In the construction of modern storage facilities, steel structure warehouses have become one of the mainstream building forms due to…

With the advancement of science and technology, especially metallurgical technology, and the emergence of new building materials and high-strength weather-resistant building steel, steel structure design drawing has received more and more attention in building structures. Steel structure optimization is also playing an increasingly important role throughout the building.

Today, most newly built warehouse or workshop buildings generally adopt portal frames or truss structures; many shopping malls and supermarkets choose steel frame structures; In construction projects with large spans and large spaces, steel structure grids or space trusses are mainly used. In addition, steel-concrete facilities are also widely used in high-rise and super-high-rise buildings. Undoubtedly, steel structure has become one of the main trends in building systems in the 21st century, and careful design is an indispensable key element.

Regulations in steel structure design drawing

General regulations for steel structure drawing:

Steel structure design drawing is divided into structural design, detail fabrication, and construction drawing. The design drawings are completed by design institutes or steel structure manufacturers with design qualifications.

Contents of steel structure design drawings:

Design Description:

Design basis, load data, data item categories, project overview, steel grades and quality grades used, connector models, specifications, weld quality grades, end face planing and top tight parts, rust removal grades, anti-corrosion and fire prevention measures, construction specifications and precautions that should be followed during construction.

When necessary, the design description shall also include the absolute elevation value corresponding to the design elevation of 0.000, the units of the height and dimensions in the drawings, the safety level and design service life of the structure, the seismic fortification category, and the seismic fortification intensity.

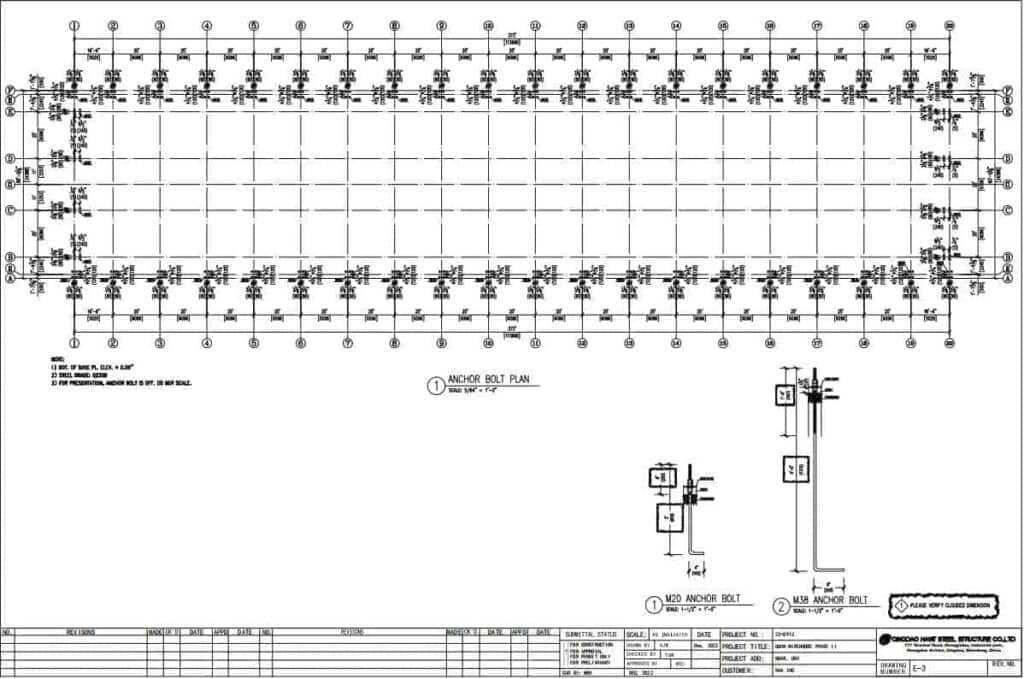

Column Layout Plan

The plan layout of the steel column foot should express the connection structure between the steel column foot and the foundation. The anchor bolt or the column foot foundation layout plan shall be drawn if necessary.

