A steel frame is a structure made of steel, usually connected by welding, bolting, or riveting steel beams, columns, bracing,…

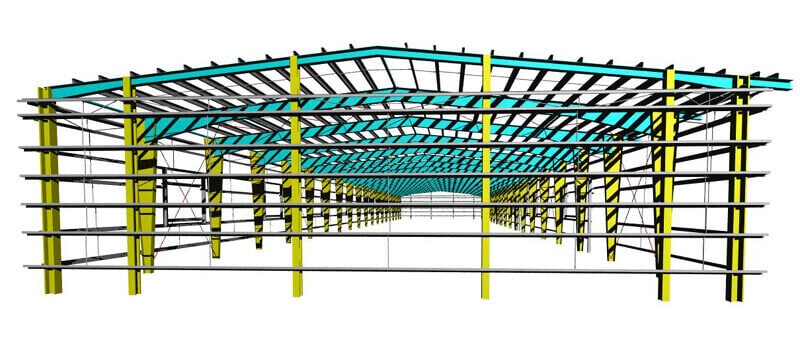

The prefabricated Steel structure warehouse is a storage building with steel structure as the main load-bearing structure. It uses steel as the primary building material, which has the characteristics of lightweight, high strength, strong durability, and fast construction. Steel structure warehouse buildings are widely used in industrial production, commercial logistics, and warehousing and can meet various storage and logistics requirements.

The type of prefabricated Steel structure warehouse

Single-story prefabricated Steel structure warehouse

Single-story prefabricated Steel structure warehouse is the most common type of warehouse. It comprises steel structure frames, wall panels, roof panels, doors, windows, etc. This type of warehouse is suitable for storage needs of all sizes and can be a simple storage shed or a large logistics warehouse.

Multi-story steel structure warehouse

The multi-story prefabricated Steel structure warehouse is extended from a single-story factory building, which can obtain multiple space areas under the same building. The multi-story steel structure factory building suits the high demand of many manufacturing industries to utilize space areas. In addition, the column area of the steel structure is small, which can reduce the use of the indoor regions and increase the usable space.

Cold storage steel warehouse building

Cold storage steel structure warehouse is a kind of warehouse specially used to store refrigerated or frozen goods. This warehouse type usually has refrigeration equipment, insulation materials, isolation doors, and other equipment to maintain a low temperature. The cold storage steel structure warehouse is suitable for storing cold fresh food, medicine, and other goods that must be kept at low temperatures.

Large-span steel structure warehouse

Large-span prefabricated Steel structure warehouse is a kind of giant warehouse that spans hundreds of meters or kilometers. This warehouse type usually uses long-span steel structure trusses, concrete foundations, etc., to support the load-bearing of large-area roofs. This warehouse type suits large-scale manufacturing enterprises, shipping ports, air logistics, etc.

The structural form of prefabricated Steel structure warehouse:

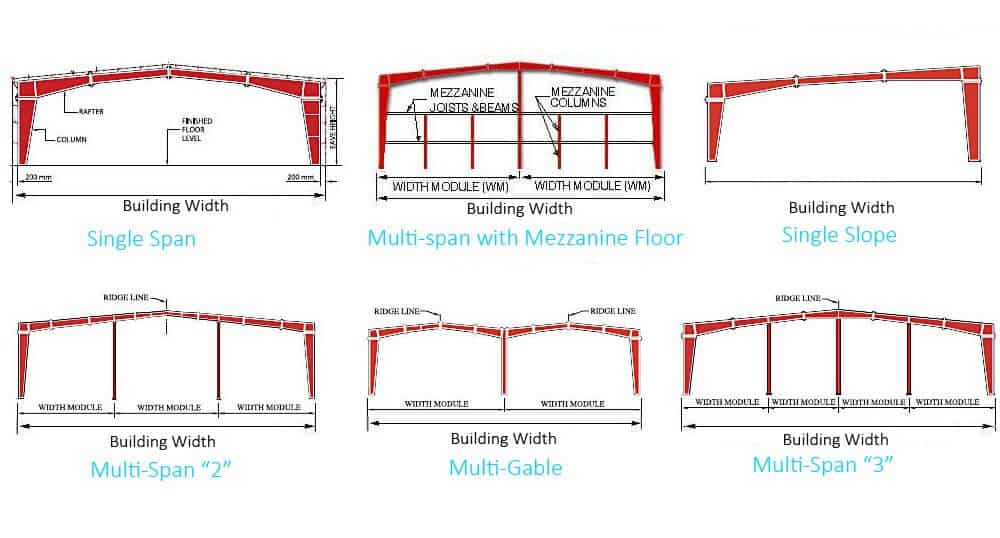

Portal steel frame structure

The portal rigid frame structure mainly comprises columns and beams; the rigid frame is a plane stress system. The bracing between the columns and the roof is set to ensure vertical stability.

