In the construction of modern storage facilities, steel structure warehouses have become one of the mainstream building forms due to…

From the first iron bridges of the Industrial Revolution to the soaring skyscrapers of today, steel has transformed how we build. Its strength, versatility, and durability have allowed architects and engineers to dream bigger, reach higher, and shape the skyline of cities worldwide. Join us on a journey through the fascinating history of steel structure buildings—where innovation meets artistry, and steel forged the foundation of the modern world.

Any actual design should be premised on transcending the status quo. To create innovative architecture, we need a deep understanding of what has happened in the past and insights into the changes that may occur in the future. In this process, integrating the history of steel structure buildings into our designs has become essential to finding inspiration.

History of Steel Structure Buildings:

1. From the end of the 18th century to the beginning of the 20th century

The history of steel structure buildings can be traced back to England at the end of the 18th century. Because fires often occurred in cotton mills at that time, and brick walls hindered the machinery layout, iron frames were used in the factory structure.

Joseph Needham once recorded: “The installation of huge cast iron roof trusses in some buildings in France was just before the revolution, and the truly epoch-making building was the one built by Charles Bage (1752-1822) in France in 1797. A five-story flax factory was completed in Shrewsbury, which is still well preserved today. The cast iron beams are supported by cast iron columns and connected with brick semi-circular arches, thus forming the first iron frame “Building.” It is a building with a masonry-iron frame hybrid structure.

After the successful attempt at masonry-iron frame hybrid structure buildings, some long-span single-story buildings that needed to be constructed quickly, such as markets, railway station sheds, greenhouses, exhibition halls, etc., adopted iron structures. By the middle of the 19th century, the famous “Crystal Palace” appeared in Europe, and multi-story commercial buildings with all-iron frames appeared in the United States.

London’s Crystal Palace was built for the 1851 World’s Fair and was the brainchild of gardener Joseph Paxton. Based on his experience using iron structures to build greenhouses, he successfully solved many problems such as function, construction speed, economy, aesthetics, etc., showing the strong vitality of new materials and structures. It was hailed as the first example of contemporary architecture in the 20th century.

Although the Crystal Palace in London has epoch-making significance, it is a low-rise iron frame structure, and the technology is not yet mature. It was not until 1885 that the world’s earliest iron-frame high-rise building, the 10-story Home Insurance Building designed by Jenney, was born in Chicago.

At the same time, steel production in various countries has increased rapidly, and prices have dropped. Steel’s high strength, good toughness, and plasticity dwarf those of iron. As a result, iron structures were gradually replaced by steel structures. With computing theory advances, steel production significantly enhanced buildings’ height and span.

The History of Steel Buildings: The Development of Ultra-Tall Steel Buildings

The first leap forward in height was the Eiffel Tower, built in 1889 to commemorate the 100th anniversary of the French Revolution. The tower is 300 meters high and has 12,000 components, connected with 2.5 million bolts and rivets, using 7,000 tons of high-quality steel. The Eiffel Tower has stood for over a hundred years and has become a symbol of Paris. But it is not only a symbol of Paris but also a symbol of human wisdom and strength and a symbol of promoting the spirit of democracy. At the same time, it also heralds mankind’s arrival at the age of steel.

In 1891, a 22-story steel structure appeared in Chicago. In 1898, a 26-story steel structure was built in New York. In 1913, the 241m-high Walworth Building in New York was built. Thus, the actual era of skyscrapers began.

While the height is leaping forward, the span of the building is also constantly jumping ahead. In 1849, a station in Liverpool adopted iron trusses with a span of 46.3 meters, which for the first time exceeded the span of the Pantheon in Rome (43.3 meters). In 1868, a station shed in London used iron arch trusses spanning 74 meters. In 1893, the span of a train station shed in Philadelphia, USA, reached 91.4 meters. One is bigger than the other. Many of these station sheds have been preserved today, and some are still used as railway stations.

The history of steel structure buildings: long-span steel buildings

Before entering the 20th century, the most prominent building built by mankind was the Machinery Exhibition Hall of the 1889 Paris Exposition. It used the most advanced three-hinge arch structure and high-quality steel at the time to make the span of the building reach 115 meters, which can be called a great leap forward in span!

The exhibition hall has 20 such steel arches, forming a vast indoor space with a width of 115 meters and a length of 420 meters, with no obstruction inside. This building was probably the most exciting at the time and might not have been demolished in 1910 had it not been overshadowed by the Eiffel Tower.

The rise of reinforced concrete buildings:

Although steel structures made significant progress in building height and span in the late 19th century, their penetration into construction fields that do not have special requirements for spans and loads has not been smooth. One reason is that conservative attitudes and a tendency to cling to routine and custom are extreme in these areas, especially in residential construction. Another main reason is the rise of reinforced concrete structures.