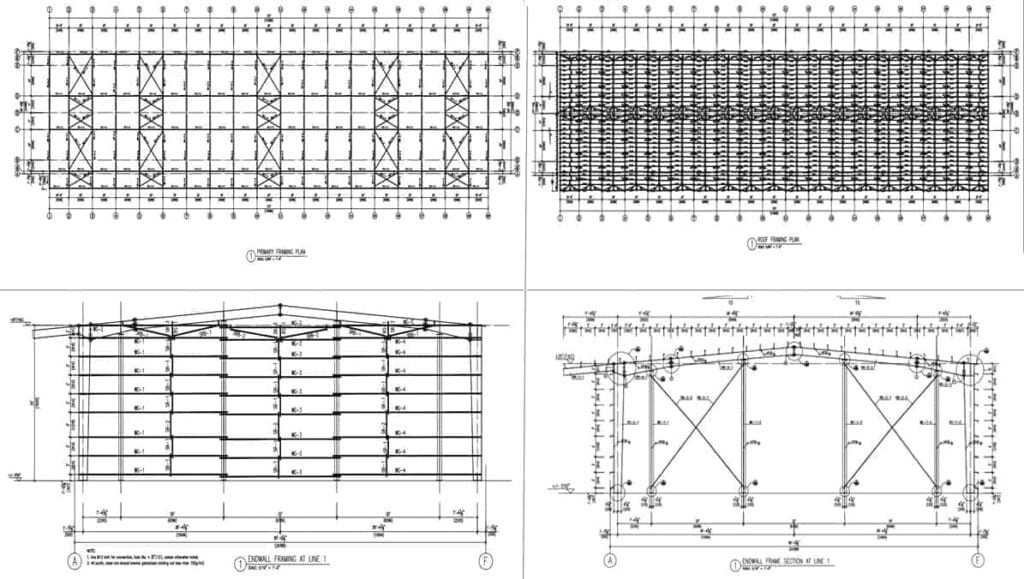

Structural plan

The structural plan should indicate the positioning relationship, elevation, position, number of components, index number of joint details, etc.; if necessary, the layout and critical section drawings of purlins and wall girt should be drawn.

