As the primary building material for steel structure industrial buildings, light steel structures directly affect the stability of the main…

The steel structure bracing system is a minor part of the steel structure building and an essential part. In the portal steel structure, the steel structure bracing has critical functions.

It ensures the stability of the overall structure and individual components, transmits horizontal effects to the foundation and auxiliary installation works, etc. For complex layouts, the bracing system is also conducive to adjusting structural stiffness, making the stress on the structure uniform and reasonable, and improving its integrity.

Steel Structure Bracing System for Rigid Metal Frame

The bracing system can be divided into roof horizontal bracing, wall bracing, Tie rod, and Flange bracing in the rigid metal frame.

Roof Horizontal Bracing

The roof horizontal and the inter-column bracing are whole, which jointly maintains the stability of the structure and transmits the horizontal load longitudinal to the foundation through the roof horizontal and inter-column bracing.

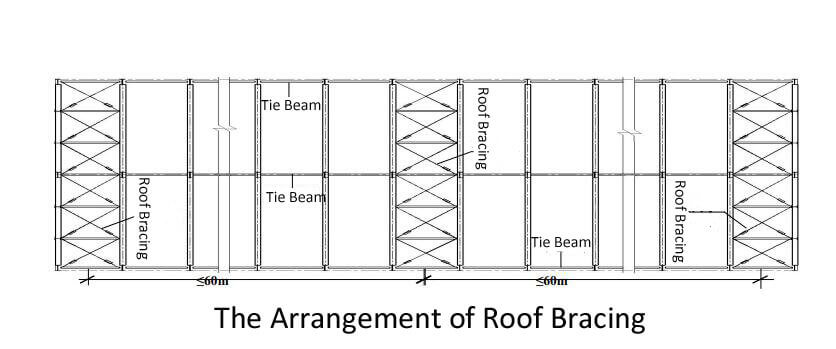

To ensure that the transmission path of the longitudinal load on the structural gable is short and fast, the roof horizontal bracing should be set in the openings at both ends of the temperature section of the building to transmit the gable load directly.

If it cannot be set up in the first bay, it can be set up in the second bay, but it must be noted that the corresponding rods that transmit horizontal loads in the first bay should be designed as pressure rods. When the building or temperature expansion section is long, one or more horizontal supports should be added, and the spacing should not exceed 60m.

Structure of roof horizontal bracing

The roof bracing is generally composed of cross rods and Pipe Struts.

The cross rods for roof bracing can be designed as round steel in a rigid metal frame. Still, a tensioning device should be added to facilitate the tensioning of the tie rods and avoid excessive deflection of the round steel, which will not be able to perform the load-bearing function.

The cross rods can also be designed as angle steel, but the deflection caused by the extended support due to its weight must also be considered, and necessary measures should be taken to overcome it. The angle between the cross pole and the vertical pole should be within the range of 30°~60°.

The pipe struts can be made of steel pipe or double-angle steel, with end plates welded at both ends and connected with the structural frame by bolts. It is arranged along the entire building length at the eave and roof ridge.

Column Cross Bracing

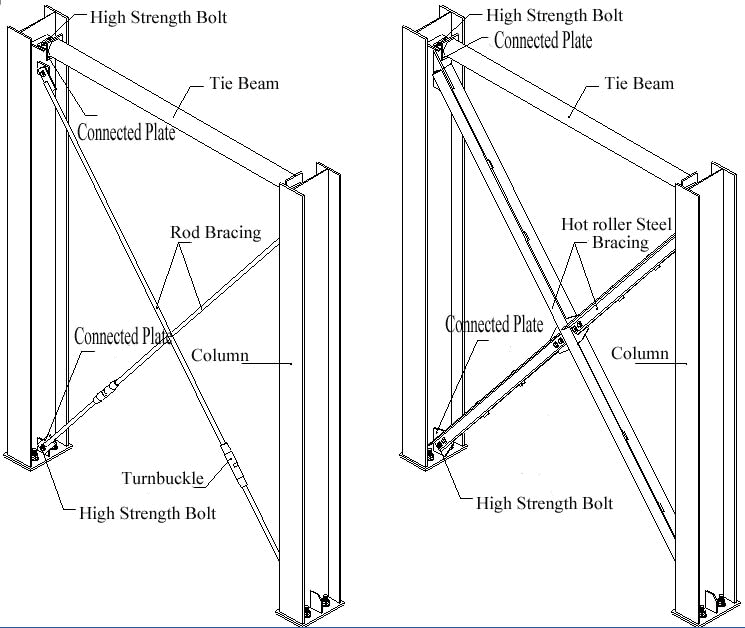

The column cross bracing, also called wall bracing, is set between two adjacent columns to ensure the overall stability of the building structure, improve the lateral rigidity, and transmit the horizontal force.

Column cross bracing is divided into two types: flexible and rigid bracing. The flexible bracing is made of round steel and must be tensioned during installation. It is mainly used for metal frame structures. The rigid bracing is made of angle steel or H beam used in structures with high rigidity requirements, such as multi-story buildings and workshops with cranes.

Why Steel Building Need Wall Bracing

Flange Bracing

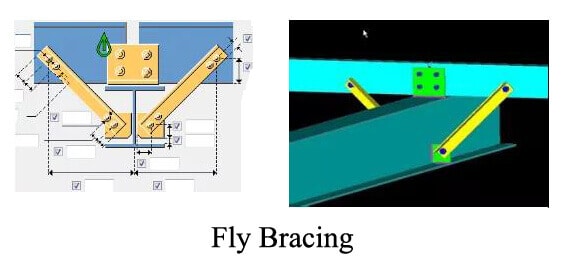

Flange bracing is made of angle steel, arranged between the roof rafter’s lower flange and the purlin or between the inner flange of the column and the wall girt. It supports the stability of beams and columns.

In a rigid metal frame, the primary structure bears the stress. The steel structure bracing system completes the force transmission and supports the beam and column. They are essential, and they are related to the safety of the installation process and the safety of the entire structure.

Steel structure bracing systems work together to form the overall stiffness of the structure. The bracing system bears and transmits the horizontal wind load of the gable wall, the seismic effect, the braking force of the crane, and the temperature stress and transmits the load to the foundation.

The principles of steel structure bracing system setting:

- Transmit the longitudinal load reasonably, and shorten the force transmission path as much as possible;

- Ensure the stability of the structure system outside the plane and provide lateral support points for the overall stability of the structure and components;

- Convenient structure installation;

- Meet the necessary strength and rigidity requirements and have a reliable connection.