In the 1890s, reinforced concrete began to be used in house structures. The German builder F. Hennebigue (1842-1921) was the first to use reinforced concrete to build complete houses. He used reinforced concrete structures to build bridges, factories, barns, water conservancy projects, and department stores in many European places. France was in the leading position in reinforced concrete structures at the time.

The Saut-Jean de Montmartre church, built in 1894, was considered the first reinforced concrete structure made with artistic value. By the beginning of the twentieth century, reinforced concrete structures had been widely used. It was adopted, hindering the progress of steel structures in the next half-century.

When the First World War ended, concrete construction caught up and maintained its advantage for half a century, primarily due to technical reasons. Even as early as the twenties, steel structural engineers must have sensed the need to perfect their technical and scientific methods to succeed, at least in constructing high-rise and long-span buildings over reinforced concrete. At that time, steel framing for multi-story buildings was about where it had been in the United States in 1900. In particular, the structural analysis of steel frame buildings is even more immature. Each floor beam, joist, and column are considered independent components and are only assumed to be supported at the nodes.

Around 1930, steel structure designers had difficulty copying and applying reinforced concrete calculation models and structural techniques (gusset plates, connecting angles, and riveting). The tower of Torrengebo was built in Antwerp in 1931. A typical structural node of Torengebouw is an obvious example. Compare this node to a functionally similar node in a steel-framed building built in Zurich in the 1950s, and even a layman can see how much effort went into perfecting a three-dimensional design problem; the transition from riveting to welding and high-strength friction bolt connections has improved the method of structural connection. What a vast progress this means!

2. Early 20th century to mid-20th century:

When building construction resumed after World War I, steel structures had taken a backseat, both in quantity and in the minds of architects and their clients. However, the competition between steel and reinforced concrete has intensified ever since. Looking at the overall effect or carefully considering the progress of the building structure, nothing can be gained from the competition between the two materials. This will go a long way in promoting the development of construction technology and engineering science.

In the 1920s and 1930s, steel frames for multistory buildings were roughly where they had been in the United States in 1900. In particular, the structural analysis of steel frame buildings is even less mature. Although steel structures are constantly making progress in competition with reinforced concrete structures, they are still at a clear disadvantage.

This state lasted half a century and did not turn around until the 1950s. During this period, steel was mainly used to build factories, hangars, etc., which were monotonous. Of course, in the low ebb of the development of steel structures, buildings are not without bright spots, and many bright spots shine in the works of masters.

Corbusier, Mies, and Wright’s exploration of steel structure buildings

Le Corbusier

Le Corbusier, a legendary figure, has always been the master of concrete in people’s minds. He also devoted himself to studying steel structures and made essential contributions to developing steel structure buildings. Unfortunately, this is little known.

In the Swiss student dormitories designed for the Paris University City from 1930 to 1932, he combined the advantages of reinforced concrete and steel structures to complete the design, thus creating an architectural form. The deeply recessed building has six pairs of widely spaced reinforced concrete columns on the ground floor, supporting the upper four-story steel structural frame. The slender members of the frame clearly show its outline in the facade: small columns and small columns between the windows. The spacing of the crosspieces has a vague rhythm, which is the predecessor of the curtain wall.

During the same period, Le Corbusier also used steel structures to design the Light Building in Geneva, the double-story steel house in the Weissenhof residential area in Stuttgart, and the Dr. Dalsace residence in Paris. He was also often at the forefront of applying new structures. In 1937, at the Paris World’s Fair, the “New Era Pavilion” (Le Pavillon des Temps Nouveaux, 30 meters × 35 meters) used a suspension structure. In 1939, he proposed a more novel hanging curtain exhibition hall. It can be said that Le Corbusier was also a pioneer in steel structure buildings.

Mies van der Rohe

Mies van der Rohe was a master of steel and glass. His main contribution lies in his long-term focus on exploring the possibilities of applying two modern materials, steel and glass, in architectural design, mainly focusing on these materials’ characteristics and expressive power in architectural art modeling.

From the German Pavilion in Barcelona in 1929 to the West Berlin Kunsthalle in 1968, from the single-story Farnsworth House to the 38-story Seagram Building, he has continued his exploration in this area. Mies’s steel structure works were mainly concentrated in the 1950s and 1960s, and their influence was particularly huge, as evidenced by the large number of “Miesian Architecture” emerging. Although not many of Mies’s early works used steel structures, and their techniques were not as sophisticated as those of his later works, they still shone with dazzling light.

