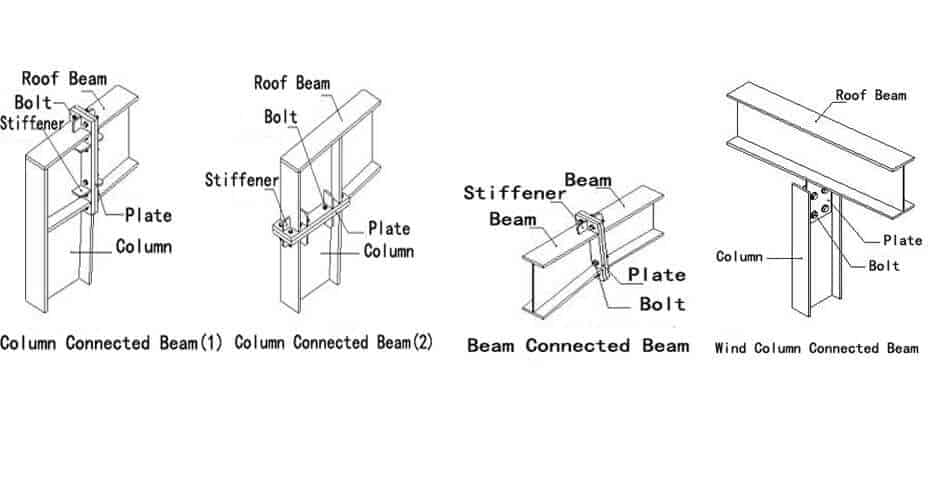

The portal steel frame is a traditional structural system. The mainframe includes Steel Column and Roof Beam, and the secondary structure includes Bracing, Strut, Purlins, and tie rods.

