In the construction of modern storage facilities, steel structure warehouses have become one of the mainstream building forms due to…

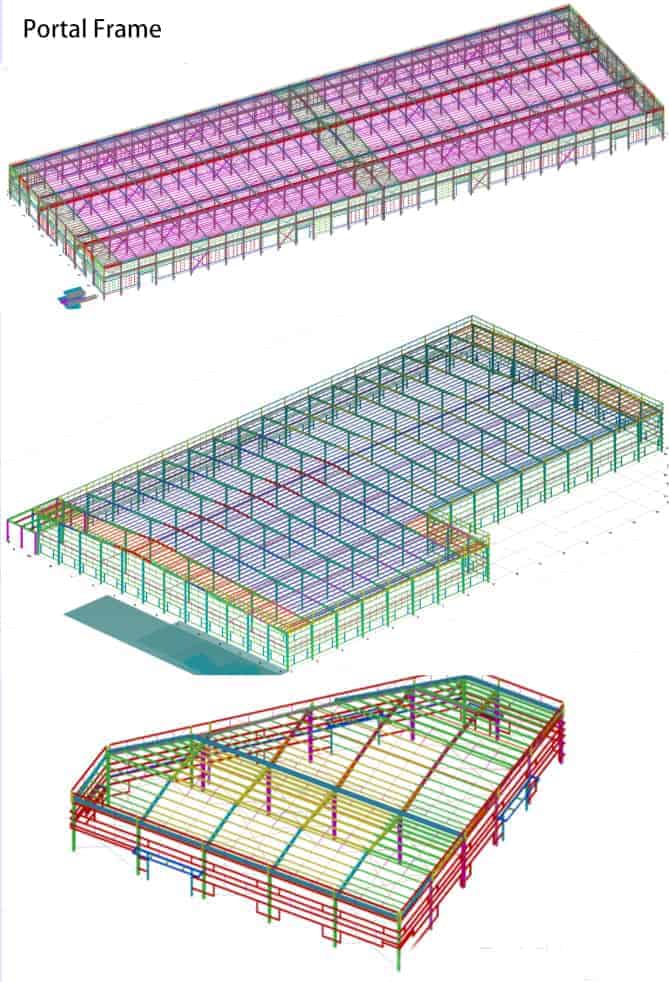

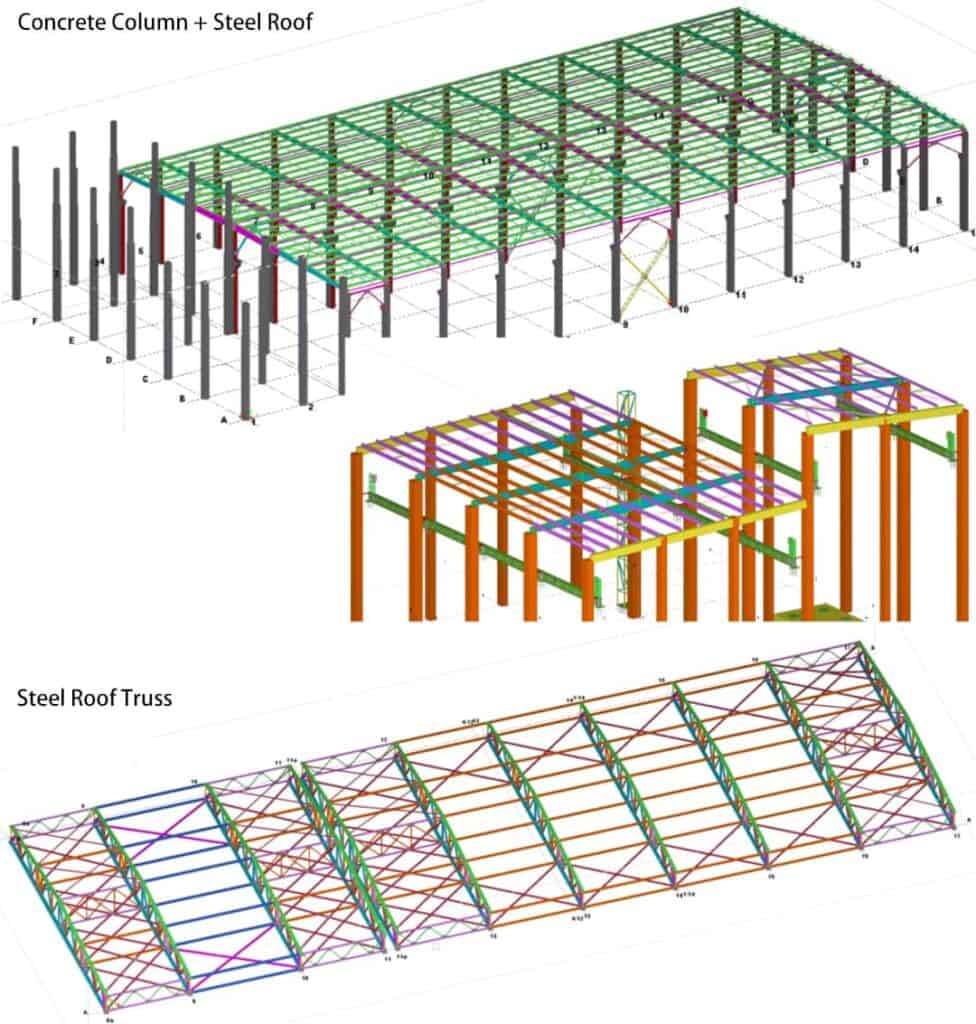

There are many ways to classify building steel structures. According to the structure type, they are portal frame, steel frame, truss, grid, lattice shell, tower, cable-membrane structure, steel-concrete structure, etc. However, in actual projects, they are often classified according to the project’s classification of uses.

Building steel structure classification

1. Building steel structure: Factory buildings

Portal frames are often used, and some also use a combination of concrete columns + steel roof trusses (single-piece trusses or steel beams).

