A steel portal frame structure is a type of low-rise building composed of steel columns and rafters joined by rigid…

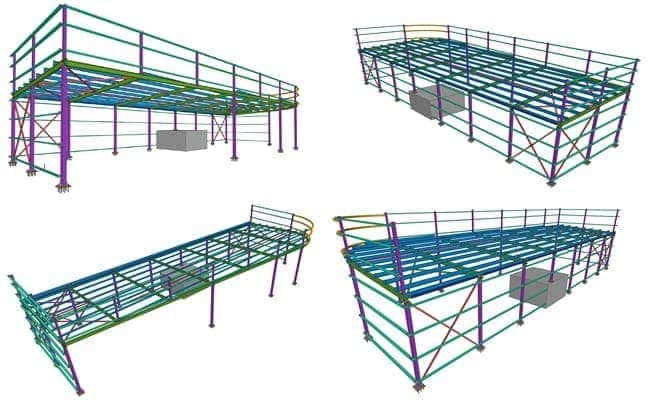

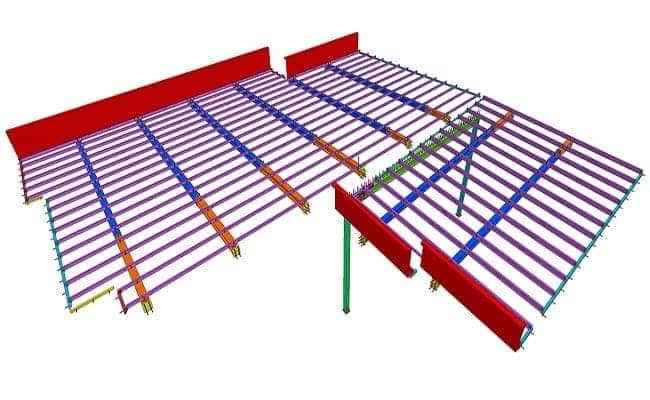

Steel structure fabrication in Israel is processed by hot-rolled section steel, including H-section steel, square tube, and C-section steel. The structural width is 9450mm, and the length is 27415mm, with a curved structure.

The steel Frame Structure, the roof rafter, and the column are used in European standards, such as HEB260, HEB300, and HEB360. The roof uses Z section purlin. All steel components are hot-dip galvanized after processing.

Steel structure fabrication in Israel

The customer provides the processing drawing for this project, and we process it according to the plan.

The steel required for this project is hot-rolled section steel, a type of steel processed through a hot-rolling process, which has high strength and durability and is often used in construction and structural engineering. H-shaped steel, square tube, and C-shaped steel are everyday hot-rolled steel products, playing different roles in different structural designs.

The processing steps of this structure are cutting, welding, and bending.

- Cutting: In the cutting process, according to the processing drawings, the required section of steel is cut according to the required size.

- Welding: Welding joins multiple steel members to form a monolithic structure. According to the processing drawings, each component is positioned, and then the connection plate, end plate, and section steel are welded using appropriate welding methods.

- Bending: Some parts need to be bent in the structure, such as arc design, and then the stretch bending process will be used. Professional stretch bending equipment is required to bend the H-beam.

Surface treatment of steel structure processing in Israel

The surface treatment of Israeli steel structure processing adopts a hot-dip galvanizing process.

Hot-dip galvanizing is an effective metal anti-corrosion method used in metal structural facilities. It is to immerse the rust-removed steel parts in the molten zinc at about 500 ℃ so that the surface of the steel parts will be attached with a zinc layer to achieve the purpose of anti-corrosion.

Hot-dip galvanizing process:

Degreasing→Washing→Pickling→Washing→Immersion in plating solvent→Drying→Hot-dip galvanizing→Cooling→Cleaning→Grinding→Completion

Advantages of hot-dip galvanizing:

- Durable: In the suburban environment, the standard hot-dip galvanized anti-rust thickness can last more than 50 years without repair; in urban areas or offshore areas, the standard galvanized anti-rust layer can be maintained for 20 years.

- Good reliability: The combination of the galvanized layer and the steel is a metallurgical bond, which makes zinc a part of the steel surface. Hence, the durability of the coating is better.

- Strong toughness: The galvanized layer forms a unique metallurgical structure that can withstand mechanical damage during transportation and use.

- Comprehensive protection: All plated parts can be coated with zinc; even the recesses, sharp corners, and hidden places can be fully protected.

- Save time and effort: The galvanizing process is faster than other coating construction methods, and it can avoid the time required for painting on the construction site after installation.

- Reliability: BS EN ISO 1461 generally implements hot-dip galvanizing specifications, which limits the minimum thickness of the zinc layer. Hence, the anti-rust period and performance are reliable and predictable.

Precautions for steel structure fabrication:

Quality of raw materials

It is divided into several kinds of processing and manufacturing. The first is raw materials. The purchase of raw materials must go to regular manufacturers or agents, and there must be certificates and raw materials. Before production and processing, a sample must be taken for retesting and can only be used after passing the test.

The quality of the welding rod

Steel structural parts are fabricated mainly by welding operations, so the welding rods should also be selected from qualified regular manufacturers, and there must be material statements. Electrodes should be dried in a drying oven before use. The wire and flux set for submerged arc welding must match the base metal used.

Welder certificate

Steel structure welding is a particular operation. Operators must undergo technical and safety training and obtain relevant certificates before they can work with credentials. Otherwise, they cannot perform welding.

Welding process

The welding sequence of the steel structure should formulate a reasonable welding process. When welding several kinds of welds, the welds with more considerable shrinkage deformation should be welded first. Then the longitudinal welds should be soldered, which is the skill of steel structural members in the welding process. The production and processing of steel structures pay attention to precision, and strict requirements on accuracy and operation are required from blanking to welding.