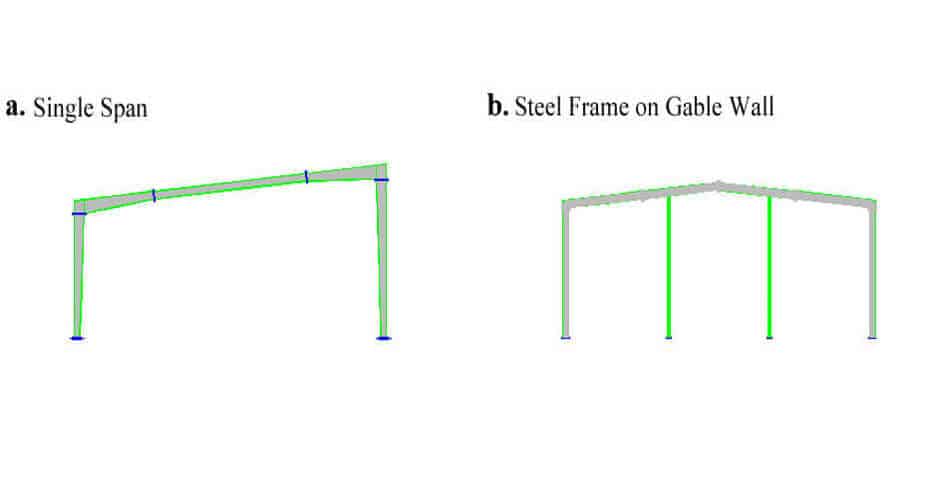

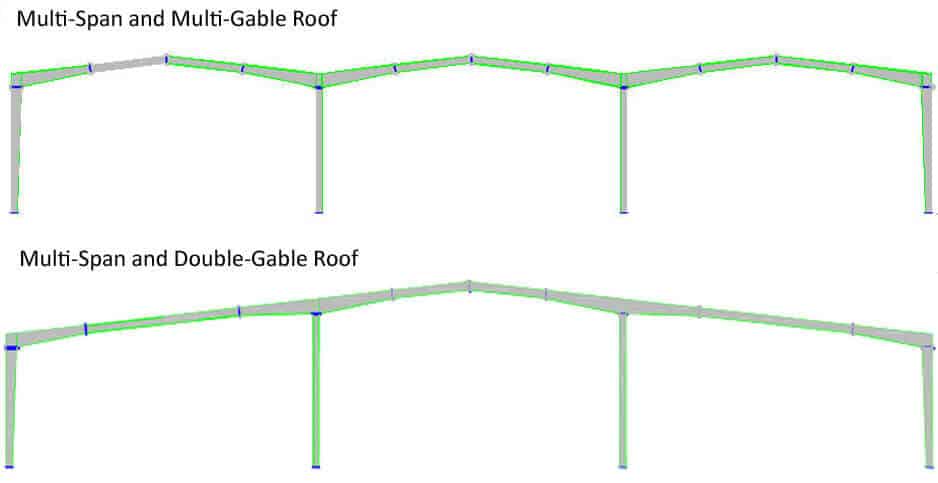

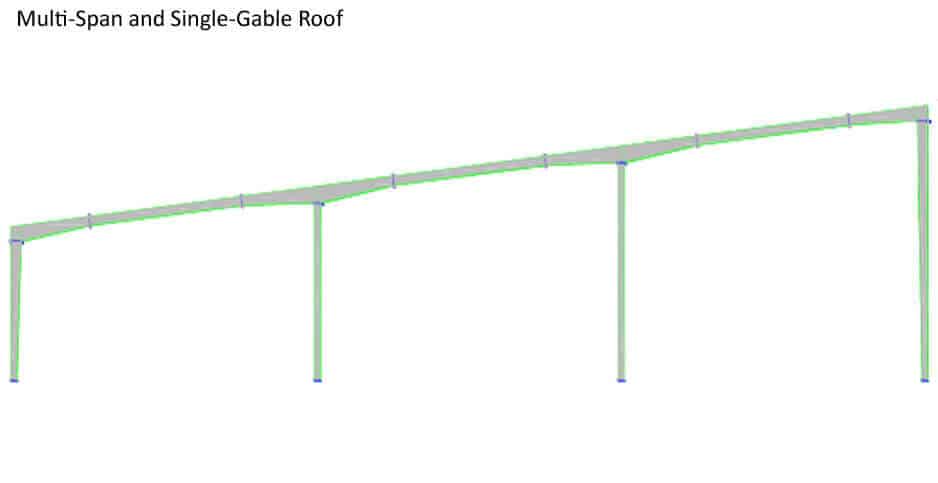

The Structural of Portal frame divided into Single Slopes, Double Slope, Multi-span with multi-gable roof, Multi-span with double-gable roof, and Muli-span with the single slope.

Steel Structure Detail

Steel Structure detail shows the specification of the portal frame structure, which most common use building structure for Warehouse, Workshop, Garage

The Spec of Steel Frame Building

A steel frame building is a load-bearing framework composed of steel columns and steel beams fabricated by section steel or…

The Specification Of Portal Steel Frame Buildings

The portal steel frame buildings are standard steel structure. Its appearance is similar to that of a door frame. It…

The advantages of Steel Buildings

Steel Building Specification - Type of Portal Frame

The portal frame structure is mainly composed of steel columns and roof beams, and the frame is a plane loading system. To ensure longitudinal stability, which column bracing and roof bracing will arrange.

The portal frame divided into several forms, 1. Typical portal steel frame. 2. Steel frame with the crane. 3. Steel frame with mezzanine structure.