It is characterized by a large span, low steel content, and fast construction speed, and it can be equipped with mezzanines or crane beams according to different usage requirements, making it suitable for factory use.

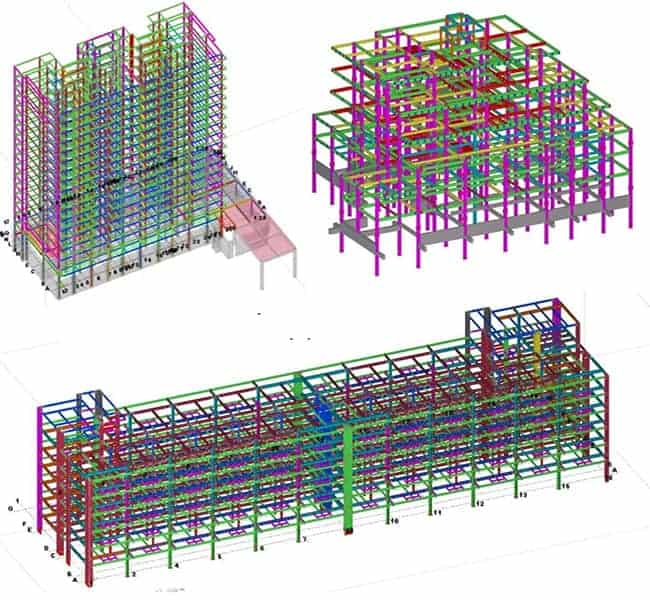

2. Commercial and residential Structure

The primary structure mainly uses steel frames, and multi-story structures use H-shaped steel columns, some with inter-column supports; high-rise or long-span structures mostly use rectangular, round tubes and combined sections as steel columns. Part or all of it is a steel-concrete structure. It is characterized by a flexible bay layout, good structural stability (small deformation), and good load-bearing capacity, making it suitable for commercial and residential use.

