A steel frame is a structure made of steel, usually connected by welding, bolting, or riveting steel beams, columns, bracing,…

Steel structure manufacturers mainly provide integrated services such as design, manufacturing, and construction of steel structure buildings. However, there are significant differences in the scale and operation mode of steel structure companies, and the specific service content that can meet the needs of different customers is also different.

What services can steel structure manufacturers mainly provide?

Small steel structure manufacturers:

Small-scale steel structure manufacturers usually only provide production services for steel structures. After the customer provides the design drawings of the steel components, the steel structure manufacturer fabricates them according to the detailed parameters of the drawings.

Such companies often focus on cost control and are suitable for some simple or standardized engineering needs. The quality of processing is closely related to the equipment configuration of the factory, the sense of responsibility, and the experience of the quality inspectors. If the factory process is strict, the quality control is in place, and it is equipped with experienced quality inspectors, the quality of production and processing can usually be guaranteed. Due to the small scale of production, the processing fee is generally more economical.

Medium and large steel structure manufacturers:

Large-scale steel structure manufacturers usually provide general contracting services for steel structure buildings, involving the entire process of steel structure design, processing, installation, etc.

These companies are equipped with a complete set of steel structure production lines and professional construction teams, and can provide customers with one-stop solutions. Such companies usually have strong technical strength and project management capabilities and can undertake more complex steel structure construction projects.

Due to the large investment in equipment and the high professional level of technical personnel, the overall price is relatively high. Still, the completion quality and construction efficiency of the project are more guaranteed.

Steel structure export:

Some steel building manufacturers have export rights and can provide a series of steel structure related services to overseas customers. Steel structure export not only include steel structure design, production and processing, but also cover packaging, transportation, and after-sales. Experienced and professional steel structure manufacturers have obvious advantages in customer communication, quality control, packaging, transportation, after-sales service, etc., and can provide customers with more efficient and reliable international services.

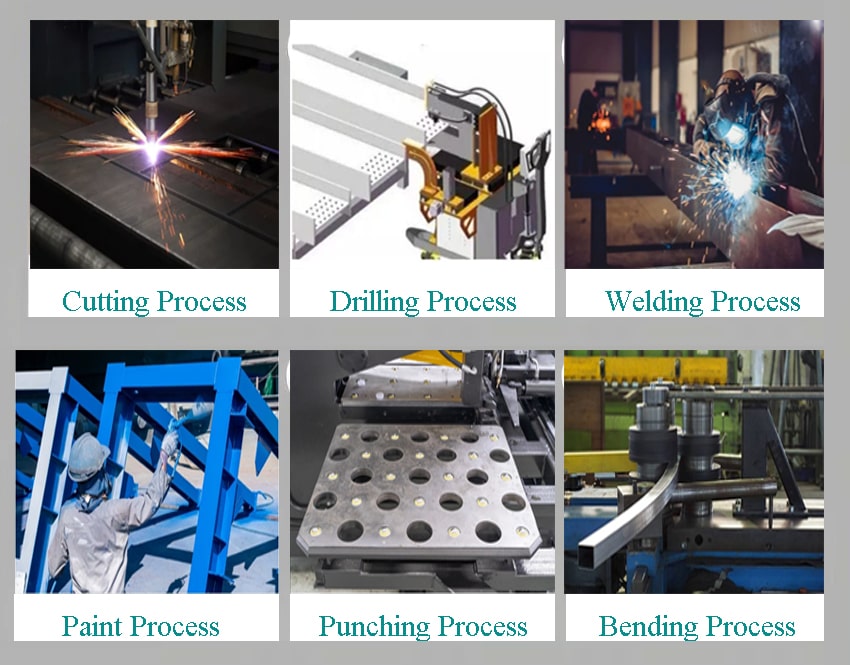

Common processing techniques used by steel structure manufacturers

1. Steel cutting process:

The production of steel structure requires cutting steel according to design requirements to ensure that the shape and size of the components meet the standards. Steel building suppliers usually use a variety of cutting processes, including plasma cutting, oxygen cutting, and laser cutting, to adapt to different types and thicknesses of steel. Each cutting process has its unique advantages and can effectively improve processing accuracy and production efficiency.

2. Drilling process:

In steel structures, many components such as steel columns and steel beams need to be drilled. In order to ensure the accuracy of the hole position, steel building suppliers usually use computer-controlled CNC drilling equipment for processing. This high-precision equipment can effectively improve the accuracy of the hole position and meet the needs of different steel structure connections.

3. Welding process:

Welding is a standard method for steel structure connection. Steel building manufacturers usually use a variety of welding processes, such as arc welding, argon arc welding, submerged arc welding, etc., to ensure welding quality and connection strength. Choosing an appropriate welding method can effectively ensure the stability of the connection part and the safety of long-term use.

Steel spraying process:

In order to protect steel structures from corrosion and oxidation, steel structure processing plants often spray steel components. Spraying processes include painting, zinc spraying and plastic spraying, which can enhance the corrosion resistance of steel surfaces and improve the service life of structures. The choice of spraying process depends on the use environment and anti-corrosion requirements of the structure.

Steel plate punching process:

Steel plate punching process is a widely used process in steel structure fabrication, and is often used to make steel plate connectors, supports, etc. of various shapes. The required holes can be accurately punched on the steel plate for connecting or fixing other components through punching equipment.