1929, Mies designed the famous German Pavilion (Barcelona Pavilion) at the Barcelona World Expo. The exhibition hall is located on a low base. The main hall adopts a steel structure. Eight chrome-plated steel columns with a cross-section support a thin roof panel about 25 meters long and 14 meters wide.

The partition walls are made of glass and marble. The details are straightforward, and the position is very flexible, thus creating a meaningful and changeable circulation space that fully embodies the architectural principle of “less is more.” Although its existence was short-lived, it greatly impacted modern architecture.

The Tugendhat House, built in 1930, was one of Mies’s early works exploring the art of steel and glass. This house’s design concept and structural form were precisely the same as the German Pavilion at the Barcelona World Expo and achieved great success. The Tugendhat House is one of Europe’s most famous modern residences after Le Corbusier’s Villa Savoy (1928-1930).

After Mies came to the United States in 1937, he concentrated on exploring the architectural design issues of steel structures. Once World War II was over, it bore fruit. Designed in 1945 and completed in 1950, the Farnsworth House was comparable to the German Pavilion in Barcelona in 1929, and there has been considerable progress in the use of steel and glass. The structural details of this house have been carefully considered, and it looks very sophisticated. Rather than a house, it is more of an architectural souvenir, a statement of steel and glass.

Wright

Wright, a disciple of Sullivan, participated in the design of the Wainwright Building (1890-1891). The Wainwright Building was the first fully-fledged steel-frame high-rise building designed by Adler Sullivan and others. From this practice, Wright’s understanding of steel and steel structures deepened.

After Wright opened his own business, he repeatedly used steel in structural girders and cantilevered girders in residential buildings and made many attempts to use steel structures in public buildings.

For example, in 1926, Wright made a design sketch for an all-steel structure church. The building is shaped like a polygonal pyramid, with steel beams rising directly from the foundation and intersecting diagonally at the ends. The beams are lightly decorated with geometric shapes, so the upper steel structure forms an elegant pattern while reflecting the underlying structural purpose. However, due to the technical conditions at the time, this cathedral’s plan to accommodate 100,000 people was impossible to realize. Although the plan could not be realized, this did not hinder Wright’s interest in steel.

He researched steel’s physical and chemical properties and processing technology in depth. In 1927, he said, “This is the age of steel, and our culture has accepted it just as ancient Rome accepted the great gift of masonry.

He criticized many architects at that time who did not understand the correct use of steel but followed the old ways and were keen to cover the appearance of classical masonry buildings outside of steel structures. In response, Wright proposed that steel structures should be expressed scientifically and artistically. 1938, he designed the Anne Pfeiffer Chapel for South Florida State University. The interlaced geometric lattice of steel frames on the top fully demonstrates the beauty of steel structures.

From today’s perspective, Wright’s analysis of the properties of steel is not profound. However, his efforts to understand the material and his conscious efforts to express its characteristics in architecture are valuable revelations left to us by Wright.

American skyscrapers

After the Chicago School disappeared in the United States at the end of the 19th century, the style of antique architecture spread throughout the United States. Even skyscrapers, utterly different from all previous architectural forms in function, structure, volume, form, etc., were not immune.

The American skyscrapers built in the first 30 years of the 20th century tried their best to apply various architectural styles from European history to their bodies, either entirely or piecemeal. In 1913, Walworth Company, a prominent American retailer, built a 57-story building in New York with a height of 234 meters. Its shape imitated the details of a European medieval Gothic church. Woolworth Building (Woolworth Building, New York, 1911 ~ 1913, architect Cass Gilbert) became the tallest building in the world at that time.

Another skyscraper considered “unrivaled in traditionalism” is the 1918 Chicago Tribune Tower. From 1922 to 1927, this antique newspaper building had an octagonal tower built on the top of the 24th floor, with antique flying buttresses and various carvings, a typical Gothic style.

American skyscrapers changed their architectural concepts after the 1930s and continued until World War II. Historically, detailed designs and decorations at the top of the facade or in the transition area became less and less and were eventually abandoned.

Concave-convex surfaces are a system of vertical or horizontal bands that replace traditional elements of the exterior architectural treatment. The structural system, namely the steel frame, is left exposed, emphasizing the feeling of strength. The transformation of American architectural culture was evident in the construction of several new skyscrapers in the 1930s.

An earlier example is the Philadelphia Saving Fund Society Building, architected by George Howe and William Lescaze. The entire appearance of the building is consistent with the internal space, is asymmetrical, and has no additional sculptured decorations. It gives people the impression of being practical, simple, straight, and fresh, altogether abandoning the old composition rules of academic architecture. The Philadelphia Financial Institution’s steel structure building was the first high-rise building built in the modern style in the United States and the world.

