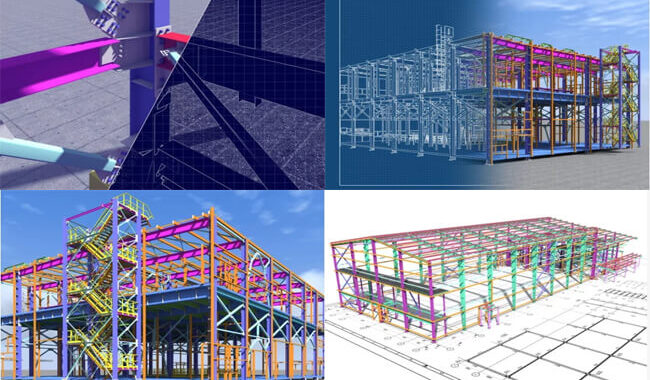

What are steel structure fabrication drawings? Steel structure fabrication drawings, also known as processing details, refer to technical documents that…

With the rapid development of industrial construction, prefab steel building kits have been widely used. Steel building kits and structures have significant advantages: lightweight, high strength, large span, and environmental protection.

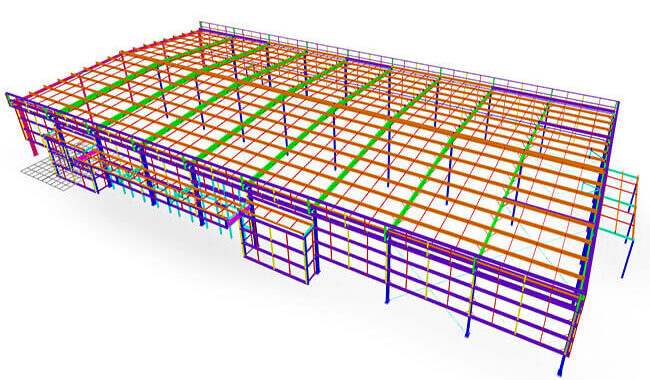

Prefab Steel building kits are mainly composed of horizontal and vertical structure systems. The horizontal structural system is based on the portal steel frame, including roof trusses, beams, and columns as the basic load-bearing structure, which bears roof loads, lateral wind loads, and earthquakes, as well as vertical loads and lateral horizontal loads of cranes. The vertical structural system comprises columns, inter-column supports, wall beams, etc. In addition, there are wall frames and roof supports around the house, which together form a rigid spatial skeleton.

A complete Prefab Steel Building Kits consist of systems with different functions:

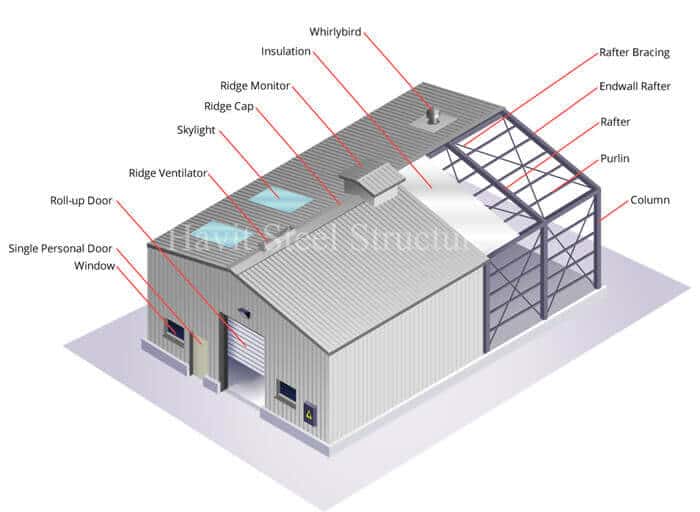

Structural Steel: including the main structure, secondary structure, roof purlins, wall beams, and fasteners.

Wall and roof panel: including roof panel enclosure, wall panel enclosure, wrapping, and floor deck

Door and window: including doors and windows

Ventilation system: including air tower system, exhaust system

Drainage system: including gutters, downspouts, awning systems

Structure system:

1. Main structural material:

The steel commonly used for the main structure is Q355B; section processing technology divides it into hot-rolled section steel and welded section steel; the primary frame includes steel columns, steel beams, and crane beams. The anti-corrosion treatment on the surface of components mainly includes painting or galvanizing.

2. Secondary structure:

The commonly used steel for the structure is Q235B; it is mainly section steel, such as L-angle steel, rod steel, round pipe, and square pipe. The secondary structure includes horizontal roof and wall bracing, flange bracing, and tie beam.

The role of the secondary structure:

1) Transfer the longitudinal load reasonably and shorten the force transmission path as much as possible;

2) Ensure the stability of the structural system outside the plane, and provide lateral support points for the overall strength of the structure and components;

3) Meet the necessary strength and stiffness requirements, and have reliable connections.

