As the primary building material for steel structure industrial buildings, light steel structures directly affect the stability of the main…

A steel truss structure is one in which rods are hingedly connected at both ends. The truss comprises straight rods and generally has a planar or spatial structure with triangular units. The truss rods mainly bear axial tension or pressure so that the strength of the material can be fully utilized. When the span is large, it can save material compared with solid web beams, reduce self-weight, and Increase stiffness.

Definition of truss structure:

A truss is a support beam structure composed of rods connected by welding, riveting, or bolting.

Why Choose Steel Truss Structure:

The steel truss rods mainly bear tension or pressure, which fully exploits the role of materials, saves materials, and reduces the structure’s weight. Commonly used ones include steel trusses, reinforced concrete trusses, prestressed concrete trusses, wood trusses, steel and wood composite trusses, and steel and concrete composite trusses.

The steel truss rods mainly bear tension or pressure, which fully exploits the role of materials, saves materials, and reduces the structure’s weight. The truss structure is developed based on the grid structure. Compared with the grid structure, it has unique advantages and practicability, and the steel used is also more economical.

The advantages of steel truss:

- The design, production, and installation of steel trusses are simple;

- The truss has many adaptable spans and extensive applications.

Layout method of steel truss design

- The form of the trusses should be based on the requirements of the building, taking into account factors such as roof materials, skylights, purlins, support arrangements, whether the roof trusses and columns are hinged or rigidly connected, and finally, determine the overall dimensions and web rod system.

- The web member system of the truss. The structural stress should be reasonable, and the node structure should be simple and unified. The number of web members is small, and the total length is short. It is advisable to make the lengthy web members under tension and the short web members under compression so that the chord members do not produce a local bending moment. The angle between the oblique web rod and the chord rod should be 35 to 55 degrees.

- Standard web bar systems include herringbone, ascending, and subdivided systems, which reduce the internodal length of the upper chord and increase the height. The herringbone type is the most widely used in roof trusses. The subdivided truss system saves more steel than the structural solution of dense main web rods.

- The setting of truss joints should be based on architectural or technological requirements, equipment hanging, etc., so the load acts on the nodes as much as possible.

- For trusses with larger spans, arching can solve the problem when the deformation deflection exceeds the limit.

- If the span is too large, it must be divided into sections for transportation. A truss with a span less than or equal to 12 m does not need to be segmented; when the span is greater than 12 m but less than 20 m, it can be divided into two segments; when it is greater than or equal to 20 m, it can be divided into multiple segments, but the length of each segment should not exceed 12m; splicing joints, It should be located at 1/3 of the span of the corridor.

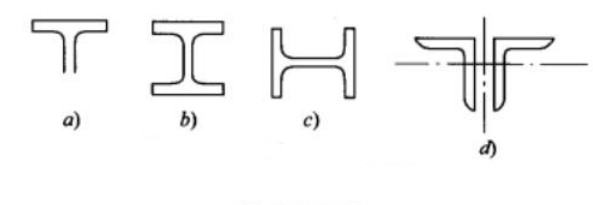

Commonly used cross-sectional forms of steel trusses

When the stress is minor, a double-angle steel section is used. When the component adopts a double-angle steel section and is large (challenging to purchase when ≥160mm), rolled T-shaped steel should be used instead of double-angle steel as the upper and lower chords of the truss. When the load is relatively large, H-shaped steel should be used.

T-shaped and double-angle steel are generally used in industrial buildings, while H-shaped steel is generally used for civil use. H-shaped steel is more convenient to connect to secondary beams. Civil use is usually made of concrete slabs, and the load is generally more significant than that of industrial use.

Application areas of steel truss structures

1. Industrial buildings:

For industrial buildings with large spans, using steel structure trusses can reduce the steel used, meet the requirements of large spans without central columns, and provide a broad space for production and warehousing logistics.

2. Commercial buildings:

Large spaces, broad views, and flexible layouts are usually required in commercial buildings, such as shopping malls, office buildings, hotels, etc. The lightweight design of steel structure trusses allows the building to be more flexible in space planning. At the same time, the truss structure can support large spans, providing a more expansive space for commercial buildings.

3. Sports venues:

Sports venues are another area suitable for steel structure trusses. Large sports venues require adequate space coverage to ensure safety and visibility from spectator seats. Steel structure trusses can easily support large roofs, providing a vast space for sports venues. At the same time, their strength and stability also meet the requirements of large-span design, providing an ideal venue for hosting various sports events.