A group of steel buildings that can not only represent the creativity of that period but also surpass that period and acquire a tremendous timeless quality is New York’s Rockefeller Center (Rockefeller Center), which R. Designed by a small group, construction started in 1931 and continued until World War II. Rockefeller Center has 15 buildings, the tallest of which is the 70-story RCA Radio Building.

The 38-story International Tower and the 36-story Times and Life Tower follow it. All buildings in Rockefeller Center repeat the basic style and standard dimensions of the Radio Building, making the whole appear harmonious and unified. Here, the vertical treatment has no monumental sentiment and only reveals a hint of romanticism, presenting a joyful yet solemn scene. For the first time, it unifies buildings with complex functions, modern steel structure engineering, and spectacular appearance in large urban building complexes.

During this period, there was another work worthy of special mention – New York’s Empire State Building (“Empire State Building,” 380 meters), designed by Shreve Lamb Harmon—architectural office. The Empire State Building was the tallest in the world before World War II, surpassing the height of the Eiffel Tower in Paris for the first time. Its shape is straightforward, with no unnecessary decoration. Only the round tower with a diameter of 10 meters and a height of 61 meters at the top of the building is slightly decorative.

Industrial building

At the beginning of the twentieth century, industrial architecture led to a new trend in world architecture. Many industrial buildings occupy an essential position in the history of modern architecture, such as the turbine workshop designed by Behrens and the Fagus Factory designed by Gropius.

The turbine workshop has an almost timeless monumental quality with its remarkable details, the portal solid steel frame pillars, the so-called roof structure sculpture, and the gable end’s intricate symmetry.

The Fagus Factory, ranked among the most advanced architectural creations of those years, was a forerunner of modern architecture. However, its load-bearing structure was not as exposed as the turbine shop. Compared with buildings of the same period, the all-glass facade of the three-story factory building and its protruding transparent corners were once seen as a sensational and bold design. This facade is one of the earliest and most important of the many predecessors of the glass curtain wall.

After their initial glory, industrial buildings gradually transitioned into mediocrity. A well-known industrial building in the 1920s was the Siemens-Schuckert Switchgear, designed by Hans Hertlein from 1926 to 1928. The steel frame spanned several. It is a continuous production area without intermediate support. The facade treatment emphasizes the vertical composition, giving it an elegant, pleasant, solemn, and simple feeling.

The period of mediocrity began in the 1930s and lasted until the late 1950s. It was not until the 1960s that new trends emerged, and improvements were made in many aspects.

Mid-20th century to late 20th century

The Second World War brought all kinds of civil construction activities near a standstill. After the war, many houses needed to be built and rebuilt, resulting in a shortage of building materials (especially a shortage of steel). The steel supply shortage directly restricted the development of steel structures and buildings.

At this time, the development of reinforced concrete structures was unprecedented. This situation did not change until the 1950s when steel structure buildings began to recover, but progress was still plodding.

After the 1960s, the supply of steel was fully guaranteed, and construction steel also made breakthroughs, such as the advent of new colored profiled steel plates, new high-efficiency cold-formed thin-walled steel, and the third generation of hot-rolled steel—H-shaped steel. While breakthroughs were made in construction steel, the progress in computing theory and processing methods was also epoch-making. Of course, the most revolutionary innovation is the application of computers.

With the help of computers, the development of light steel structures, space steel structures, high-rise steel structures, steel-concrete composite structures, etc., has entered an actual golden age.

Light steel building

During a period when the development of steel structures was generally suppressed, light steel buildings developed. During World War II, light steel structures constructed aircraft hangars. When the industry began to grow again after the war, attention was focused on the strength and low cost of this rapidly constructed building rather than on changing its appearance.

After the 1960s, simple and unattractive light steel buildings gradually entered the architectural palace with surprising and beautiful colors and curves. Subsequently, they became widely popular in the low-rise and multi-story non-residential building markets. Light steel buildings have now monopolized the low-rise, non-residential building market. The latest data shows that light steel buildings have accounted for more than 70% of the market for non-residential buildings below two stories in the United States.

Light steel buildings can be seen everywhere in developed countries. Here are a few outstanding examples.

(1) Dunkirk College Student Restaurant, France

(2) Jules Verne High School in the suburbs of Paris, France

(3) American light steel housing

Space steel structure building

Suspension structure building

Before the 1950s, Mendelssohn, Le Corbusier, and others had conceived architectural plans for suspension structures. By the 1950s, many engineers were already working hard to explore how to use suspension structures in buildings rationally and to solve the technical and economic problems of suspension structures.

In 1952, the Raleigh Arena in North Carolina, USA, created the history of modern suspension structures.