Steel Building Specification - Connection Detail

Steel Building Specification - Secondary Structure

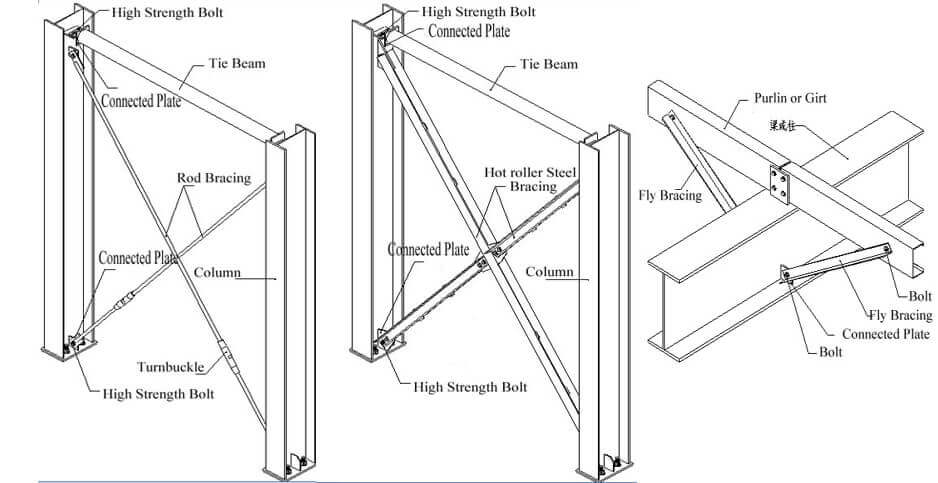

Bracing Structure

The portal frame,purlin,Bracing system and the metal cladding rely on each other through reliable connection and support.

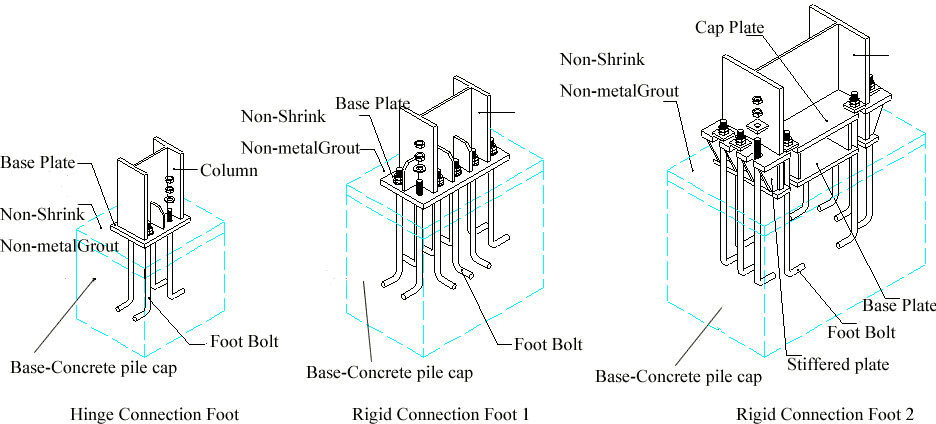

The main structure of the portal frame load-bearing structure divided into two types according to the kind of the rigid frame: the clear span structure without interior columns and the multi-span continuous structure with interior columns.

According to the specific project, it can also be used in single and multiple slopes, as well as in different spans and heights. Most of the foundation types adopt reinforced concrete independent foundations. According to the diverse requirements of the building for lateral displacement and deformation, from the perspective of saving steel, a variable-section beam-column, foundation hinge structure scheme, or an equal-section column variable-section beam, foundation rigid structure scheme can be adopted.

Bracing System

The main functions of the bracing system are:

1) The strut beam transmits the longitudinal horizontal force.

2) The horizontal bracing resists the horizontal force transmitted between the columns and roof beams.

3)Flange Bracing use to keep the stability of the outer plane

4) All bracing systems, together with purlin or wall girt and portal frames, which form a space system, which ensures the overall function of the space of the structure, bear, and transfers horizontal loads, and ensure the stability and convenience during the installation.

