In the construction of modern storage facilities, steel structure warehouses have become one of the mainstream building forms due to…

From garages to workshops to warehouses, steel structure roof is chosen for steel buildings. Not only because it is affordable and durable, almost no need to replace it, but the steel roof also provides a variety of functions and protection to enhance comfort. However, roof panels have various steel types, contours, shapes, thicknesses, and decorative surfaces. Therefore, the designer should select the appropriate variety of roofs based on environmental factors.

When preparing to construct a steel structure building, be sure to consider and select the appropriate roof type and material. If the roof type is correct, the material is suitable, and the installation is correct, the steel structure roof can last for 50 years or more.

Steel Structure Roof Type

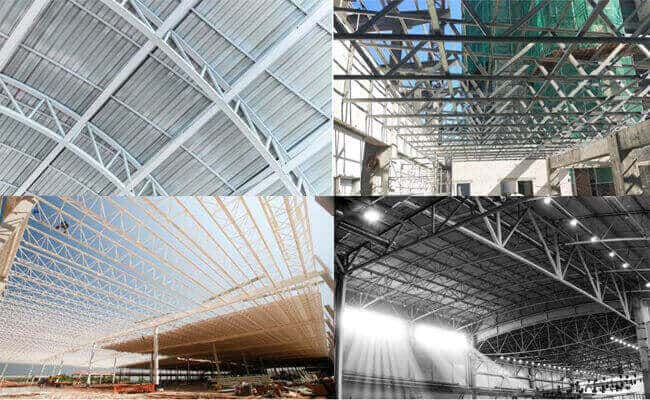

Steel structure roof types are generally divided into three categories: Steel beam structure, truss structure, and grid structure.

The steel roof beam is suitable for buildings with small spans. Hot-rolled sections (I-beam, channel steel, H-beam) are commonly used for small-span beams, and welded I-beams or welded special-shaped steels are used larger-span beams. The vertical parts in the section of these components are called webs, and the vertical and horizontal parts are called flanges. The above beams’ webs are all solid steel plates and for larger spans or large-load beams. Because of their large bending moments, they require a relatively high section to resist. Use solid steel plates. The web is too heavy and inconvenient to produce and transport. Generally, it is suitable for buildings with a small span.

The truss structure refers to the truss beam, which is a latticed beam structure. Truss structures are often used in large-span factories, exhibition halls, stadiums, bridges, and other public buildings. Because it is mostly used in building roof structures, trusses are often called roof trusses. Its web is composed of many small cross-section rods, which is also called an open web (or lattice type) beam.

Grid structure: a spatial structure formed by connecting multiple rods through nodes in a certain grid form. It has the advantages of small space stress, lightweight, high rigidity, and good seismic performance. It can be used as the roof of buildings such as stadiums, theaters, exhibition halls, waiting halls, stadium stands, hangars, and two-way large column spacing workshops. The disadvantage is that the number of rods converging on the node is large, and the production and installation are more complicated than the planar structure.

According to the building type, choose the most suitable steel roof structure.

Steel structure roof needs to consider the following factors:

Meet the local climate conditions

Choosing and installing the right steel structure roof system is an essential thing. For example, in rainy and snowy areas, the snow on the roof will be heavy, which may cause the steel roof design to be unsuitable and will collapse; steel roofs in coastal areas must consider the issues of resistance to wind and better corrosion; in areas with hot weather, steel roofs should be designed with roof panels that accommodate thermal insulation and reflective surfaces.

Appropriate slope

If it frequently rains in the area and there is snow, the design slope should be appropriately larger. In addition, we must pay attention to the installation. For example, if the steel roof is installed with a high slope, the length of the panel will be insufficient; if the installation of the steel roof is low, the length of the panel will be too long. In addition, a steel roof with a high slope will increase labor costs, and construction workers need to move more slowly and carefully, which will take more time to install than a steel roof with a low slope.

You can’t just consider the price

Usually, there are many components for installing steel roof and steel structure buildings, requiring a professional construction team to install and transport. Therefore, the project’s total cost needs to be determined, not just the cost of the steel roof system. At the same time, the lower prices may mean thinner steel, lower corrosion resistance, poorer finish, and service life also will be significantly reduced.

Choose a professional installation team

Due to the different materials of the roof panels, the installation methods will be different, and the construction personnel may have different levels of experience. Experienced installers can complete the installation of the steel roof system faster and better. If inexperienced construction personnel install it, the construction progress will be slow, and the advantages of the short and rapid construction period of the steel structure will not be reflected. If the installer is unprofessional, measurement errors will occur, which will cause rework to increase labor costs, leading to the wrong dimension of the steel components, and reprocessing will increase the cost of materials.

Environmental impact

The roof material, slope, type, contour, shape, thickness, and the decorative surface of the steel should be selected following local environmental factors. For example, there is a lot of rain and high temperature, the slope of the roof cannot be too small, and it is not necessary to use too thick insulation materials. There are little rain and snow in northern my country, and the temperature is low. The roof slope does not need to be too large, but heat preservation must be considered. Roofs in coastal areas should consider the issue of resistance to wind and better corrosion resistance. In hot areas, steel roofs should be designed with roof panels that accommodate thermal insulation and reflective surfaces.

Cost issues of steel structure roof

The complexity of the roofs of different structures is different, and the price cannot be considered. Low unit price means thinner steel, poor corrosion resistance, and a poor finish. Then the maintenance cost will increase, and the service life will be greatly reduced. Besides, there are many steel structure components, and the installation is complicated. It requires professional construction personnel to install it. Otherwise, it will cause unnecessary rework, wrong measurement, or installation, leading to increased reworked material costs and labor costs. Not only will the construction period be delayed, but it will also increase the total cost.

Besides, the material of the roof panel is different; the installation method will be different. Experienced installers will promptly give an effective installation plan to complete the installation of the steel roof faster. They will also promptly discover and solve some installation problems to ensure that the project is completed on schedule.

Roof skylights and ventilation fans

The steel structure roof must consider whether to add skylights and ventilation fan equipment. If they are added later, it will easily cause roof leakage.

A suitable steel structure roof can make the room warm in winter and cool in summer, greatly saving energy costs. A suitable steel structure roof can resist strong typhoons and, at the same time, resist hail damage. The reasonable roof design makes the load capacity of the steel structure roof much stronger than that of other material roofs, making it safer and more stable.

Choosing a suitable steel roof can avoid some troubles in the later period and give full play to the advantages of steel roofs. The steel roof is beneficial in maintaining the indoor temperature. In winter, the steel roof will radiate heat reflected from below back into the engineering building. In summer, the high reflection of the steel roof will deflect heat instead of transferring it to the engineering building. In addition, the enhanced heat reflectivity of the steel roof can reduce the need for heating and cooling, thereby significantly saving energy costs. Most importantly, the steel roof has high safety performance, strong wind resistance and can withstand the damage of typhoons and hail. The load capacity of the steel roof is also much stronger than other materials.