The Departure Hall of Washington’s Dulles International Airport (1958-1961) and the Yale University Ice Hockey Arena (1956-1958) designed by Iero Saarinen are very successful classics. Subsection 3.1.1 introduces these two works in detail.

The Burgo Paper Mill (Mantua, 1961-1962), designed by Nervi, is also a masterpiece of suspension structure architecture. Between four huge inverted Y-shaped reinforced concrete portals with a height of 50 meters, Four flat steel catenary chains with a clear span of 163 meters are suspended to lift the entire steel truss roof, with both ends protruding 43 meters each. This structure adapts to the requirements of the production process and is novel and unique in shape.

The swimming pool and basketball stadium for the Tokyo Olympics (1964), designed by Japan’s Kenzo Tange, successfully used suspension structures to create buildings with national characteristics, raising the artistic expression of suspension structures to a new level.

After the 1970s, suspension structures became increasingly mature. A large number of suspension structure houses were built around the world, such as the Leningrad Stadium in the Soviet Union (1976, 160 meters in diameter), the Milan Stadium in Italy (1976, 140 meters in diameter), Saudi Arabia’s Riyadh Olympic City Racing Stadium (1977, 166.5 meters in diameter), etc.

In 1999, the 108,000-square-meter David L. Lawrence Convention Center built in Pittsburgh, USA, was influenced by the city’s many suspension bridges and prioritized the suspension structure system.

Grid structure and grid shell structure building

Grid and lattice shell structures emerged on the structural stage after the 1960s and soon replaced the reinforced concrete shell structure, becoming the main contemporary large-span space structure form.

Grid structure building

In 1964, I.M. Pei used large-area flat-panel grids in the Kennedy Library to broaden visitors’ horizons and build a monument.

In 1970, Tange Kenzo designed a vast steel roof covering the “Festival Plaza” at the exposition’s entrance. He hoped to use it to express his architectural philosophy: “Building space for human communication,” making the square “a place of noble communication for mankind.” Place.” He indeed got his wish, and the vast space of 330 × 120 meters covered by the grid became a “communication center.”

In 1980, Philip Johnson’s “Crystal Church ” boldly abandoned the traditional church form and wholly used space steel grids and glass to form the roof and walls. Architects rely on grid technology to create an exciting and robust religious atmosphere.

Reticulated shell structure building

Industrializing building components has injected strong vitality into developing reticulated shell structures. In the past 40 years, countless grid-shell structures of various forms have been built worldwide. The span is getting broader, the shape is getting more and more novel, and it can be moved and closed, truly realizing a “breathable” building.

In 1958, Fuller designed an automobile repair shop in Baden Rouge, Louisiana, USA. It was entirely covered by a geodesic dome with a diameter of 117 meters, the longest-span building in the world at the time.

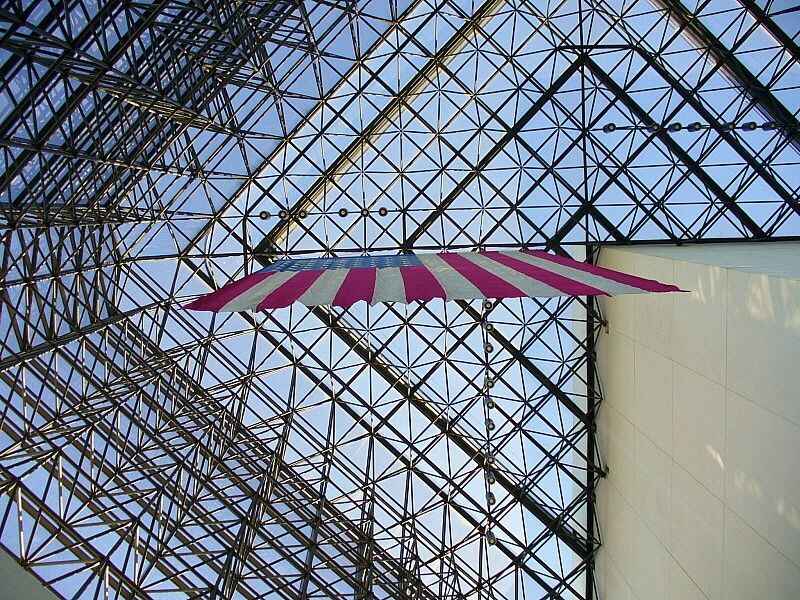

In 1967, at the Montreal International Exposition held in Canada, the U.S. Pavilion designed by Fuller once again set a precedent for substantial spatial structures. Its giant 3/4 spherical lattice shell had a diameter of 76 meters. The design of the U.S. Pavilion properly handled the different architectural and structural requirements and achieved great success.