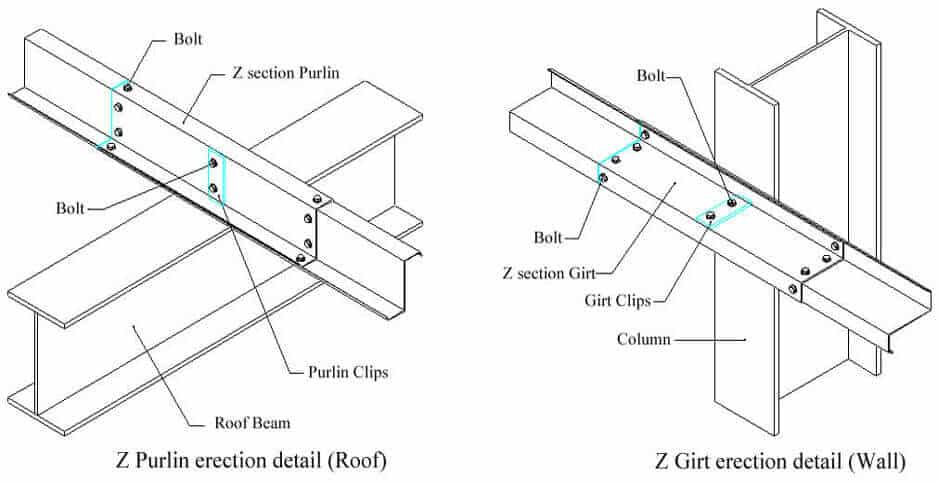

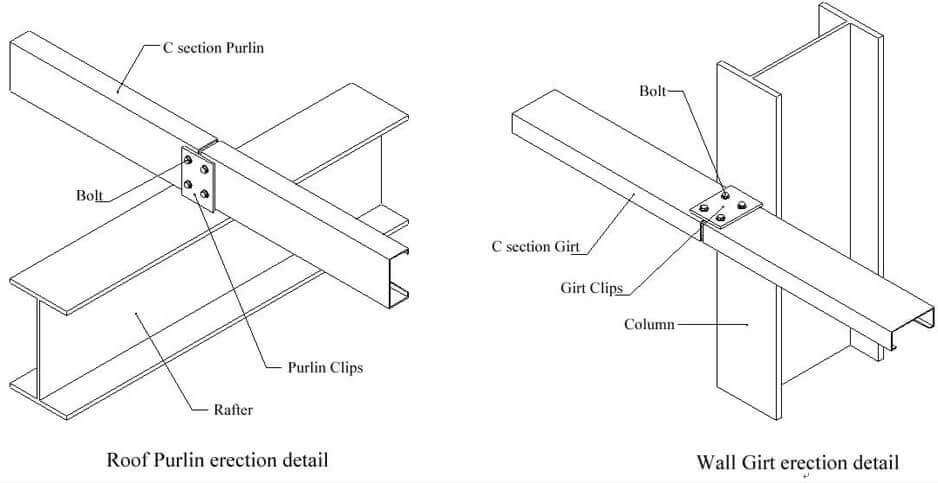

Purlin and Wall Girt

The main component types of purlins and wall girt are C-type or Z-type steel, and the size of the cross-section needs to determine through the load calculation. Compared with the Z-section, the mechanical properties of the C-section are quite different, C section steel connects to the portal frame bolted.

The Z-section can rigidly connect by substantial overlap, which can calculate as a continuous beam.

Therefore, in addition to door and window openings and other specialized areas, Z-sections should be preferred. The distance between the purlin and the wall girt usually not exceed 1.5 meters.

Application Range

The application of the portal frame light steel building, which includes single-story industrial buildings, includes Warehouse, Workshop, and Storage Building, Commercial Building includes Supermarkets and Exhibition halls, and Agricultural Building includes Metal Barn, Poultry, and livestock building.

