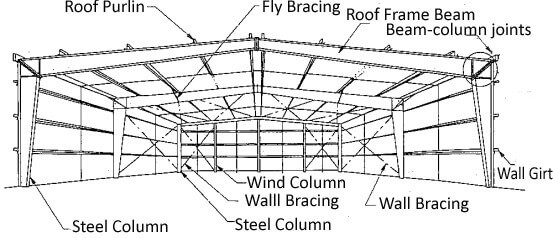

A steel frame is a structure made of steel, usually connected by welding, bolting, or riveting steel beams, columns, bracing,…

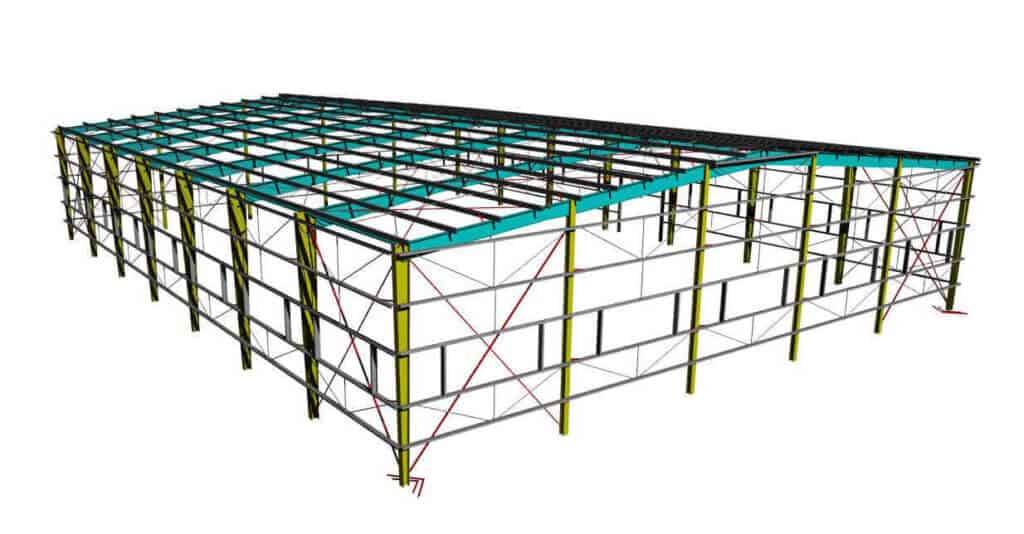

The prefabricated steel building is the main structural form of industrial workshops and other public buildings. It has the advantages of simple structure, short construction period, and reduces the amount of steel used, and has an extensive application prospect.

The prefabricated steel structure is lighter in weight, has sound vibration (seismic) and impact resistance, and is more convenient for assembly and construction. Therefore, the application of prefabricated steel structure in the industrial building is extensive, especially in workshop buildings.

The Conception of Prefabricated Steel Building:

Prefabricated steel structures are affected by traditional wooden frames, and most of them are replaced by thin-wall steel or small-section steel composite trusses. After this, the prefabricated steel building was developed from a single-story structure to a large industrial factory building. It was made of small cross-section angle steel and steel pipe, H-shaped steel, round steel, and profiled steel plate, so it has many advantages and is widely integrated.

The main structural form of a prefabricated steel structure used in industrial construction is the portal steel frame structure system. It distributes channel steel or angle steel through the vertical bracing, making the lateral rigidity and strength increase. A series of disaster resistance properties such as earthquake resistance is greatly enhanced, and the horizontal load is also increased.

The prefabricated steel building has many characteristics, coupled with a simple structure and a single material, can be mass-produced on a large scale, saving costs and labor, and minimizing waste. Lightweight materials, exquisite shapes, extensive use, and mature applications have improved economic benefits and catered to the scientific development concept and environmental protection and energy-saving. Therefore, the distinctive features of prefabricated steel building have become popular among manufacturers and architects.

Design of Prefabricated Steel Building

The foundation of Prefabricated Steel Building

1. Judge the stress point of the foundation.

First, a portal frame model should be established, and then the stress points of the foundation, that is, the load on the steel column, should be judged on the foundation.

In addition to calculating the load on the model, the eccentricity of the eccentric load must be calculated.

The existence of many sizeable mechanical equipment or goods in the factory building will often cause a large amount of accumulated load, which will increase the eccentricity of the foundation. Therefore, the engineer must check it in the design of the foundation.

The lighter self-weight makes the base net reaction force of the light steel structure relatively small. Therefore, the horizontal load caused by wind load cannot be ignored in the design process.

2.Adjust the form of foundation.

Different buildings have various stress points. Therefore, the engineer needs to adjust the foundation form of the building for the stress points according to the actual situation. Take a factory building with more large-scale machinery and equipment as an example. In an existing design, the foundation form of a rigid column foot is often used. However, the factory building will still be offset under external force, and the eccentricity will increase with time. The phenomenon of rising, the foundation form of the building must be adjusted and improved according to the actual situation.

Design of roof and wall structure

In the design process, to increase the stiffness and avoid the instability of the steel frame outside the plane, attention must be paid to the roof and wall construction measures in the light steel structure portal rigid frame factory.

For column distances less than 6m, set one brace. For column spacing greater than 6m, set two braces. The corner bracing of the roof and the wall can prevent the flange plate of the H-shaped steel from buckling due to compression and damage to the portal steel frame.

Purlin design often neglects the stability under the action of wind suction, which leads to easy instability and damage under high wind suction. The attention should be paid to check whether the cross-section of the purlin meets the requirements under the action of wind suction.

Design of the steel mezzanine floor

The steel mezzanine floor is currently more common. Because of its practical and economic characteristics, it has been widely used in the construction industry.

Due to the low stiffness of the steel mezzanine structure, it is necessary to set up bracing to ensure stability and strength. It directly impacts the bearing capacity of the entire building and directly impacts the stability and usability of the building. Therefore, engineers need to have a detailed understanding of the original construction project and determine a scientific and practical design plan. Ensure the rationality of the design.

Features of prefabricated steel structure building:

1. Lightweight

The components of prefabricated steel structures are mostly thin-walled steel, so it is lightweight. Especially for the enclosure system, the weight of the enclosure system, such as corrugated single color sheet and the insulation layer, is only about 8% of that of the reinforced concrete structure. The structure itself has less load and less earthquake action, which can reduce the costs of the foundation.

2. Good mechanical properties, high strength, and large span

From the perspective of the beam height-span ratio, the reinforced concrete structure is generally 1:12, and the steel structure is 1:24, which is double the difference. For light steel structures, the gap is even more apparent.

It is more complicated and uneconomical for the 30m span of reinforced concrete structure, but it is widespread for the steel structure.

3. Short production and construction period

The components of a prefabricated steel building are processed in the factory, and the building materials are finished or semi-finished products and assembled on-site: factory production, on-site construction.

Besides, the factory has high processing accuracy, small dimensional errors, and mostly bolt connections on-site, so the quality is easy to control.

4. Low cost

An important reason for the rapid development of prefabricated steel structures is to save materials.

Compared with traditional reinforced concrete structures, the work efficiency is increased by 1/4 to 1/3. Besides, it also has economical advantages over reinforced concrete structures.

5. Green and environmental protection

Steel is a green and environmentally friendly material. During construction, environmental noise pollution caused by wet concrete work can be avoided, harmful gas emissions can be reduced, and it can be disassembled, recycled, and reused, meeting the requirements of energy conservation and environmental protection