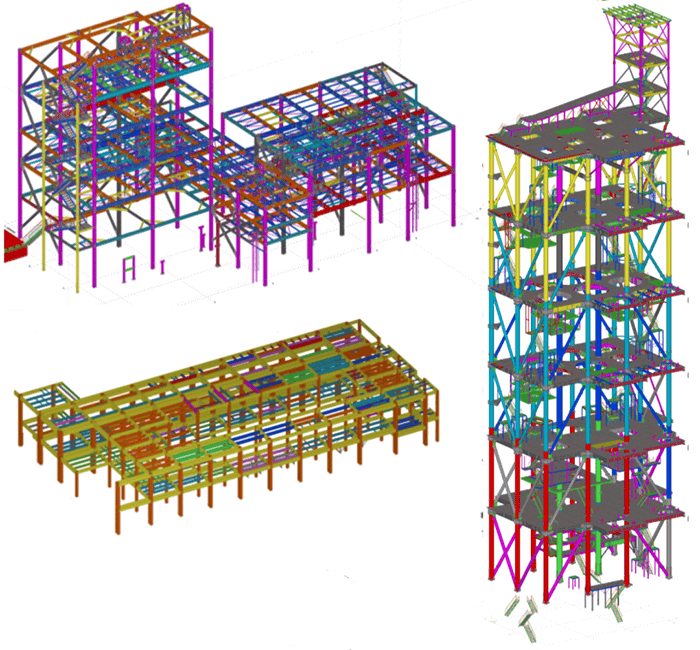

3. Industrial frames:

The primary structure mainly uses steel frames, some of which are integrated with equipment. They are generally equipped with inter-column and horizontal bracing, including equipment bracing, monorail cranes, pattern plates, steel ladders, etc.

It is characterized by primarily mechanical equipment brackets or structures, with staggered structures and numerous cross-section mutations, which facilitate the support and maintenance of process equipment. It is suitable for enterprises with large equipment, such as power plants, chemical plants, steel plants, and offshore platforms.