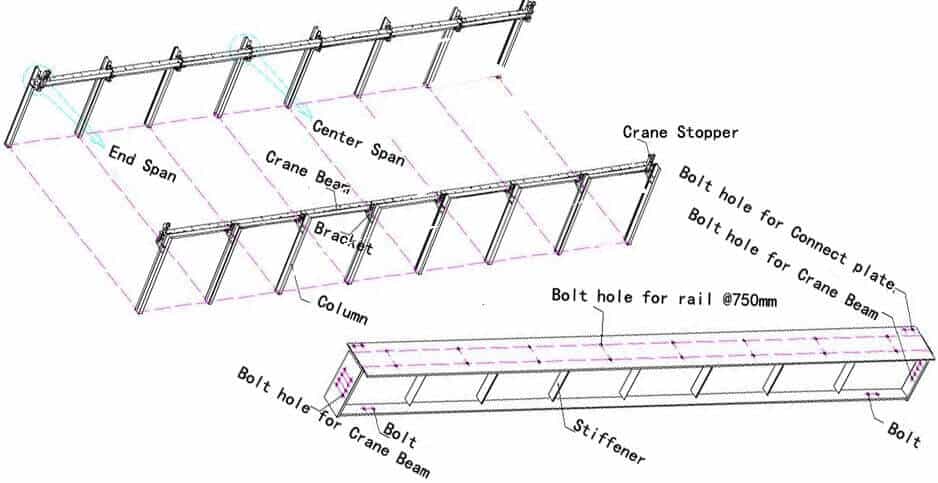

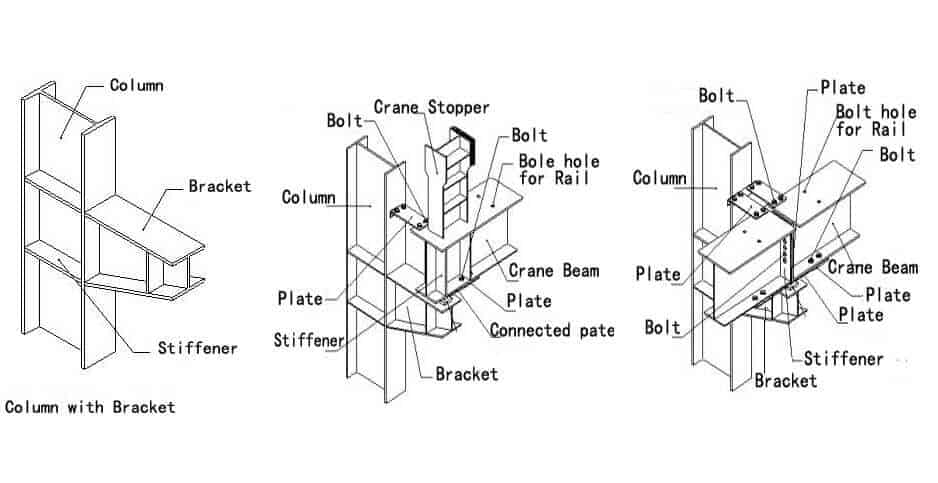

Steel Building Specification - Steel Frame with Crane Beam

Crane beams used to load crane inside the workshop, which installed on the upper part of the frame and works together with the steel structure building.

Features:

-

-

- The crane beam used to support the operation of the Crane, which mostly used in the steel structure factory building.

- There is a crane rail on the crane beam, and the crane travels back and forth on the crane beam through the railing.

- The crane beam is similar to the steel beam, and the difference is that the stiffeners welded on the web, which use to provide support for the lifting of heavy loads