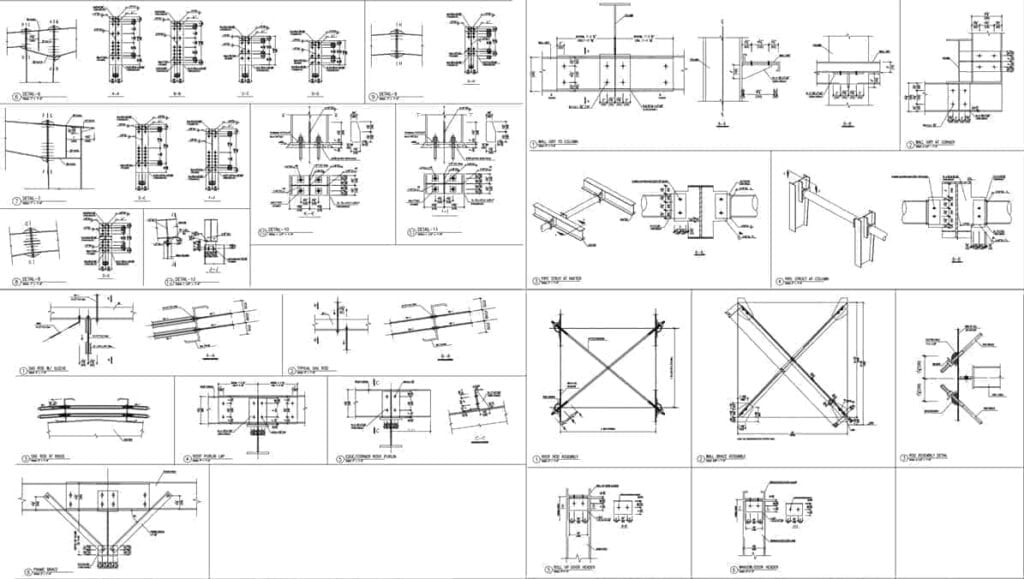

Detailed drawings of components and joints

Steel beams and columns can be represented by unified detailed drawings and tabulations, indicating the steel grades, dimensions, specifications, methods of stiffeners, drawing of connecting joints, and construction and installation requirements.

Steel structure detail fabrication drawing

According to the steel structure design drawing, prepare the enlarged plan of each part that constitutes the structural member, standard detail size, material requirements, processing accuracy, construction process requirements, welding quality level, etc., and number the parts; and consider the transportation and installation capabilities to determine segmentation and assembly nodes of components.

General provisions of steel structure calculation

For structural calculations that are calculated by hand, a sketch of the layout of the components and a sketch of the analysis should be given; the content of the structural calculation should be complete and transparent, the calculation steps should be clear and orderly, the quoted data should have a reliable basis, and the calculation charts and other Commonly used calculation formulas should indicate the source. The component numbers and calculation results should be consistent with the drawings.

When computer programs are used for calculation, the name, code, version, and compilation unit of the calculation program used shall be indicated in the calculation book. The calculation program must be validly approved, and the computer calculation results shall be analyzed and approved; the overall input information, Calculation model, geometry diagram, load diagram, and result output should be organized into a book.

When using structural standard drawings or reused drawings, it is advisable to carry out necessary accounting work according to the description of the atlas and in combination with specific projects, and it should be included in the steel structure calculation book.

All calculation books shall be reviewed, and the design, proofreading, and reviewers shall sign on the cover of the calculation books and file them as technical documents.

Suggestions on Design Drawings

Steel structure design drawing is divided into structural layouts, sections, and node plans.

Layout Plan

The structural layout plan mainly expresses the plane layout of the steel structural components, including the plane positioning relationship of the steel structural components, the section and internal force of the steel structural components, etc., and the numbers, the component section, and internal force are expressed in the component section and internal force table. The structural layout diagram describes the plane positioning relationship of the structural components, the number of structural elements, etc. Structural sectional drawing mainly expresses steel structural members’ cross-section and internal force. Component and node details especially describe the detailed connection structure between components.

Sectional plan

The principle is to clearly express the layout, positioning relationship, elevation, and other information of the structural components in the section diagram; the positioning dimensions of the structural elements should be given according to the primary and secondary levels of the members, and the positioning dimensions of essential equipment should be provided separately and represented by a single line.

Node Plan

The node plan is a detailed expression of the continuous structure between the component connection or the steel component and the concrete. It should genuinely show the actual situation of the component connection, and the steel component should be drawn visually in proportion. For the case of many forms of column foot, it is necessary to give the plan layout of the column foot anchor bolt or the plan layout of the steel column foot foundation.

Specific factors to be considered in steel structure design

On the premise of ensuring the safety and reliability of the structure, implement the merger of functions; that is, one component undertakes multiple tasks at the same time, taking into account the spatial role of the system. For example, roof purlins can also be used as tie rods supported by the roof, and roof purlins can be used as support beams for the lower chord brace of the roof truss, etc.

Make full use of the strength potential of steel. Using more tension and less compression members and minimizing their calculated length is advisable. Thin-walled member structures, such as thin-walled square steel pipe structures for skylight frames and light roof trusses, can be considered lightweight.

Avoid forming stress concentration phenomenon. Structures working under low-temperature conditions or directly bearing mechanical loads are susceptible to the adverse effects of stress concentration, which is often the root cause of brittle failure. Therefore, corresponding measures should be taken in the design to reduce the stress concentration phenomenon. For example, steel with excellent performance can be used to avoid sudden changes in sections, irregular slots, and concave corners.