Rigid frame

The columns and beams of the rigid frame are made of H-shaped steel, and various loads are transmitted to the foundation through the columns and beams.

Bracing and tie rod

The rigid bracing is made of hot-rolled section steel, generally angle steel. The flexible bracing is round steel. The tie rod is a compressed round steel pipe, which forms a closed force-bearing system with the support.

Roof purlins and wall girt

Generally, it is C-shaped steel and Z-shaped steel. It takes the forces transmitted from the roof and wall panels and transmits them to the columns and beams.

Steel Roof Struss Structure

Common Structural Forms of Steel Roof Trusses:

- Triangle: Economically inefficient, generally used for small-span roofs. To accommodate pitch and shape, the pitch should be greater than or equal to 1/3, and the span should be less than or equal to 21m. Considering the arrangement of purlins, the truss joints are usually spaced 1.5m or 3m apart. The large pitch of the triangle makes the truss equivalent to a variable-section beam. Due to the rapid change in section (truss height), the stress on the chord members is unfavorable, resulting in smaller stress on the chord members in the center and greater stress on the chord members at the ends.

- Trapezoidal: The most commonly used form, often used as the roof structure of industrial buildings. The pitch is between 1/8 and 1/12, suitable for spans up to 36m. The stress distribution is more reasonable than the triangle’s, and the change in the section is relatively stable.

- Chevron-shaped roof truss: Parallel chord members are used at the top and bottom, connected in the middle, and the cross-section in the middle should be smaller than that of the trapezoidal roof truss to save material. The slope of one side of the roof is less than or equal to 1/10, suitable for spans greater than 30m. Three sections can be used when the span exceeds 42m, with a parallel section added in the middle. Corresponding supports should be provided at the fold points outside the plane.

The categories of Warehouse Building:

1. Wholesale warehouse

Wholesale warehouses mainly store commodities imported from procurement and supply warehouses or purchased locally. This warehouse type is generally close to the commodity sales market, and its scale is generally smaller than that of procurement and supply warehouses. It is engaged in wholesale supply, dismantling, and zero supply business.

2. Procurement and supply warehouse

Procurement and supply warehouses are mainly used for centralized storage of commodities purchased from production departments and for international import and export. Generally, such warehouses are located in large and medium-sized cities where commodity production is relatively concentrated or where commodity transportation hubs are located.

3. Processing warehouse

After talking about the function of the warehouse, we have already talked about the processing delay function of the warehouse. Generally, a warehouse with product processing capabilities is called a processing warehouse.

4. Transit warehouse

The transit warehouse is in the middle of the cargo transportation system, storing the goods waiting for transshipment, and the general cargo is only temporarily parked here. This warehouse type is generally set up near the road, railway station, and port terminal for water transportation to facilitate cargo transportation. Awaiting shipment here.

5. Retail Warehouse

Retail warehouses are mainly used for short-term storage for the commercial retail industry, generally for store sales. Retail warehouses are small in scale, and the turnover of stored materials is fast.

6. Reserve warehouse

The state generally sets up such warehouses to keep the country’s emergency reserve materials and combat readiness materials. The storage time of goods in such warehouses is generally relatively long, and the stored materials will be updated regularly to ensure quality materials.

7. Bonded warehouse

Bonded warehouses refer to warehouses set up on the territory of a country for the needs of international trade but outside the customs border. The goods of foreign enterprises can enter and exit such warehouses free of duty and go through customs declaration procedures. After approval, the goods can be processed, stored, and so on in the bonded warehouse.

Advantages of prefabricated Steel structure warehouse:

Space advantage

Enterprises with high requirements for space use choose prefabricated Steel structure warehouse because it can expand the utilization rate of warehouses. Since the compressive and lateral bending strength of steel is 1.5 times that of concrete on average, the section can be reduced under the same strength, thereby increasing the limited use space of the warehouse building.

short construction time

The finished steel components will be transported to the construction site for construction and installation. This “production to construction” mode greatly shortens the construction period and reduces the construction period and labor costs.

Energy saving and environmental protection

The material can be 100% recycled and is green and pollution-free. It adopts high-efficiency energy-saving walls, which have good thermal, heat, and sound insulation effects and can reach 50% energy-saving standards.