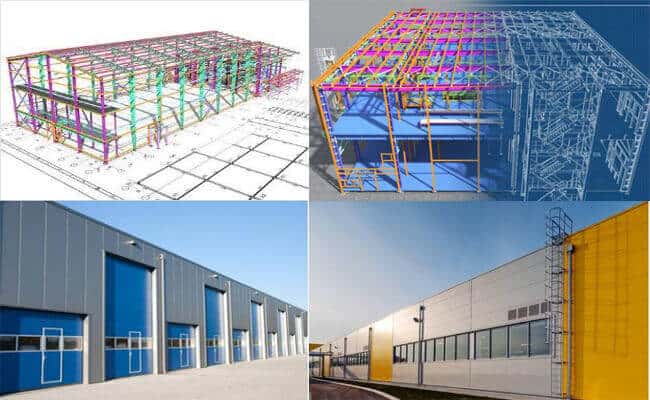

In the construction of modern storage facilities, steel structure warehouses have become one of the mainstream building forms due to…

The industrial steel garage building can improve the practicality and functionality of the plant, reduce the comprehensive cost, and increase the structures’ service life. During the design process of steel structure, it is necessary to analyze several influencing factors to meet various requirements in the construction process and ensure the industrial garage building’s safety while meeting the economy’s requirements.

Overview of Steel Structure

Generally speaking, the steel structure is divided into two major structures: heavy steel structure and light steel structure. Heavy steel is mainly used in heavy industrial projects, which need to bear a lot of loads. Light steel is used in the portal frame, with some light wall structures. Compared with heavy steel, the weight it can bear is much smaller.

Industrial Steel Garage Building VS Concrete Structure

Compared with concrete structure design, steel structure industrial garage buildings can reduce the design difficulty and improve industrial garage buildings’ construction efficiency.

More construction materials can be saved during the structural assembly process, and the construction economy is better. It is an important factor for the large-scale application of steel structures at present.

In the industrial steel garage building, a large space can be designed to meet different industrial requirements and ensure the reasonable application of the upper space, thereby effectively controlling the process equipment and saving more project construction costs. The steel structure is a building material with a high utilization rate and can be used many times. Its installation and operation require less workforce and material resources.

Advantages of Industrial Steel Garage Building

Large span

The key advantage of a steel industrial garage building is the ability to form a larger Span. The actual performance is as follows: First, compared with other materials, the steel structure has stronger flexibility and is very light.

Second, the convenient installation and disassembly structure save operation time. In actual installation operations, most of the work is done mechanically, reducing labor costs.

Lightweight

During construction operations, the weight is relatively light, which minimizes the bearing capacity of the foundation. Simultaneously, the structural system has gradually improved the seismic capacity and simplified the operation process. The cold-formed thin-walled structure improves the anti-corrosion level to a certain extent and increases the project’s application time.

Anti-Seismic

The steel structure has high plasticity and toughness. Therefore, they can effectively prevent earthquake disasters while minimizing damage.

Industrial Steel Garage Building Design

Fireproof design

Industrial steel garage building is more susceptible to temperature changes than concrete structures, and their fire resistance is not strong. Therefore, it is necessary to strengthen the fire and heat insulation design of steel structures. Fire-resistant paint can be painted on the surface of the steel structure.

Anti-corrosion design

When the environmental humidity is high, the oxidation reaction will be accelerated, resulting in more obvious steel structure corrosion. It is necessary to apply anti-corrosion coatings to the steel structure to ensure that the external environment’s corrosive factors will not directly contact the structure, effectively protecting the structure.

Seismic design

In the structural design of a steel garage building, seismic design is essential. In the design process, the steel structure should be reasonably arranged to improve the structure’s force transmission performance, thereby improving the seismic performance of the structure.