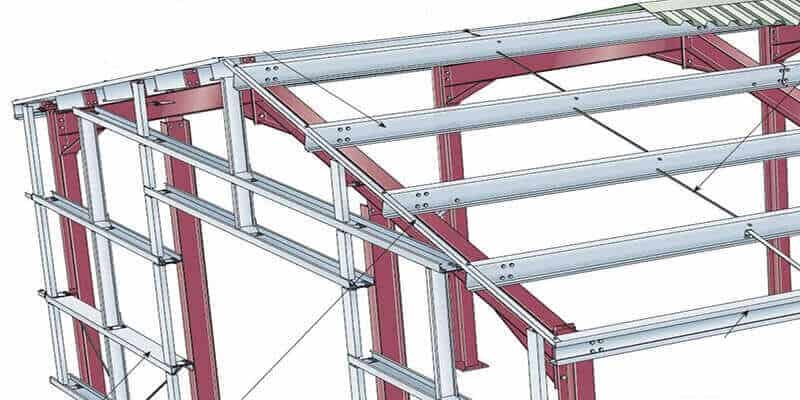

A steel frame is a structure made of steel, usually connected by welding, bolting, or riveting steel beams, columns, bracing,…

Steel structure building has developed in our country for decades, and the roof leaking on metal buildings is a very difficult problem at present. Roof leaking on Metal Buildings due to installation, material deformation, roof vibration, and other reasons. Therefore, Roof leaking on Metal Buildings has become the top priority. Waterproof engineering includes the design of waterproof points, materials, strict construction management, and regular maintenance. Otherwise, it will be commonplace for the workshop to make up and leak.

Roof leaking on Metal Buildings

A large amount of past data shows that more than 90% of the leaks are due to negligence on the following leaks, so the key is to understand the reasons for these leaks and take adequate measures.

Roof leaking on Metal Buildings: Roof ridge

Reasons for water leakage: the roof ridge crest is too high, and the overlap of the roof ridge cover will form a gap and leak water. At the same time, the ridge cover connects with rivets, and the rivets will loosen over time and create water leakage points. Finally, there is no plug between the roof ridge cover and the roof panel, or the closure position is improperly placed and falls off, and water will leak.

Solution: widen the roof ridge cover, and find a more significant slope; put glue or silica gel on the overlap; replace the suture nails; the closure should match the slab board, and put glue or silica gel up and down when laying the closure.

Roof ventilator

Reasons for water leakage: no foam closure placed under the edges of the air-floor and roof junction, and no glue or silica gel is applied to the longitudinal lap of the edges; the outer roof panel is not installed at the air-floor intersection; the openings of the pillars of the air-floor structure are not open. Waterproof treatment; the production and installation of the gas building itself may cause water leakage.

Solution: Foam closure should be laid before the edge closing installation, and the longitudinal overlaps should be set with cement or plugs and fixed with suture nails; the roof panels must be pulled up before the ventilator installation; the ventilator construction party must be required after the ventilation structure is completed Waterproof the openings; check the installation quality and waterproofness of the roof ventilator.

Gutter Leaking

Reasons for water leakage: There are gaps in the welded joints of the inner gutter, resulting in water seepage; the design of the gutter and rainwater pipe diameter is too small, which does not match the slope length of the plant; the end of the gutter is not made of the head plate; the length of the outer roof panel extending into the gutter is insufficient, The water will flow back into the plant.

Solution: Properly increase the depth of the gutter so that the rainwater in the gutter does not exceed the lap joint.

Daylighting sheet:

Reasons for water leakage: the type of daylighting board does not match the roofing board. The wave peaks on both sides of the daylighting board are higher than that of the roofing board. After installation, the air pressure difference between the inside and outside of the daylighting board is formed, and capillary water leaks into the roof from the gaps on both sides of the daylighting board. ; The longitudinal lap length of the daylighting board is not enough. The cement aging loses its viscosity; the longitudinal mortar falls off; the daylighting board and the color steel plate are rigidly overlapped, and the gap in the middle is not sealed.

Solution: The waterproof screw is applied to the upper part of the wave crest; the edge receiving board at the daylighting board should be tightly sealed with the daylighting board, the glue on both sides of the longitudinal direction should be widened, and the upper part of the wave crest should be laid to prevent capillary water from infiltrating.

Cornice leaking:

Reasons for water leakage: no foam plugs are installed on the outer roof panels, the length of the exterior wall panels is not enough, and the cornices are not waterproofed. The above parts are essential leak points.

