The service life of steel structure buildings is more than 50 years. The roof and wall panels of prefabricated steel…

Steel workshop buildings have become a structural system with perfect design, manufacturing, and construction standards.

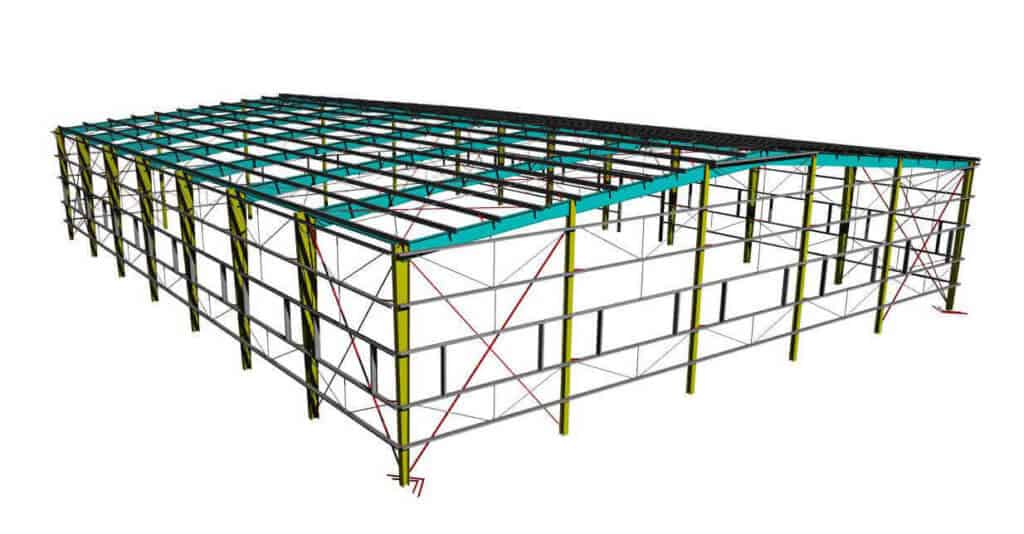

The steel structure workshop is generally a space system. It comprises the roof structure, steel columns, crane beams, brake beams, bracing, and wall girts.

The components of Steel workshop buildings

The horizontal frame of Steel Workshop Buildings

It consists of columns, roof trusses or beams, and bracing connected with the horizontal frame. It is the primary load-bearing system of single-story steel structure workshops. It bears the structure’s weight, wind, snow loads, and vertical and lateral loads of cranes and transmits these loads to the foundation.

Roof structure

The structural system that bears the roof load includes the transverse beams, brackets, middle roof trusses, skylight frames, purlins, etc.

Steel column

Steel columns are the main load-bearing components of steel structure factory buildings. They bear the weight of the factory building and external loads. Steel columns are generally H-shaped steel with high strength, stiffness, and good seismic resistance.

Steel beam

Steel beams are the main components connecting steel columns. They bear the horizontal load and transfer load of the factory building. Steel beams are generally made of H-shaped steel, which is good for stiffness and stability.

Column and beam connectors

The connection between steel columns and beams is essential to a factory building’s steel structure. It ensures the factory building’s overall stability and load-bearing capacity. Connectors generally use reliable bolted or welded connections that have good seismic resistance.

Bracing system

It includes the bracing on the roof structure and between the columns. On the one hand, it forms a vertical frame of the single-story steel structure with columns, crane beams, etc., and carries the vertical-horizontal load; on the other side, it connects the primary load-bearing system by individual plane structures. The overall structure formed a space, thereby ensuring the rigidity and stability necessary for the steel structure of a single-story workshop building.

Crane beam and brake beam

It mainly bears the crane’s vertical and horizontal loads and transmits them to the horizontal and vertical frames.

Wall girt

Withstand the weight and wind load of the wall.

Besides, there are some minor components, such as ladders, walkways, doors, and windows. In some single-story steel workshop buildings, a working platform is also provided due to the requirements of process operation.

The steel structure workshop is the portal steel frame structure with a straightforward force transmission path. All components are produced in the factory and installed directly on the site; no welding is required, so the construction time is short.

Walls and roofs

Walls and roofs are the external coverings of steel structure factories, and their role is to protect the equipment and personnel inside the factory from the external environment. Walls and roofs are generally made of sandwich panels, colored steel plates, and other materials with good thermal insulation and waterproof properties.

In short, the components of the steel workshop buildings are a coordinated whole, and each element plays an indispensable role. During the design and construction process, appropriate components must be selected according to different building requirements and usage environments to ensure the stability and load-bearing capacity of the factory building.

Classification of steel workshop buildings

Classified by the number of layers

Single-story workshop building: This building has only one floor and is mainly used in metallurgy and the heavy and medium-sized machinery industry.

Multi-story factory building: two floors or above, primarily used in food, electronics, precision instrument industries, etc.;

Mixed-level factory buildings: multi-layer and single-layer buildings are mixed in one building and are primarily used in the leading chemical industry factories and thermal power plants.

Sort by span

The span refers to the distance between two columns of pillars in a factory building. The typical span of industrial factories is 6-24 meters, generally a multiple of 3.

The spans of 15-30m are mainly reinforced concrete factories, and the spans of 36m and above are steel structures—mostly factory buildings.

- Small-span factory building: a single-story factory building less than or equal to 12m, mainly made of masonry structure.

- Long-span factory buildings generally refer to reinforced concrete factory buildings with more than 30m span and steel structure factory buildings with more than 60m span.

- A single-span factory building refers to a factory building with only one span; that is, there are two support points in the transverse direction of the factory building.

- Multi-span factory building: It comprises several spans that can be connected to the workshop.

- Vertical and horizontal intersecting factory buildings: It comprises spans in two directions, and the workshops are connected.

Classified by applicable functions

Mechanical processing and manufacturing, heavy industry

Generally, it is required to be single-layer, and there are requirements for the height of the factory building and the load-bearing of the ground. Some industries require driving beams, which can be used to install driving vehicles.

Textile electronic processing category

Double-storey and multi-story factories are sufficient. Considering the convenience of raw materials and goods entering and exiting, 2 tons or more industrial freight elevators are generally required.

Food chemical industry

In addition to the house’s structure, some requirements apply to its supporting facilities, such as environmental protection, fire protection, sewage discharge, etc.

Dust-proof factory building

Relatively high requirements for the production environment

High power distribution plant

They are primarily used in some large-power electromechanical factories.

Special factory building

Customized factories for some particular industries