In recent years, reticulated shell structures have been increasingly used in large-span buildings such as sports and transportation buildings. The Graben Arena in Stockholm, Sweden, built from 1987 to 1989, is currently the largest spherical building in the world.

London’s Third International Airport, Stanstead Airport, completed in 1991, and Hong Kong’s Chek Lap Kok International Airport, completed in 1998, were combined by Foster Architects using grid shell structures and units (each unit is 36m × 36m ) to obtain examples of large spaces. This method of breaking it into parts reduces the cost (the cost of the Stansted Airport is 20% lower than similar buildings) and makes the entire roof appear light, transparent, and exquisite.

Space lattice shell structure building

The Pittsburgh Synagogue in the United States, built in 1961, has a diameter of 127 meters and a height of 33 meters. Its hemispherical roof can be opened and closed freely. The roof comprises eight mesh panels, of which two are fixed, and six are rotatable. Since then, many open- and closed-space structures have been constructed.

In 1989, Toronto, Canada, built the Skydome, the world’s longest-span opening and closing structure at that time, with a span of 205 meters and a coverage area of 32,374 square meters. Four years later (1993), this record was broken by the Japanese Skydome with a span of 222 meters. Fukuoka Stadium, in 1993, Japan also built the Miyazaki Water World, which is 300m long, 100m span, and 38m high, and the opening and closing methods are parallel and overlapping.

Tensile cable structure buildings and tensile membrane structure buildings

In the 1950s, with the emergence of the tension cable structural system, the tensile membrane structural system was also born. The German Pavilion at the Montreal International Expo, completed in 1967, marked the maturity of the tensioned cable structural system.

In the 1972 Munich Olympic venues, the area covered by the cable structures of the stadium, gymnasium, and swimming pool, and the maximum span of the structure was almost three times larger than that of the German Pavilion (22000㎡/8000㎡, 135m/45m).

The Denver International Airport Terminal Building in the United States was completed and put into use in 1994. It is the largest closed tensile membrane structure building in the world. The building has a unique shape. From a distance, it looks like a continuation of the snow-covered Rocky Mountains on the outer edge of Denver, and it also looks like a tent where Indians live. The designer combines the shape with the natural environment and local culture so that people entering and leaving Denver can feel the unique local color.

The Georgia Dome, the roof of the 1996 Atlanta Olympic Stadium, is currently the world’s largest-span dome structure that combines a cable network and a membrane (240×193m). After the project’s completion, many structural experts predicted that this type of structural system would monopolize the roofs of large sports venues in the 21st century.

High-rise steel structure building

After stagnating in the 1940s, high-rise steel structure buildings in the United States revived in the 1950s, and the influence of Mies van der Rohe was supreme. The completion of Chicago’s Hubin Apartments from 1948 to 1951 made Mies’s idea of a glass skyscraper proposed in 1921 a reality.

The real high-rise building with all-glass exterior walls is the Lever Building in New York, completed in 1952. The four glass walls of the Lever Building were impressive and highly praised. It even became the design of high-rise office buildings at that time.

The Seagram Building in New York, completed in 1958, is quite eye-catching. The metal part on its exterior is neither steel nor aluminum but copper. This warm-toned metal material makes the Seagram Building look elegant and unique among ordinary steel or aluminum high-rise buildings.

In the 1960s, Fazler R. Khan of the United States proposed the frame-tube system, which provided an ideal structural form for constructing super high-rise buildings. Systems such as tube-in-tube, multi-beam tube, and diagonal bracing tubes derived from this system have their characteristics, pushing the development of high-rise buildings to a climax.

The World Trade Center in New York, completed in 1972, finally broke the Empire State Building’s 41-year-old world record. It was unprecedented not only in size but also in technological achievement. This project was the first to conduct a model wind tunnel test, use viscoelastic dampers for shock absorption, use profiled steel plate composite floors, etc., significantly impacting subsequent high-rise buildings.

After the 1980s, due to the rapid economic development in Asia, especially the West Coast region of the Pacific Rim, the focus of skyscraper development shifted to this region.

The recently completed Shanghai Jin Mao Tower (88 floors, 420.5 meters) and Kuala Lumpur, Malaysia’s Perzonas Tower (95 floors, 452 meters) illustrate this issue quite clearly.

Steel-concrete composite structure building

Most super high-rise buildings built before and in the 1970s used steel structures, and the proportion of steel-concrete structures increased in the 1980s. In addition to being affected by the building’s use, these changes are mainly due to economic reasons and fire protection requirements.