Solution: When installing the outer roof panel, a foam closure should be placed simultaneously, and the outer roof panel should be lowered by 30 degrees; the cornice should be added with a closed edge according to the design requirements.

Attention for Roof Leaking on Metal Buildings

The roof leaking on metal buildings has a lot of factors that need attention. First, this is not an ordinary cement waterproof roof. Specifically, we need to pay attention to the following aspects.

A. Building structure problems:

1. The design of the purlins on the roof is not satisfactory, resulting in a large deflection of the roof and cracks in the roof panel. The roof winding is too large, or the slope is too gentle, resulting in water accumulation. The downward deflection of the roof beam causes the part of the glue that is stretched and overlapped by the roof panel to fall off.

2. The gutter section is not enough. The cross-section design of the inner gutter is too small, and the collection of local hydrogeological data is ignored in the design of many light steel structures. The local heavy rainfall is underestimated, resulting in poor drainage of the inner gutter and internal irrigation. In addition, the node design of many outer gutters does not conform to foreign standard practices, resulting in water creeping. It is also a reason for the self-priming roof ventilator used in the workshop with a large amount of dust to stop, which is also a hidden danger of rain leakage.

3. The diameter of the downspouts is too small.

4. If the above designs are satisfied, it may also be caused by water choking during heavy rain because there is no downspout.

B. Waterproof material problem

- The waterproof grade of the metal buildings is designed at a lower level, such as below grade III waterproofing. After a certain number of years, there will be problems with the roof leaking on metal buildings, and at the same time, the maintenance will not cause the roof to leak in time.

- The thermal conductivity of the roof metal sheet itself is large. When the external temperature changes significantly, due to the large change in the ambient temperature difference, the color steel sheet shrinks and deforms due to the temperature change, and a large displacement occurs at the interface, so it is very easy to occur at the interface of the roof metal sheet—water leakage hazard.

- In the steel structure buildings, because the structure itself is prone to elastic deformation under the action of external force such as temperature change, wind load, snow load, etc., the displacement of the connection part will cause the hidden danger of water leakage;

- For particular parts, due to the use of different materials for connection, such as the connection between the parapet and the eaves gutter made of steel plate, the roof lighting belt, and other parts, due to the asynchronous change of stress, there is a hidden danger of water leakage.

- Due to the cost factor, most of the roof panels used in some light steel buildings are panels with low wave crests, and the width of the overlap is small.

- Due to the minor consideration of roof deformation in the design, the deformation of the waterproof layer is smaller than the deformation caused by the temperature stress of the roof, and the cracking or edge opening may also cause water leakage.

- Improper selection of panels, suitable roof panels should be selected for different spans and slopes (also considering local rainfall conditions). For example, for some projects with large single-slope spans and relatively small slopes, medium-wave or high-wave color panels should be given priority, and the connection method should be in the form of a hidden buckle or bite.

- Roofs fixed with self-tapping screws are also prone to water leakage. Use dark gussets as much as possible.

C. Human factors:

- The damage to the waterproof layer of the roof caused by human factors in the use of non-superior roofs may lead to roof leakage.

- The sewers are not smooth, and the gutter is filled with leaves, causing reverse water.

- The roof panel was trampled during construction, causing water accumulation.

- Due to quality reasons, the exposed self-tapping screws on the roof will break when there is vibration, leaving holes on the roof panel and leaking water.

- Roof leakage is sometimes caused by water absorption of thermal insulation materials. Some projects use double-layer color steel sheet thermal insulation cotton, but the thermal insulation cotton does not add aluminum foil. This vapor barrier layer is missing. After a long time, a large amount of water vapor condenses on the roof, resulting in water droplets in the room. At this time, it affects the thermal insulation effect and increases the dead load of the roof after the thermal insulation cotton absorbs water. It will be hazardous to encounter a significant snow load!

The waterproof design must be reasonable to prevent roof leaking on metal buildings and pay more attention to and check the above problems. According to the function and use of the steel buildings, the waterproof level and proper roof insulation structure can not only bring a comfortable temperature environment. It can also prevent leakage, protect the quality of the building, and increase the life of the building.

When making waterproof designs, carry out detailed planning for the mentioned parts likely to cause water leakage, multiple fortifications, and node seals. It is also essential to choose high-quality waterproof materials. A significant reason for engineering water leakage is the aging of waterproof materials. Therefore, we must select high-quality, high-end waterproof materials first.

In addition, it is necessary to regularly check whether there are any hidden dangers of water leakage. Once any signs of water leakage are found, must repair them in time. Otherwise, waiting for the water leakage opening to be large will delay the use of the plant and cause more significant economic losses.