4. Bridge engineering:

In bridge engineering, steel structure trusses also demonstrate excellent performance. Steel structure truss bridges have the advantages of being lightweight, having high stiffness, and having a short construction period. They are especially suitable for crossing large rivers or deep valleys. Their lightweight design reduces the bridge’s weight while ensuring sufficient strength, providing reliable structural support for the bridge project.

The Installation of the Steel Truss Structure

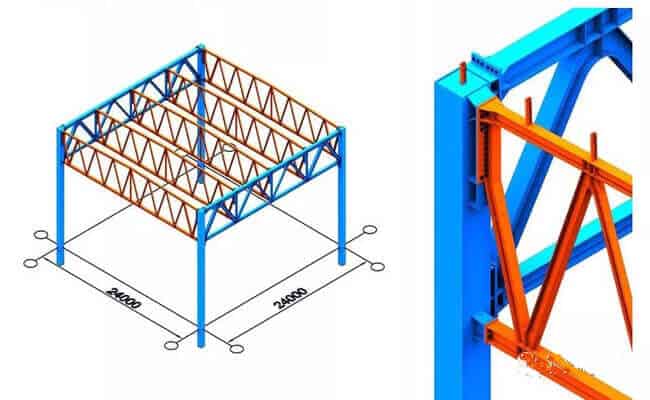

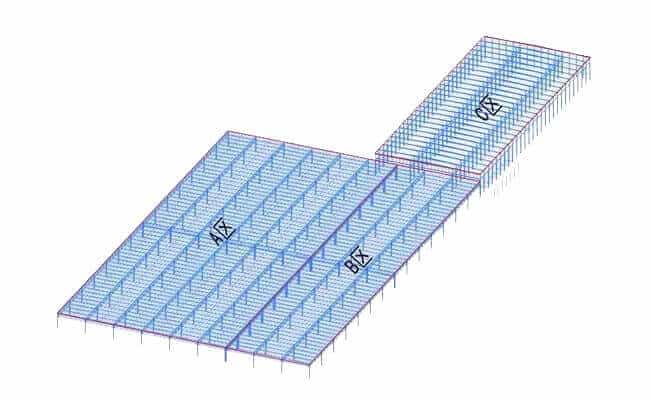

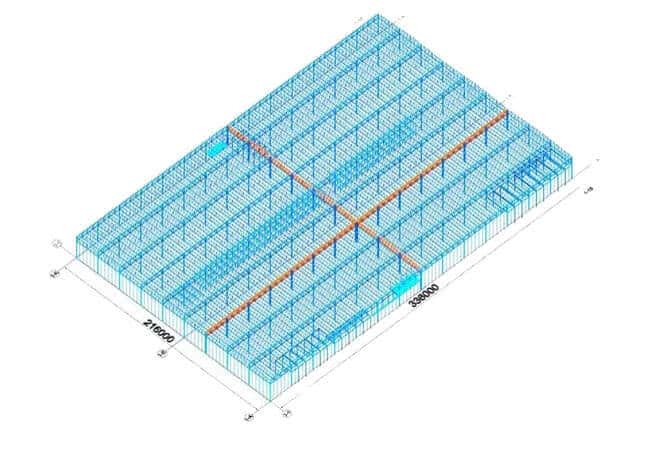