Kuala Lumpur Pezhongnas Tower, Shanghai Jinmao Tower, Shenzhen Diwang Tower, Shenzhen SEG Plaza, Shanghai Pudong International Finance Tower, etc., all use steel-concrete structures and are particularly worthy of attention.

From the beginning of the 21st century to the present

After mankind entered the 21st century, there has been no breakthrough progress in structural technology in light steel structures, space steel structures, high-rise steel structures, etc. However, steel structures’ technical, aesthetic, and bionic tendencies deserve special attention.

The technical, aesthetic tendency of steel structures

Science and technology are the ladder of progress for human society and architectural development. Changes in technical means will transcend cultural factors such as styles and schools, significantly impact architectural modeling, and change architectural creation concepts and design methods.

One of the technical foundations of high-tech buildings is new structural technology. Architects are pursuing technical performance, but the technical performance of high-tech buildings is by no means exposed to structural parts. Still, it starts from technical aesthetics, clever use, understanding of structures and innovative structural forms, and naturally expressing structure and technology.

In recent years, high-tech architecture has incorporated ideas of ecological aesthetics and paid more attention to regional culture. The content of its technical performance has expanded, and environmental technology and regional culture have also been included in the scope of expression.

The idea of technical aesthetics emphasizes the combination of technology and art and has the characteristics of structural rationality, so it is widely accepted. Mainstream architecture today mainly uses steel structure technology and other high-strength technologies as technical means. It develops along the path of organic integration of technology and art.

Suzhou Museum: The new Suzhou Museum, designed by Mr. Ieoh Ming Pei, is a landmark building that integrates the traditional Suzhou style and modern architectural culture. It reflects the simplicity and heritage of Chinese ink painting and the decorative beauty and plane beauty of Western modern abstract painting.

Bird’s Nest: The Bird’s Nest was the main venue for the 2008 Olympic Games. Its appearance looks like a bird’s nest made of branches. The stadium’s structural system seems to have no rules, but that is not the case. Its structural system is prominent. Here, the hollowing techniques, ceramic textures, brilliance, and warmth of red in traditional Chinese culture are perfectly integrated with the most advanced modern steel structure design.

The entire building is like an enormous container, giving the stadium incredible drama and unparalleled power.

Biomimetic tendencies of steel structures

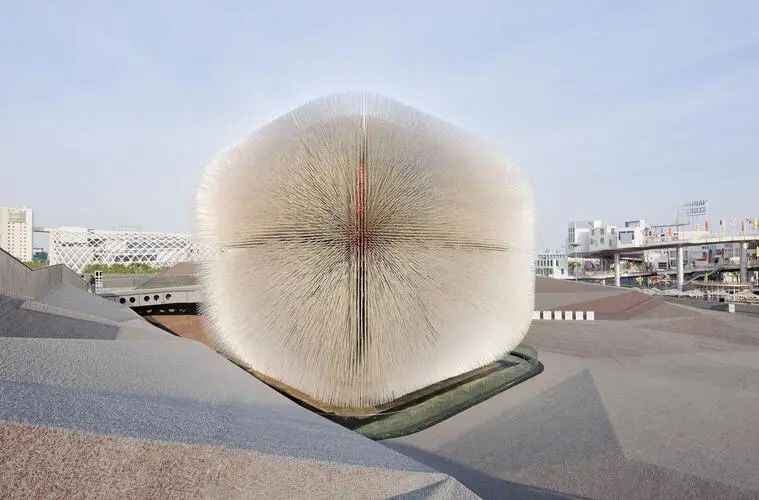

British Pavilion at World Expo: The most charming venue at the 2010 Shanghai World Expo is the British Pavilion, also known as Dandelion and Seed Temple.

Designed by Thomas Heatherwick, it is breathtaking in its creativity and innovation. The British Pavilion is supported by a steel structure system with about 60,000 transparent acrylic poles. They stretch out like a dandelion dancing in the wind. During the day, 60,000 fine acrylic poles guide sunlight into the room; at night, the light is directed outside, lighting up the entire building, creating magical light and shadow that makes people forget to leave.