Bending process:

Bending process is used to bend steel plates or steel into the required shape, and is usually used to make connectors and supports of various shapes. Through bending equipment, steel can achieve the required shape and angle without destroying its mechanical properties, adapting to different design requirements.

Leveling process:

Leveling process is used to repair deformed steel components, and is often used to correct deformation during processing, transportation or storage. The steel building suppliers uses leveling equipment to reverse bend the steel to ensure that it returns to its original flat state, thereby improving the overall accuracy and stability of the structure.

Flanging process:

Flanging is a processing method for folding the edge of the steel plate, which is usually used to make steel components such as pipes, air ducts, and channel steel. Flanging can enhance the strength of the edge and also help to better connect with other components. It is widely used in construction and industrial equipment.

Complete set of equipment for steel structure fabrication

1. CNC cutting machine

CNC cutting machine is the core equipment in steel structure fabrication and is commonly used in flame, plasma, and laser cutting processes. The equipment is operated by a digital motion control system, combined with a stepper or servo motor driver to achieve precise control of the processing axis. The processing program can be written or imported into the system file and graphics to cut out the required metal shape. The high precision and high efficiency of the CNC cutting machine greatly improve the precision and production efficiency of steel structure processing.

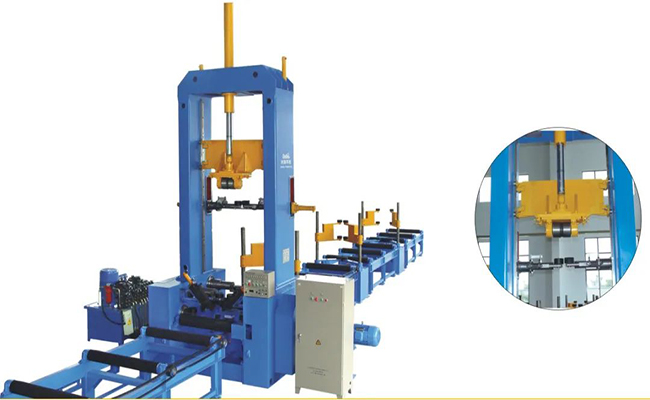

2. H-beam assembly machine

H-beam assembly machine is an indispensable and important equipment in the H-beam assembly process, which can realize the whole process of wing plates and web plates from flat parts to T-shaped and then to H-shaped. The equipment consists of a feeding roller, a main frame, a down-pressure cylinder, a main transmission system, a web and wing plate centering positioning mechanism, a feeding roller and a control system, which can efficiently and accurately complete the assembly of H-beams.

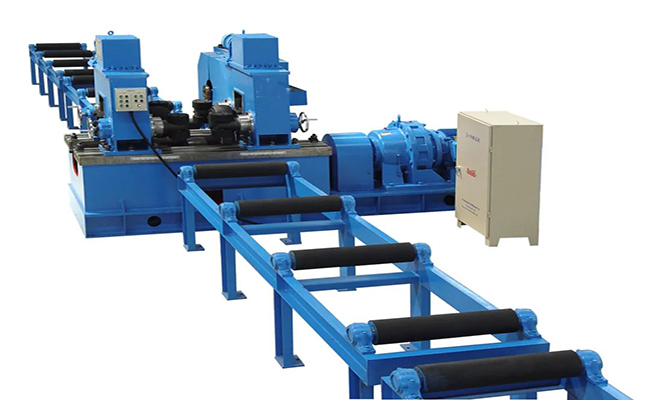

3. Submerged arc welding machine

Automatic submerged arc welding machine is mainly used for submerged arc welding of H-beams, with a high degree of automation and ease of operation. The welding head supports functions such as vertical lifting and angle adjustment to meet different welding needs. The flux is fed by gravity and recovered by the negative pressure vacuum machine, ensuring the rational use of the flux during welding. The two welding heads can work simultaneously or weld independently to ensure welding efficiency and quality.

4. H-beam straightening machine

The H-beam flange straightening machine is a device specially used to correct the deformation of the welded H-beam flange plate. Through this equipment, the warping and deformation of the flange plate caused by the welding process can be effectively corrected to ensure the accuracy and stability of the steel structure and improve the overall quality of the structure.

5. Shot blasting machine

Shot blasting machines are widely used for surface cleaning and strengthening of metal structural parts, H-beams, steel plates and other profiles. By hitting the workpiece surface with high-speed rotating pellets, the shot blasting machine can remove impurities such as surface rust and welding slag, and effectively eliminate welding stress. Shot blasting not only improves the fatigue resistance of the workpiece, but also increases the adhesion of the paint film during painting, thereby improving the overall surface and internal quality and extending the service life of the structural parts.

The main business of steel structure fabricator:

Industrial buildings: including various types of steel structure factories, warehouses, workshops, storage rooms, etc.

Commercial buildings: involving steel structure shopping malls, supermarkets, gymnasiums, garages, office buildings, wholesale markets and other projects.

Agricultural buildings: such as steel structure farms, stables, cattle sheds, pig houses, chicken houses, etc.

Residential buildings: including steel structure villas, apartments, dormitories, etc.

Other building types: such as steel structure hospitals, schools, lofts, corridors, enclosures, stairs, platforms, etc.

In conclusion

steel structure manufacturers can provide diversified services according to the specific needs of customers. They can handle simple steel component processing and offer a full range of building services from design to construction. Large steel structure companies can complete more complex and high-quality engineering projects through complete production lines, professional teams, and rigorous quality management, while steel structure fabricators with international backgrounds can provide high-quality services to global customers.