-

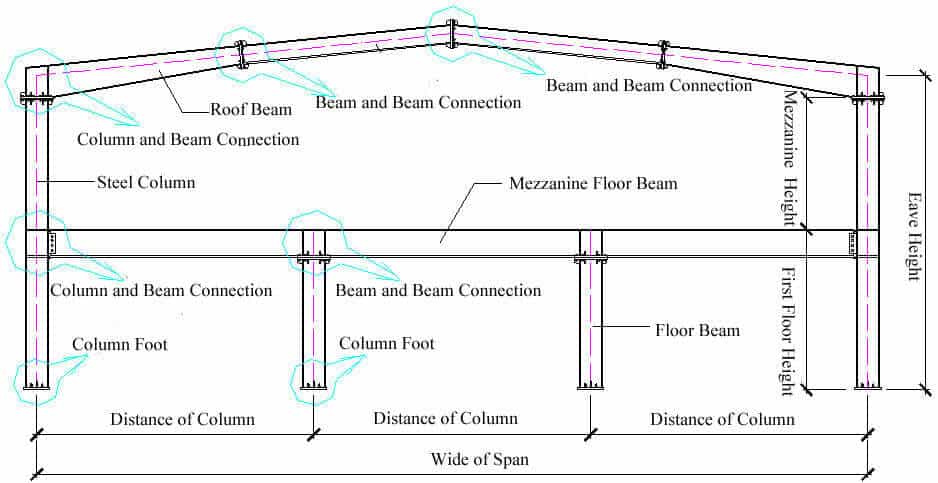

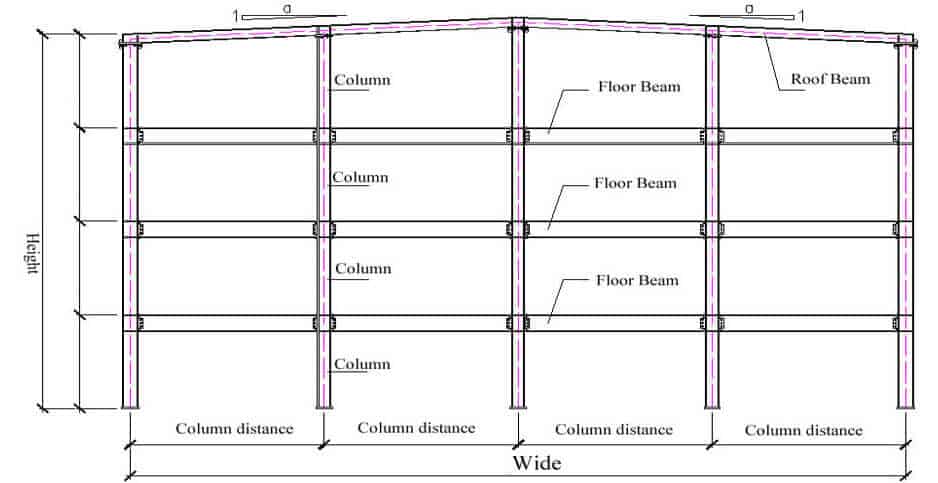

Steel Building Specification: Multi-stories Steel Frame

The multi-stories steel frame is composed of steel beams and columns and can withstand vertical and horizontal loads. The frame structure should meet not only the requirements of strength and stability but also ensure the overall strength of the frame

The steel frame has ample internal space and flexible layout, which can meet the needs of different buildings, and the construction speed is fast. The steel frame structure mainly made of steel, which is one of the main types of building structures.

Multi-stories Steel Frame

The Applications of Steel Buildings

Steel structure buildings are not unfamiliar in our daily lives. In every corner of life, you can find steel structure buildings with a little attention. The application of steel structure buildings has been quite common. Today, let’s sort out where steel structure buildings are mainly used.

The steel buildings we are familiar with

1. Steel structure workshop

Steel structure workshops are generally divided into light steel structure workshops and heavy steel structure workshops.

Regular industrial steel structure workshops are generally light steel structure workshops, such as chemical plants, breweries, door and window factories, glass factories, farms, farms, etc. The light structure of the roof and outer walls of the steel structure factory building usually uses H-shaped steel as the beam and column surface, and the joints are rigid connections. The steel structure factory building comprises beams, steel beams, braces, roof panels, wall panels, etc.

The heavy steel structure workshops are basically equipped with cranes. Steel skeletons are often used in workshops with heavy crane lifting capacity or heavy work. Such as the open hearth, converter workshop, they are mixing furnace workshop, blooming workshop of the metallurgical plant, the steel casting workshop, hydraulic press workshop, and forging workshop of the heavy machinery plant.

2. Steel structure warehouse

The material and structure of steel structure warehouses are similar to those of regular light steel structure workshops. Still, the design of steel structure warehouses is relatively simple. The materials are more practical, the cost is relatively low, the load-bearing capacity is rather large, and the materials can be recycled and used.

Relatively simple steel building:

1. Steel structure foyer

It is an annex hall that expanded on the original building or the factory building. This kind of architectural hall design in advance through a computer, and the construction period is shorter, and the workload is less, so the installation is faster.

2. Steel structure flyover

This kind of flyover would like to say that there are fewer procedures, no need for pouring and maintenance, the construction speed is relatively fast, and the disassembly is very convenient. The recycling value is relatively high. Therefore, it is suitable for quick and civilized construction.

3. Steel structure platform

The steel structure platform is designed according to the actual situation of the building to make full use of the original space, improve the utilization rate of the area, and assist the production work. Therefore, the steel structure platform widely uses in people’s production and life. The more common steel structure platforms mainly use factories, logistics storage warehouses, steel structure stages, cinema platforms, etc.