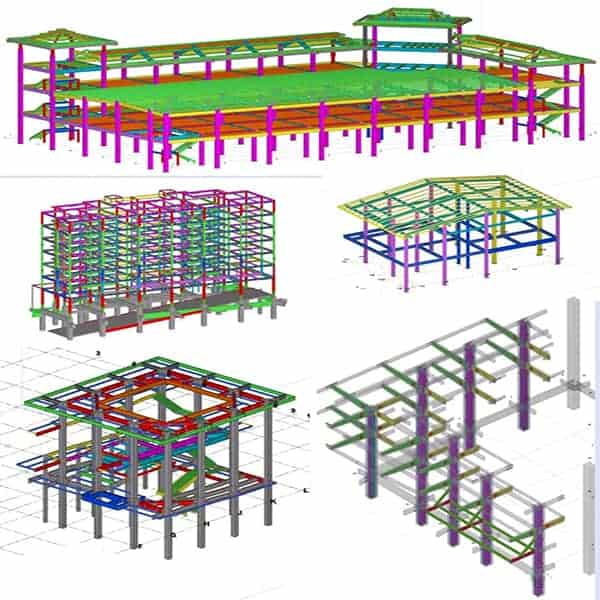

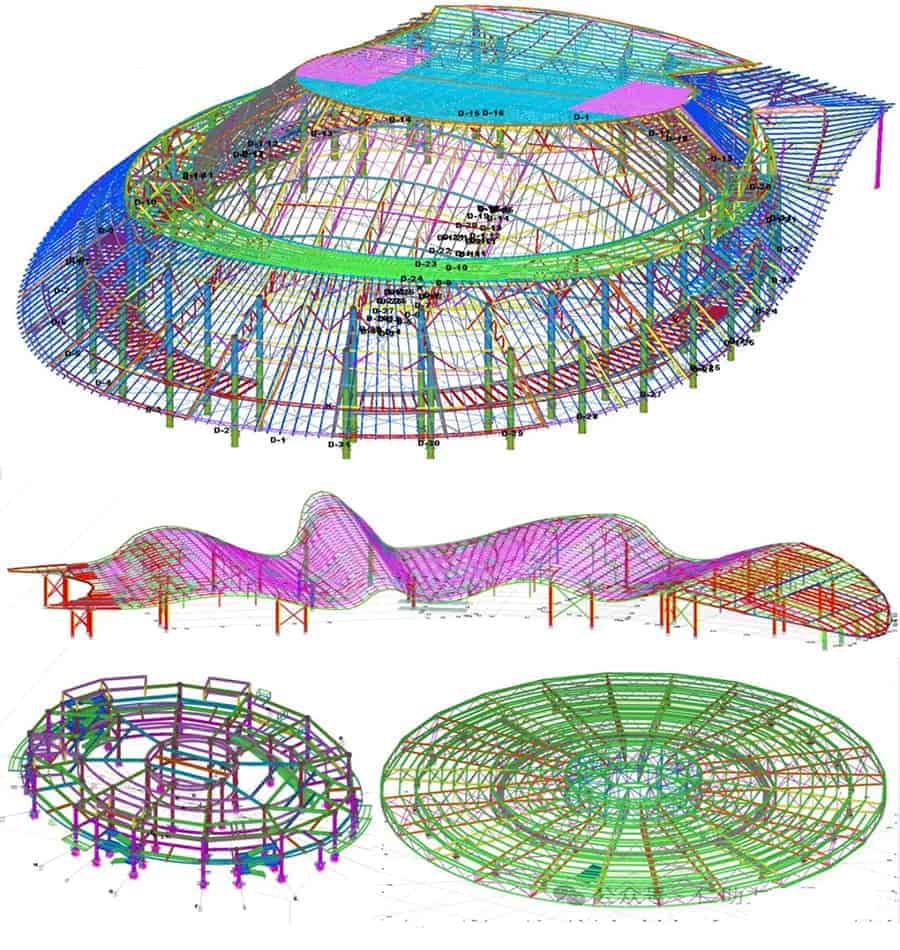

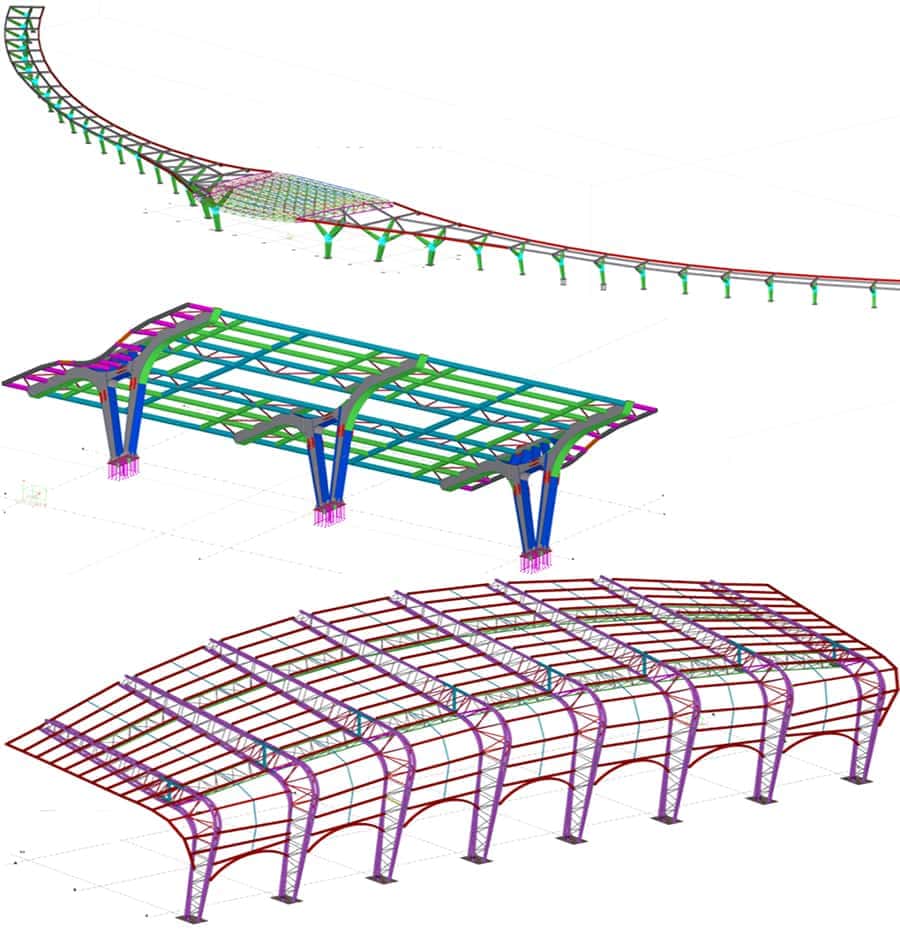

4. Building Steel Structure for the Venue:

The main structure is mostly a hybrid structure, generally including steel frames, trusses, grids, reticulated shells, steel-concrete structures, string beam structures, spiral staircases, hyperbolic beams, etc.; typically, it contains curved surface shapes, including curtain walls, metal roofing, and other enclosure structures.

It has a relatively unique shape, high recognition, and a good connection between various internal functional areas. It suits multiple venues, transportation stations, science and technology, cultural research centers, and other landmark buildings.