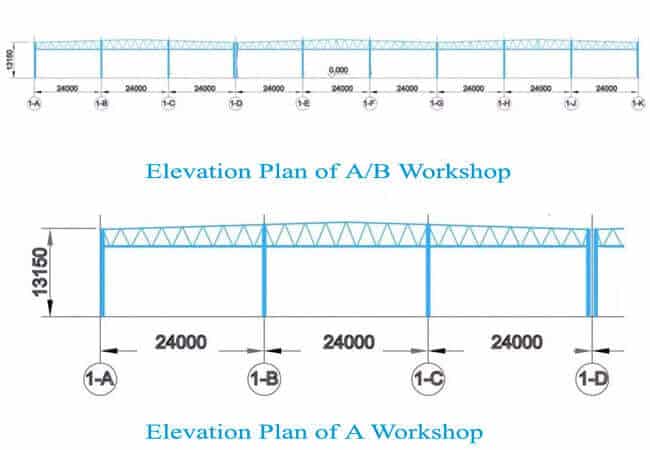

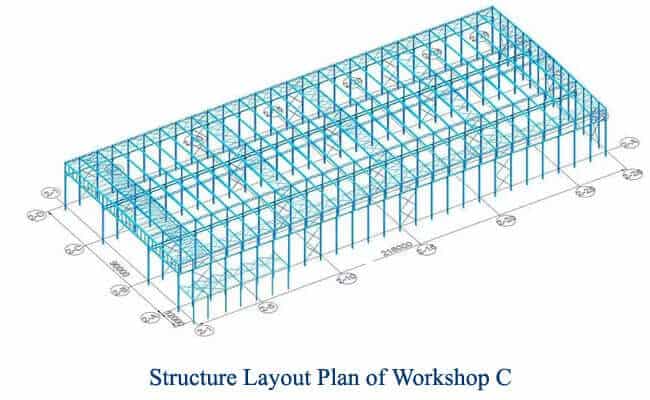

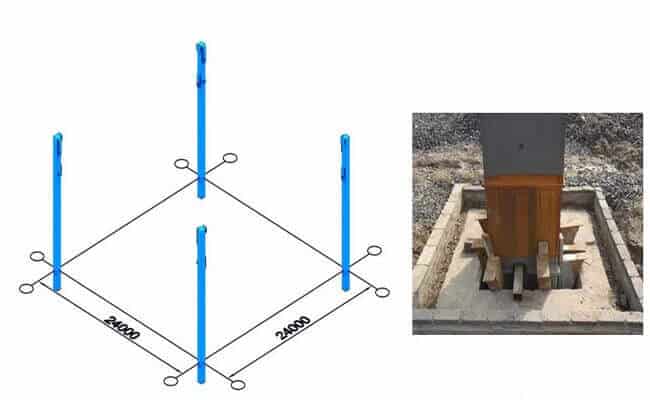

The prefab steel workshop contains a welding workshop in zones A and B and a stamping workshop in zone C. The steel truss structure in Zone A and B is a steel column + steel truss structure with a length of 336 meters, a width of 216 meters, a truss span of 24 meters, and a column spacing of 6 meters.

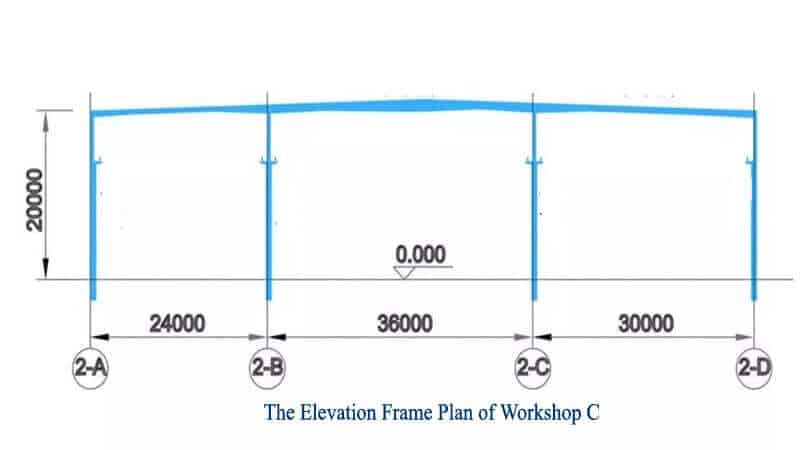

The workshop in Zone C is a three-span portal steel frame structure with a length of 216 meters, a width of 90 meters, and a column spacing of 8 meters. The Span is 24m+36m+30m.