4. Steel structure canopy

Many building communities and shopping malls use steel structure canopies to decorate their stores, which are beautiful, economical, and applicable and shelter people from wind and rain. The use of steel canopy brings a lot of convenience to people’s lives.

5. Steel structure residence

Steel structure houses and steel structure villas are not very rare buildings anymore. Much rural self-contained housing, factory dormitories, hotels, tourist attractions, etc., are already using steel structure residential houses.

More complex steel buildings

1. Large span structure

Such as aircraft assembly workshops, hangars, conference halls, stadiums, exhibition halls, high-speed railway stations, large shopping malls, etc., all require large-span structures. Its structural system can be net frame, suspension cable, arch frame, and frame, etc. Compared with steel structure workshops and warehouses, the structure and design are more complicated.

2. Tower mast structure

Including tower mast structures, such as TV towers, microwave towers, transmission line towers, drilling towers, environmental atmospheric monitoring towers, radio antenna poles, broadcast transmission masts, etc.

3. Multi-storey, high-rise, and super high-rise buildings

The framework of multi-story and high-rise buildings can adopt steel structures. For multi-story frames in industrial buildings and high-rise or super high-rise buildings such as hotels, restaurants, office buildings, frame structure systems, frame support systems, and frame shear wall systems should be adopted. In recent years, steel structure has been gradually developed in this field.

4. Removable or movable structure

Mobile houses for commerce, tourism, and construction sites are mostly lightweight steel structures connected with bolts or fasteners.

5. Other structures

Such as trestle bridges, pipeline supports, derricks, and offshore oil production platforms.

The application of steel structure building is more extensive; due to its advantages, the proportion of steel structure building will become larger and larger. The national government strongly supports the development of steel structure buildings. It appeals to the people to hide steel, which is also a general trend in the development of the construction industry in the future.

How to improve the efficiency of steel structure buildings?

We all know that steel frame buildings’ rapid development and popularity largely depend on steel structure construction’s high efficiency to build a workshop or warehouse. The owner wants to put it into use as soon as possible to get profits. Steel structure building is the first choice. Because if you choose to use a steel structure, from planning to putting it into use, it can be completed within a few months if the progress is smooth. So in what ways can steel structure building improve efficiency?

1. Design efficiency

The first and most crucial step at the beginning of steel structure building is drawing, planning and design. Nowadays, it takes much less time to design steel structures than in the past. The first is that the designer has rich experience, but the designer uses various accurate computer software to increase the design speed a lot. Designers can use design software to simulate and design a solid structure and use as little steel as possible to make the most reasonable design within the safe range of values so that the price can keep at a low level.

2. Production efficiency of steel components

After the design drawing is confirmed, the factory will fabricate the components according to the drawing. Choosing the proper steel structure factory is very important because selecting the right factory can improve the quality and speed of component fabrication. It’s not that the bigger the factory, the better. If your building is not very large, it may not be wise to find a large-scale steel structure factory. Because when the factory is busy, it is possible to delay your component manufacture time and affect the efficiency of component production. Of course, it is best not to choose a steel structure factory that is too small because a factory that is too small may not strictly follow the fabrication standards of the components to reduce costs. It will not arrange professional quality inspectors to conduct quality supervision.

3. Transportation efficiency

The packaging and transportation of steel components is also an essential part of it. Especially for international projects, inexperienced factories are not familiar with the packaging and transportation of steel components. Improper packaging and transportation may cause damage to the steel components and affect the progress of the entire project.

4. Installation efficiency

The quality of steel structure installation determines the quality of the entire steel structure building. It is best to choose an experienced and professional installation team to ensure installation efficiency. Generally, the installation time of steel structure buildings is one-third less than the construction time of other building systems.

5. Operational efficiency

The maintenance cost of the steel structure building is meager, and the number of repairs required is also small. Equipped with an effective thermal insulation system will also reduce prefab metal buildings’ energy costs.

6. Use efficiency

The steel structure building has a long service life. If the design is reasonable, the component quality is qualified, and the maintenance is timely, the steel structure building can be used for more than 50 years. When the service life of the metal building exceeds its service life, the steel components can be 100% recycled, saving money.