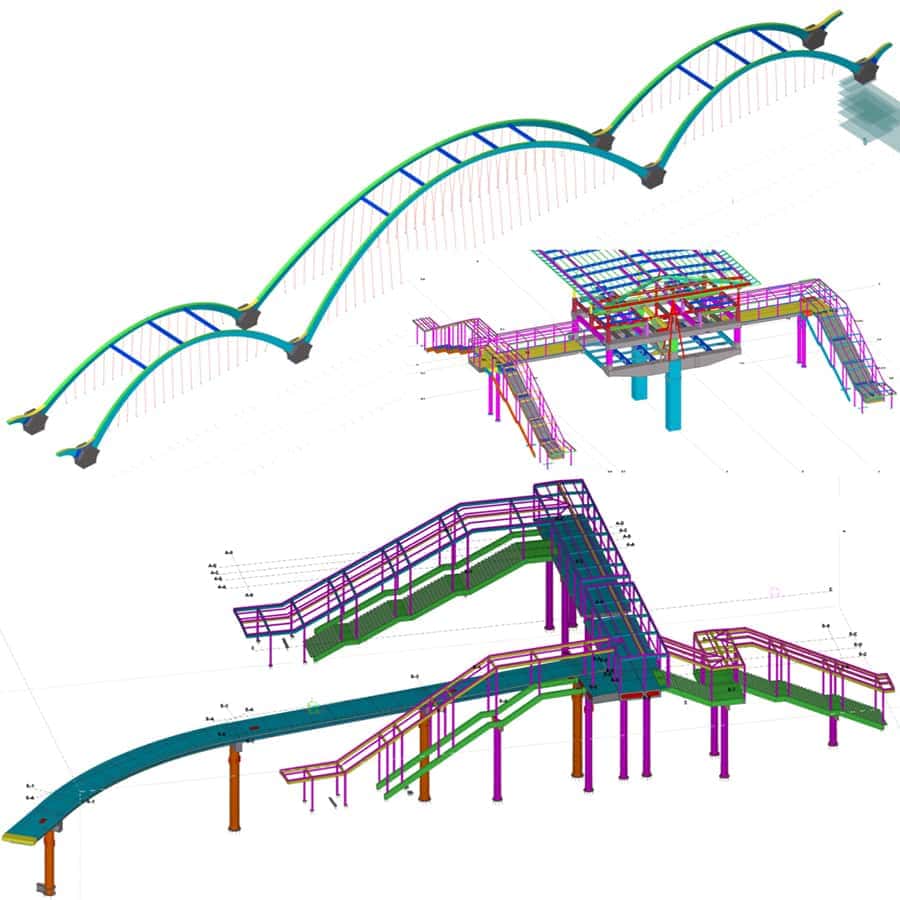

5. Bridges

The main structures are mostly suspension bridges, cable bridges, truss bridges, box bridges, etc., generally curved in the height or horizontal direction. They are characterized by large spans, beautiful structures, a high degree of factory prefabrication, and fast on-site construction. They suit road traffic crossing rivers, valleys, bays, and other natural chasms or line intersections.