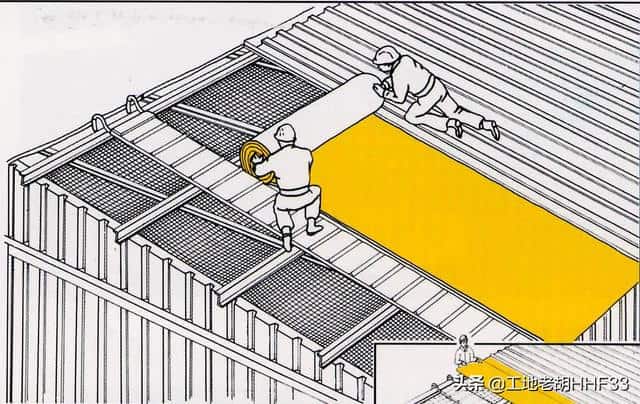

3. Roof purlins and wall girts:

The roof purlins and wall girts are made of cold-formed thin-walled steel, and their structural forms can be divided into C/Z-shaped steel. The sag rod connects C/Z steel to ensure a stable structure.

4. Fasteners

Anchor bolt: used to connect the column foot to the foundation.

Ordinary bolts: used for purlins, wall beams, and secondary structure connections.

High-strength bolts: used for the primary structure connection, including large hexagonal bolts and torsional shear bolts.

Wall and roof panel:

Roof and wall panels are mainly corrugated steel sheet and sandwich panels.

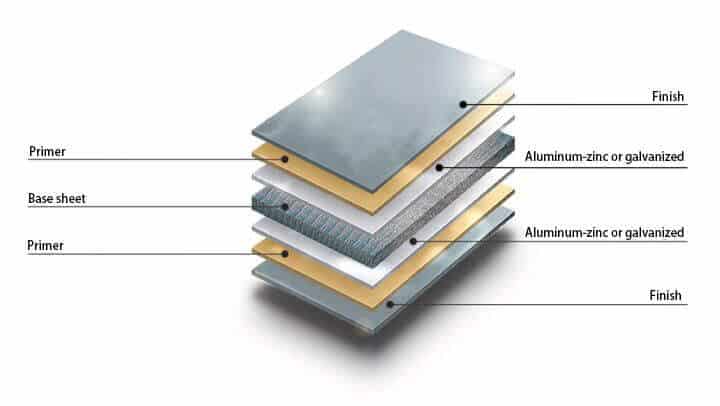

1. Corrugated color-coated steel sheet

Substrate:

Galvalume plated substrate, thickness 0.3, 0.45, 0.50mm, 0.6mm. The galvanized color-coated sheet suits buildings or other facilities in extreme environments. It is highly corrosion-resistant and weather-resistant, with a service life of over 20 years.

Coating:

Polyester coating (PE): good adhesion, wide application range, medium chemical resistance, service life of 7-10 years;

Silicon-modified polyester (SMP): good film hardness, abrasion resistance, heat resistance, and durability, limited gloss retention and flexibility, and a service life of 10-15 years;

High weather-resistant polyester (HDP): excellent UV resistance, high durability, and a service life of 10-12 years;

Polyvinylidene fluoride (PVDF): Good formability, excellent outdoor durability, and solvent resistance, but limited colors, high cost, and a service life of 20-25 years.

Glass fiber insulation wool:

The commonly used glass fiber insulation cotton has a bulk density of 12kg/m3, has good thermal insulation, sound absorption performance, and corrosion resistance. It is a non-combustible material (A1 grade) with a low moisture absorption rate.

Sandwich panel:

The sandwich panel is made of upper and lower layers of single-layer color steel sheet and a middle layer of polymer heat-insulating inner core, and the standard thickness is 50, 75, and 100mm.

Door and window system:

Doors: The commonly used forms of doors are swing doors, sliding doors, and rolling doors.

Windows: aluminum alloy sliding windows.

Ventilation system:

For steel structure buildings with large building areas and areas with high fire hazards, it is necessary to consider setting up mechanical smoke exhaust facilities or natural smoke exhaust outlets.

A roof ridge ventilator is a kind of ventilation equipment installed on the roof of a building to enhance air circulation. It is widely used in various public buildings and steel structure workshops. It has the characteristics of no power loss and easy installation.

Unpowered turbine ventilation: achieves ventilation and smoke extraction under the wind. Its lightweight, durable performance of stainless steel, for the structure with exceptional support, it can resist typhoons, is widely used in factories, and does not leak.

The scope of application of prefab steel building kits:

- Wide range of uses, applicable to various factories, warehouses, gymnasiums, hangars, etc.;

- Usually used for span 9~36m, column height 4.5~12m,

- Interlayers can be added locally.

- A crane can be installed inside.

Advantages of prefab steel building kits:

- The light roof is adopted, which is light in weight and saves steel, which can reduce the beam-column section and foundation size and reduce the cost;

- The rigid frame with a large span can change the variable section of the web height, thickness, and flange width. The web of the steel frame is allowed to be partially unstable, and the thickness of the web can be reduced by using the strength after buckling so that the properties of the steel can be fully and reasonably utilized;

- Good anti-seismic performance; there is no need to consider anti-seismic design in areas with an anti-seismic fortification intensity of 7 degrees and below.