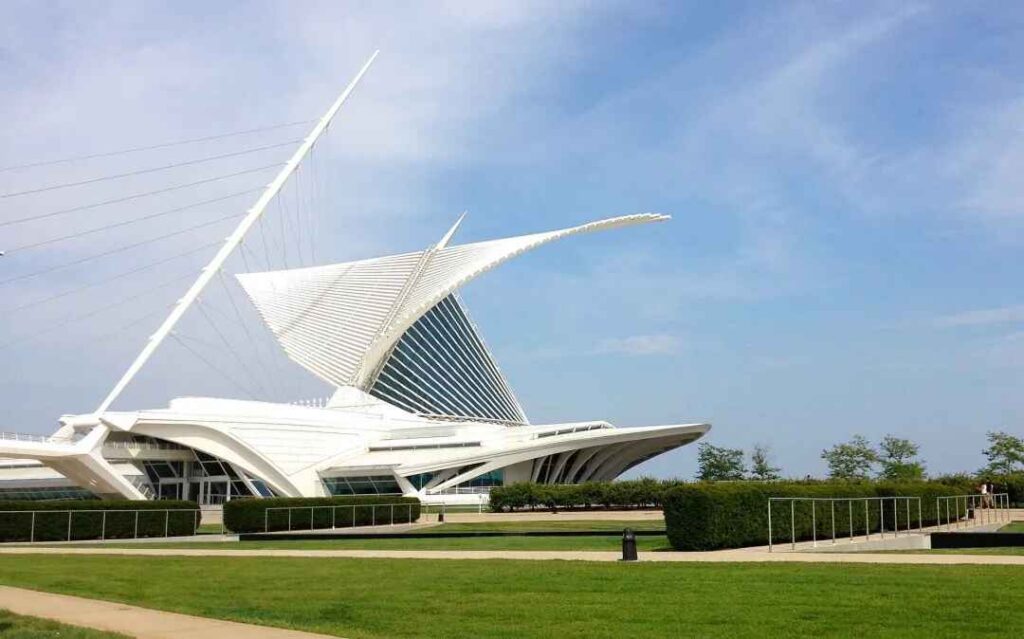

The Milwaukee Art Museum in the United States was designed by Karatawa, who is famous for his bionic structure and strong personality. The Milwaukee Museum of America is one of the most dazzling masterpieces in his architectural career.

The museum’s shape is composed of an 11m-high arch, a glass roof, and a stainless steel frame. The most distinctive shape on the museum roof is the “wing,” like a seagull in flight. This foldable structure, shaped like a bird’s wing skeleton and weighing 115 tons, is a movable solar screen that can be opened or closed according to wind speed and weather conditions.

Sometimes, it slowly unfolds like a wing to shelter the building; sometimes, it closes and retracts to the hyperbolic attached roof. This roof is divided into two parts from the middle. Each part is composed of 36 steel bars. The length of these steel bars gradually decreases from 32m to 8m according to the curve, thus completing this particular roof shape.

Outlook for Steel Structure Buildings

Due to the significant advantages of steel structure buildings, many countries are researching and developing such buildings. Several trends are particularly noteworthy:

Spatial structures mostly replace planar structures.

Many designers believe that we are on the eve of a significant architectural revolution, which will transform the two-dimensional structures of the past into the three-dimensional structures of the present and future.

Processing is developing towards refinement.

The attractive charm of steel structure buildings is inseparable from its precise processing. Steel components and their nodes have apparent stresses, beautiful proportions, and fine transitions, fully demonstrating the delicate and smooth texture of the metal. In this way, the steel structure overcomes the shortcomings of neglecting human feelings and indifferent images and organically combines high technology with high emotions.

Combining steel structure technology with ecological technology

The combination of steel structure technology and ecological technology is an inevitable choice in the context of an environmental crisis. It will inevitably be the main development direction of steel structure buildings for a long time.

Trends in Steel and Concrete Combinations

Steel structures and concrete structures each have their strengths. Comprehensive utilization of the advantages of these two structures has opened up a new way for the development of steel structures and concrete structures.

Statistical analysis shows that the amount of steel used in high-rise buildings using steel-concrete composite structures is about 70% of steel structures, and the construction speed is equivalent to that of all-steel structures. After comprehensively considering factors such as the construction period and the occupied area of the structure, the hybrid structure has comprehensive economic indicators that are better than those of all-steel and all-concrete structures.

More than half of the high-rise steel structure buildings that have been built or are under construction in my country (about 40 buildings) use steel-concrete hybrid structures. The Ministry of Construction and the National Metallurgical Industry Bureau recently promulgated the “Technical Policy for Steel Use in Construction,” which listed steel-concrete hybrid structures as a new construction technology that should be vigorously promoted. It is foreseeable that hybrid structures will be used in high-rise office buildings, schools, and hospitals, and They will be widely used in residential and other buildings.

In Conclusion

The history of steel structure buildings bears witness to the convergence of technological advancement, architectural innovation, and human ambition. From early iron bridges to skyscrapers, steel has reshaped the urban landscape, allowing us to build stronger, taller, and more durable buildings. As material science and engineering continue to advance, steel’s legacy remains a cornerstone of modern architecture, symbolizing the tenacity of our past achievements and the endless possibilities of the future.