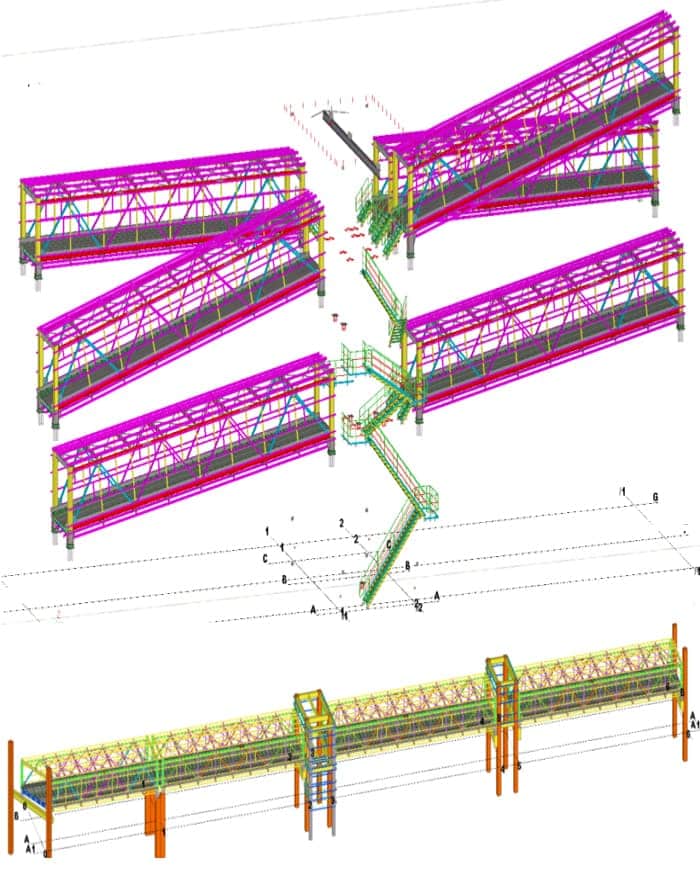

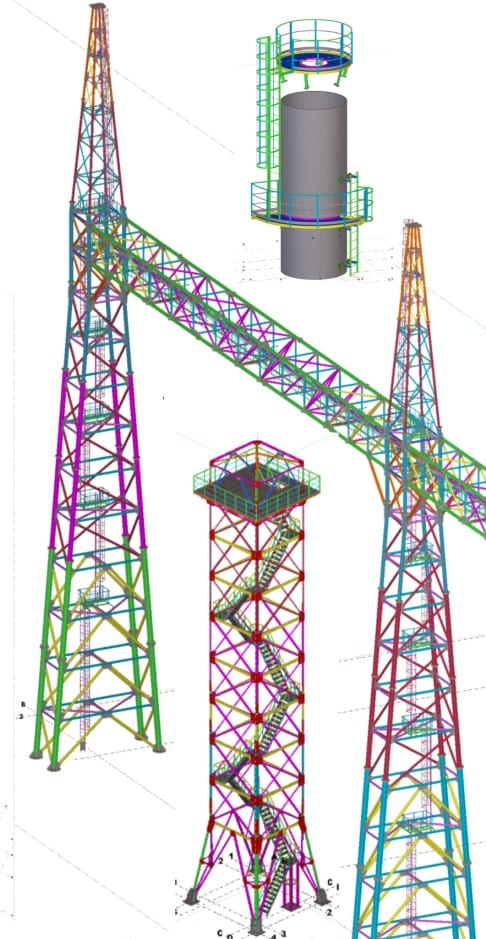

6. Trestle bridges and corridors:

The main structures are trusses or steel frame beams, generally equipped with inter-column and horizontal supports.

Generally, one end of the span direction is set as a sliding hinge support, or a transfer station is set up at a certain distance to release temperature stress structures. The characteristics are that the lines are generally long, overhead, continuous, and have a large span. They are suitable for various scenarios requiring overhead transportation or traffic.

7. Canopies

The main structures are mostly tube trusses, special-shaped steel frames, membrane structures, grids, etc. They are generally open structures, and the steel columns are mostly rigid cantilever columns, usually with curved surface shapes. The characteristic is that the ample lower space does not block the line of sight, and the shape is beautiful. Suitable for use in stadium stands, pedestrian streets, station platforms, and other scenes.

8. Tower Structure:

The main structures are towers, steel tubes, concrete tubes, and generally high-rise structures. The characteristics are that most of the tower rods are bolted, and the construction period is short. Cantilever beams mainly support the external structure of the chimney and require welding, making the construction complex.

Standard towers include transmission towers, monitoring towers, and landscape towers. Common chimney steel structures include inner and outer platforms and stairs.

9. Lighting roof type

The main structure is primarily a grid, lattice shell, supported beam, etc. It is generally a convex steel roof that considers drainage. Both beauty and lighting effects characterize it. It is suitable for use in scenes such as large shopping malls, venues, stations, and other large internal spaces to supplement natural lighting.

10. Scattered steel components:

The main structure is primarily a single truss, cantilever beam, or cantilever column, which generally belongs to the secondary structure. It is suitable for pipe supports, hangers, cable trays, maintenance platforms, etc.

Precautions for the design and construction of building steel structures:

- Reasonably select the type and specification of steel to ensure it has sufficient strength and stability.

- Natural factors such as earthquakes and wind loads must be fully considered to ensure the structure’s safety and stability.

- During construction, key links such as welding quality and node structure must be strictly controlled to ensure the structure’s accuracy and reliability.

- During use, regular maintenance and repairs must be carried out to ensure the integrity and durability of the structure.

Application scope of building steel structure

1. Industrial buildings:

These are used for industrial production workshops (heavy or light steel workshops) and warehouses to store raw materials and finished products. The building steel structure has the advantages of high strength, large span, and high space utilization. It can accommodate various production equipment and meet the process flow.