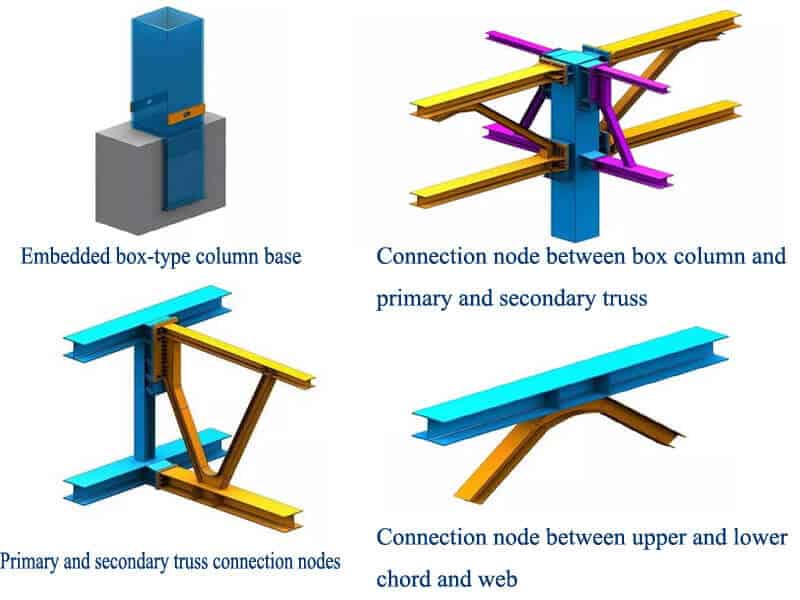

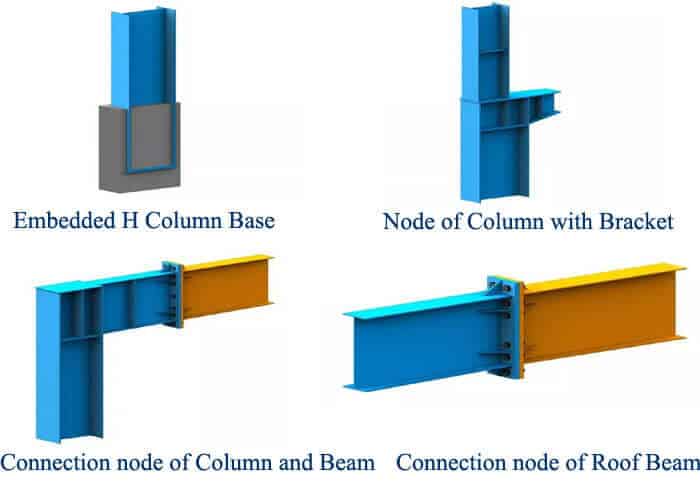

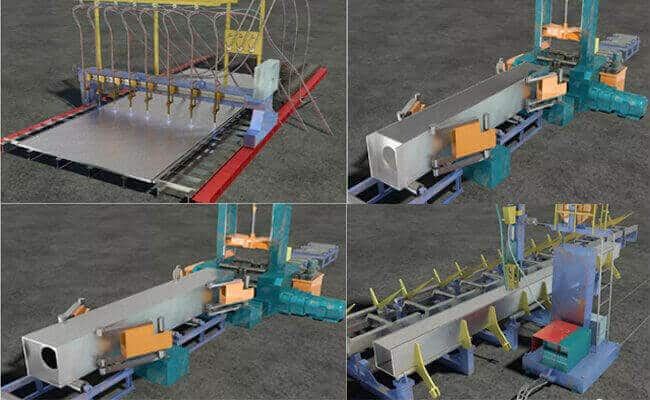

There are 176 box columns with a maximum weight of 8.2 tons. The processing of Steel Box Columns is as follows:

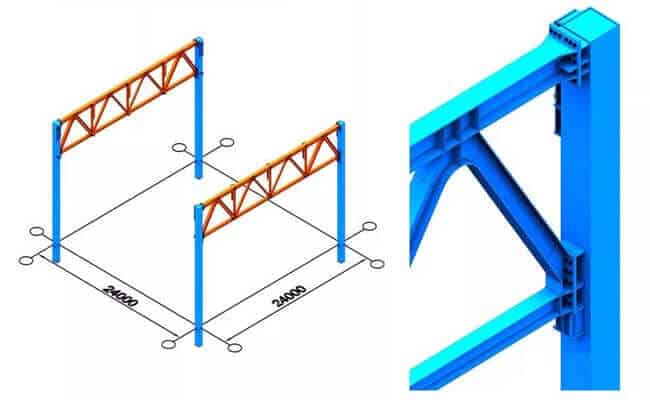

There are 154 main trusses in total. The single truss is 24 meters long and 3.5 meters high. The maximum ceiling height is about 14.1 meters, and the weight is about 12 tons. The main truss chords and web members are all H-shaped steel.

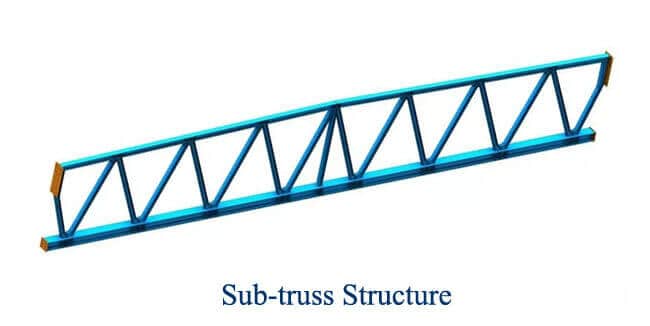

There are 522 sub-trusses in total. The single truss is 24 meters long, 4 meters high, has a maximum ceiling height of 14.1 meters, and weighs about 7.5 tons. The chord and web members of the secondary truss are H-shaped steel.

