The service life of steel structure buildings is more than 50 years. The roof and wall panels of prefabricated steel…

The components of the steel structure industrial workshop mainly processed by steel and each part connected through welding, bolts, and rivets to make it an enclosed building structure.

The structural design and material selection of the steel structure workshop is essential to its function.

The Advantages of Steel Structure Industrial Workshop:

1.Large span

The broad span of steel structure is an essential advantage of applying steel structure in the structural design of the workshop buildings.

Manifested explicitly in the following aspects:

Compared with other building materials, the steel structure has the characteristics of flexibility and lightweight. In the construction process of the same material, the steel structure is more convenient to transport and hoist.

Under normal circumstances, the maximum span of the steel structure is no more than 50meter, and the weight is only one-third of the concrete roof truss.

At the same time, with the same beam height, the steel structure is larger than the concrete. Therefore, in the process of arranging the steel structure, it has flexibility and can fundamentally meet the large-span requirements of architectural design.

The steel structure has the characteristics of simple installation and disassembly and a short project period. Under normal circumstances, in the process of steel structure installation, the degree of mechanized production is relatively high. The materials such as beams and roof trusses produced by specialized metal structure factories, so the quality meets the requirements.

At the same time, in the process of on-site operations, the person in charge of the project also needs to strengthen the input of the construction workforce and material resources to ensure the quality of the project and shorten the project period.

2.The Lightweight of Steel Structure Workshop

During the construction of the steel structure industrial workshop, the steel structure is relatively lighter than the traditional concrete structure, which can reduce the bearing pressure of the foundation.

Moreover, the steel structure system can better solve the disadvantages of the low seismic resistance of concrete structures and the cumbersome construction process. The cold-formed thin-walled steel structure is efficient in the residential building construction process, which can increase the corrosion resistance of the building and extend the building’s service life.

3.Improve construction efficiency

Design the industrial workshop building. The factory needs to manufacture steel structure components through high-strength and mechanized production processes, which increases the quality of steel structure materials and the accuracy of the steel structure to a certain extent.

At the same time, transport the steel structure components of the industrial steel workshop to the construction site. In the process of assembling the steel structure on site, the relevant elements of the steel structure need to bolt, and some simple fixing methods used in the fixing process. It can not only reduce the construction period of construction projects, simplify the construction procedures of the metal structure workshop, but also ensure the construction quality and improve the construction efficiency of workshop construction.

4.Good Earthquake Resistance

The toughness and plastic quality of steel structure are high, so it has a better effect in dealing with earthquake disasters, and high-quality earthquake resistance can effectively reduce the damage caused by earthquakes. As for dynamic loads, steel structures also have high quality and are often able to withstand shocks with a magnitude of over eight, so they are popular in many earthquake-prone areas.

Key Points of Steel Structure Industrial Workshop Design

1.Load design of steel workshop building

The load of the steel structure determines the design of the steel building. Therefore, structural engineers need to design the load carefully and ensure the accuracy of the load during the design process. Thereby enhancing the reliability and safety of the steel structure. At the same time, engineers need to consider factors such as weather during the load design process of the steel structure to ensure that the load design of the steel structure industrial workshop meets the relevant requirements.

2.The Design of Steel Column

In the process of designing the columns of industrial steel structure workshops, engineers need to strictly divide the steel structure according to the difference. Most of the time, there are three forms of column structure: cross-section column stepped column, and separated type. However, under normal circumstances, the steel structure design of industrial workshop needs to construct in strict accordance with the key points of steel structure construction.

3.Fire Protection design of Industrial Metal Workshop

In general, if the temperature of the steel structure is above 100°C, the compressive strength of the steel will gradually decrease as the temperature rises, and the change in plasticity will be just the opposite. Once the steel temperature reaches 250°C, the plasticity of the steel is seriously affected. Therefore, designers must carry out a fire protection design for the steel structure workshop building to improve the heat resistance of the steel structure.

4.Earthquake-proof design

The seismic design of steel structures needs to be carried out from the following two aspects:

When the total height of the steel structure workshop is less than 16 meters. The distance between the edge of the building and the two sides of the seismic seam needs to control within a fixed range. It ensures that the building has good compression resistance.

If the overall height of the building is greater than 21 meters. The distance needs to adjust according to the actual needs of the metal industrial workshop building. So as to ensure that the reinforced concrete structure has good earthquake resistance;

On the other hand,

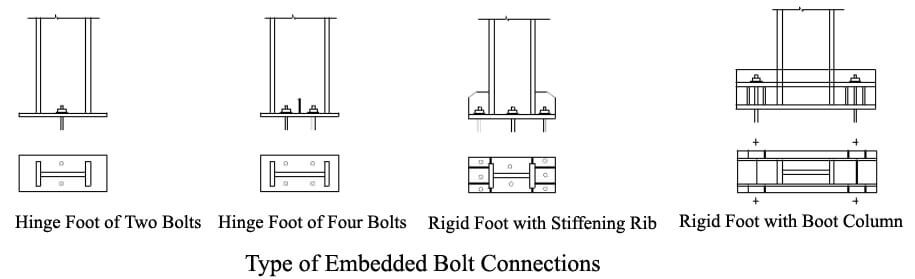

The load-bearing capacity of the steel structure workshop directly limited by the actual situation of the steel column foot. Therefore, structural engineers can use rigid column feet for workshop buildings with greater resistance. The hinged column foot is a kind of light-weight column foot. During the engineering design at this stage, it must be at least twice as high as the section height of the steel column, sometimes even three times.

5.The Design of Bracing

The bracing system is the support frame of the steel structure workshop. When designing, it must consider whether the rigidity of the overall structure meets the standard. Only when the overall strength of the steel structure meets the rule, the space work of the metal workshop can carry out in an orderly manner, while effectively improving the whole steel structure stability.

When designing the bracing system, we must first carefully analyze the internal structure of the factory building. Therefore, on this basis, ensure that the height of the factory building meets the requirements. It is also necessary to ensure the stability of the bracing system between columns and the horizontal bracing of the building.

At the same time, to provide the longitudinal height of the steel structure industrial workshop, two lower columns bracing required to prevent the temperature from damaging the bracing system.

6.The Process Design of Steel Structure Workshop

In the process design of steel structure, it is necessary to fully consider the construction conditions and the specific situation of the enterprise. It is selecting the appropriate mechanism design according to the particular case of the enterprise to ensure that the light steel, frame, cable membrane, and other aspects of the steel structure set reasonably.

If the suspended load used, then when selecting the bracing structure, the engineer must select the construction materials of the workshop that to meet the usage requirements while taking into account the specific work standards and carry out the process design in the steel structure industrial workshop.

7.Anti-corrosion Design

The anti-corrosion design of the prefab steel workshop needs to carried out from the following aspects:

First, it is necessary to improve the anti-corrosion awareness of industrial workshops and strengthen anti-corrosion construction during the construction process.

Secondly, it is necessary to find out the cause of the corrosion phenomenon and formulate targeted anti-corrosion measures according to the specific purpose of the corrosion. It uses to increase the corrosion resistance of the steel structure industrial workshop.

Finally, the steel structure workshop coated with a layer of anti-corrosion protective layer. At the same time, the protective layer also needs to have good hydrophobicity, adhesion, and high electrical resistance. To ensure that it can resist water vapor in the air, oxygen, chloride ions, and other substances will not affect it. And ensuring that it can exert its anti-corrosion effect.