2. Commercial buildings:

These include office buildings, shopping malls, hotels, and other commercial buildings mainly using architectural steel structures. Steel structures can be designed in different forms and with multiple functions to meet the needs of commercial buildings for flexibility and personalization. Prefabricated in the factory and installed on-site, compared with traditional concrete structures, steel structure commercial buildings can be completed faster and put into commercial operation as planned, increasing commercial value.

3. Residential buildings:

Steel structures are often used in high-rise residences, apartments, villas, and other buildings. They are solid and lightweight, which can reduce structural weight, foundation pressure, and costs.

Residential buildings have high safety requirements, and steel structures have good seismic resistance and can ensure the safety of buildings and residents. Moreover, the building’s steel structure can be recycled to realize the recycling of materials, which meets the requirements of sustainable development of green buildings.

4. Agricultural buildings:

Steel structures are used in buildings for agricultural production, such as greenhouses, chicken coops for farms, pig houses, cattle houses, various storage buildings, and buildings for processing agricultural and livestock products.

Architectural steel structures are widely used and can meet the needs of different types of buildings and structures according to the needs of farmers, ensuring safe and orderly agricultural production.

5. Public buildings:

Including libraries, museums, gymnasiums, stations, airports, schools, and other public buildings. Heavy-duty steel structures are necessary for high structural strength and long service life.

Public buildings mostly use steel frame structures and space structures. Steel frame structures are mainly used in multi-high-rise buildings, such as schools, libraries, and museums. Stations, stadiums, and airports adopt spatial structures to meet the needs of ultra-large spans and ultra-high buildings.

Characteristics of building steel structures

1. Excellent seismic performance

Compared with traditional building structures, steel structures are flexible structures with lighter weight. Therefore, buildings with the same fortification intensity and the same site will bear less seismic force, and the earthquake disaster caused will be correspondingly weakened.

Steel structures should be applied in earthquake areas. The construction will reduce casualties and property losses and have considerable comprehensive benefits.

2. Lightweight and high-strength

Steel structures have the advantages of being high-strength and lightweight, and they can generally reduce a building’s weight by about 1/3. For example, if the strength of steel is G550 and the strength grade of concrete is C25, the strength ratio of the two, for components of the same mass, the bearing capacity of the steel structure is twice that of concrete.

Correspondingly, for components with the same bearing capacity, the weight of steel components is half that of concrete. On the other hand, due to the lightweight and high strength of the steel structure, for a building of the same weight, the steel structure member has a small cross-section and a considerable net height, which can save the building height. The number of layers of the steel structure is more than that of concrete, which not only increases the building area but also increases the height of the building. It has brought good economic benefits.

3. Energy saving and environmental protection

The main body of the building’s steel structure consists of steel components, and the wall material is thermal insulation mortar. This material not only meets the requirements for energy saving but can also be recycled.

It is a green, environmentally friendly, and recycled building that meets the requirements of sustainable development. The thermal resistance value can reach a brick wall thickness of about 1m. Promoting and applying steel structure buildings is the ultimate choice in a country like ours with a large population and energy consumption.

4. The floor plan is flexible, and the effective use area is increased

Steel structures for large spans can be achieved without a large cross-section, which makes the building highly flexible and able to be arranged according to residents’ needs.

This is conducive to meeting the needs of modern homes and adapting to the needs of the modern construction market. Moreover, the steel structure is used, and the cross-sections of beams and columns are smaller, which also increases the usable area of the residents.

5. High degree of industrialization and a short construction period

Building steel structures use steel plates or shaped steel, which is processed into components and then installed. Much of their work is completed in professional factories, with high precision and a short production cycle.

Many bolts are used during installation, which has good assembly performance and dramatically shortens the construction period. This advantage also makes the completed steel structure easy to disassemble, with small losses and convenient recycling.

In conclusion

Building steel structures can achieve the construction industry’s green, ecological, and intelligent development goals. It will become an essential pillar for the sustainable development of the construction industry and even the extensive civil engineering industry.

Building steel structures can not only give full play to the advantages of steel structures such as lightweight, high strength, good seismic performance, short construction period, and high recycling rate. Steel structures can transform buildings from construction sites to factory manufacturing. Steel structures effectively promote the transformation of the construction industry.