The installation plan of the Steel Truss Structure:

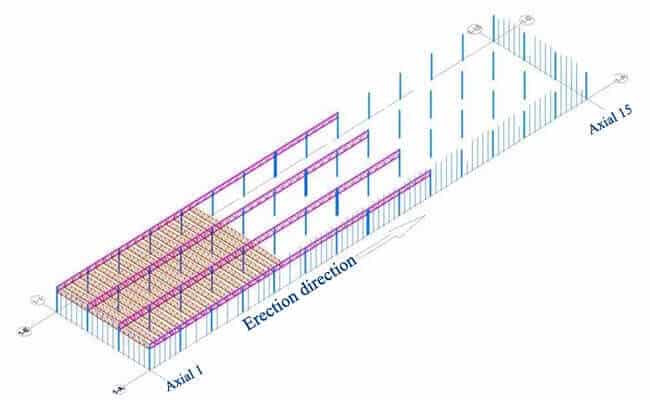

The steel structure building consists of two welding and stamping workshops divided into three zones: A, B, and C. Three areas can be constructed at the same time, saving construction time.

Construction sequence of Steel Truss Structure in A and B area:

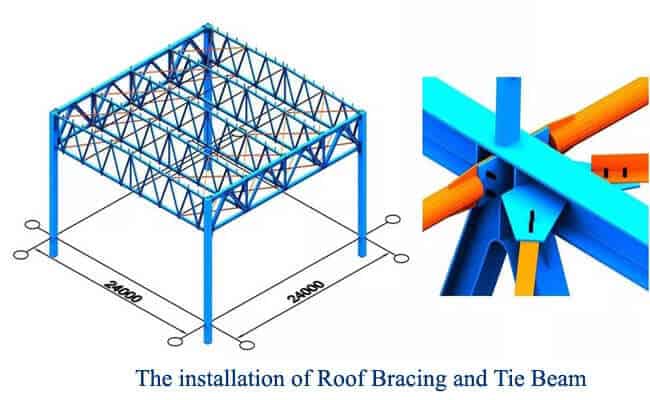

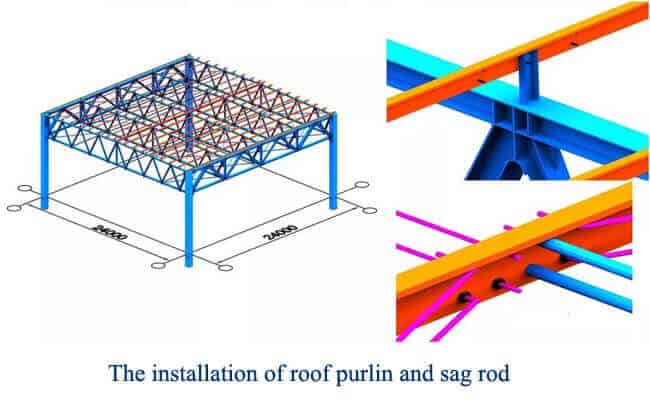

The main process flow of site hoisting construction: steel column → main truss → secondary truss → roof bracing, purlin.

Construction sequence of the steel truss structure in Zone C:

The process of on-site hoisting: hoist steel column → install column bracing → hoist crane beam and correction → roof beam → installation of roof bracing and purlins.

The steel structure in Zone A and B is divided into two construction lines, starting from 1 axis and 15 axes. 4 sets of 25-ton trucks hoist the steel columns, and four sets of 45-ton trucks hoist the main roof truss due to their heavyweight. Four sets of 30-ton truck cranes hoist the roof sub-truss, and the trusses are assembled on-site. The roof trusses are constructed on-site with four sets of 10-ton truck cranes. After the trusses are assembled on the ground, they are directly hoisted in place by 45-ton and 30-ton truck cranes.

Analysis and selection of hoisting machinery in Steel Workshop A and B:

The maximum length of the steel column is about 16 meters, and the maximum weight is about 8.2 tons. A 25-ton truck crane is selected with a boom length of 24.2 meters, a hoisting radius of 8 meters, a height of 21 meters, and a lifting weight of 8.45 tons, which fully meets the lifting requirements.

The length of the roof’s main truss is 24 meters, the height is 3.5 meters, the maximum top elevation is about 14.1 meters, and the weight is about 12 tons. Choose a 45-ton truck crane with a boom length of 25.3 meters, a hoisting radius of 8 meters, a hoisting height of 24 meters, and a lifting weight of 14.8 tons, fully meeting the hoisting requirements.

The single sub-truss length is 24 meters, the height is 4 meters, the maximum ceiling height is about 14.1 meters, and the weight is about 7.5 tons. Choose a 30-ton truck with a boom of 24.4 meters and a hoisting radius of 8 meters. The hoisting height is 24 meters. The weight is 8.55 tons, which fully meets the lifting requirements.