Establish the concept of equal strength design. The bearing capacity of each member and the connections that make up the structure should be compatible with the bearing capacity of the entire system to avoid weak links.

The open section of the pipe should be closed to prevent corrosion inside and increase its local rigidity.

Steel structure design should consider construction factors.

The steel structure design is a comprehensive process, and construction is the final link in the realization of design products, so construction factors should be considered in the design. In particular, it is necessary to consider the on-site installation workload of steel structure buildings, and the quality of on-site installation directly affects the design quality.

1. Easy-to-connect structure

When determining the structural form, the convenience and possibility of manufacture should be considered, and a structural constitution that is convenient for connection and reliable should be adopted. The installation and harmony of the structure should adopt a structural form that is reliable in force transmission, easy to manufacture, simple in connection, easy to fix, and easy to adjust.

2. Minimize component numbers and material specifications to facilitate material ordering and organize production while increasing material utilization.

3. To be conducive to the force bearing, the shape of the connecting plate should be standardized to facilitate cutting.

4. Try to avoid hot-worked parts.

Thermal processing is labor-intensive, and thermal processing damages the properties of the steel and makes it difficult to control the processing quality.

5. Arrange welds reasonably.

The layout of the welds should be symmetrical to the center of gravity of the components as far as possible so that the force is reasonable and the welding deformation and welding stress can be reduced; the layout of the welds on site should be convenient for component installation, welding of the welds, and quality inspection; avoid three-dimensional intersection of the welds and concentrate a large number of welds in one place. For angle steel sections, the tip of the angle steel leg is to have a different fillet size than the back of the leg.

6. To meet the limit requirements of manufacturing operations.

7. When welding is used for installation and connection, the components should be fixed with bolts and then welded, which is convenient for installation and clamping to ensure welding quality. There should not be less than two mounting bolts for a node.

8. To ensure a safe and reliable connection, use a smaller solder leg size and longer weld length to reduce the weld volume.

9. For columns with more significant stress, the end should be planned and tightened to reduce the weld leg size of the weld.

10. As for the component that uses the support to transmit the reaction force, the thickness of the support plate should have a margin to prevent deviation.

11. The arrangement of supports shall be able to ensure stability between components during installation. Otherwise, it shall be stipulated in the design documents that necessary temporary bracing shall be set during installation.

Characteristics of steel structure

1. The steel structure is uniform in material and is an ideal elastic-plastic material.

The actual stress state of the steel structure is relatively consistent with the calculation results of engineering mechanics so that the steel structure can be reliably and optimally designed.

2. The building material has high strength, and the steel structure is light in weight.

Therefore, steel structural members can be manufactured in factories without being restricted by site conditions and conveniently installed on-site when conditions permit. At the same time, the strength of building steel is high, and the steel structure is light in weight, which makes the steel structure more adaptable and can be used to build high-rise or long-span buildings.

3. Structural steel has good plasticity and toughness.

Therefore, steel structure design should make reasonable use of the plasticity and toughness of steel so that the steel structure has excellent seismic performance and fatigue resistance.

4. The corrosion resistance of steel structures is poor.

Therefore, the steel structure must be protected, and the general protective measure is to paint the surface of the steel structure with anti-corrosion paint. Before painting the color, the surface of the steel structure should be thoroughly dusted. The quality of rust removal directly affects the anticorrosion effect of the steel structure, so the determination of the rust removal level must be appropriate.

5. The steel structure is not fire-resistant.

Therefore, the steel structure subject to high-temperature radiation must be protected, and heat insulation measures shall be taken; for the steel structure with fire protection requirements, fire prevention measures shall be taken according to regulations. Only by knowing and understanding the characteristics of steel structures can we give full play to its advantages and overcome its shortcomings in design. It is one-sided to think that as long as a steel structure, it is reliable and performs well.