A steel frame is a structure made of steel, usually connected by welding, bolting, or riveting steel beams, columns, bracing,…

As a new type of building form, steel structure building has simple force, clear force transmission path, and fast construction. It is widely used in industrial, commercial, and public facilities and other buildings. In this article, we want to share the precautions for steel structure installation.

Steel structure installation for column foot

During the column foot installation, there may be a problem that the bolt cannot be tightened due to the insufficient thread length of the anchor bolt. To prevent such problems, the top of the anchor bolt’s elevation must be reviewed during construction, and the thread length must be sufficient.

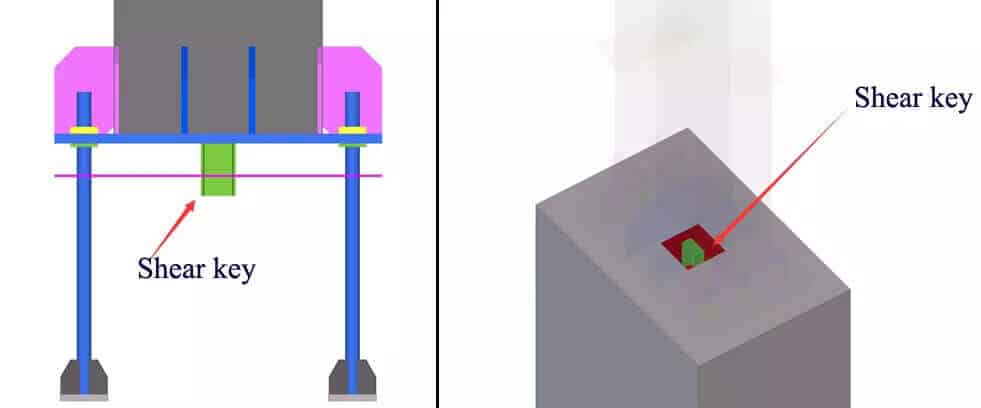

For the column foot with a shear key at the bottom of the column, it is necessary to reserve the shear groove according to the size during construction, and there should be no debris such as stones in the shear groove.

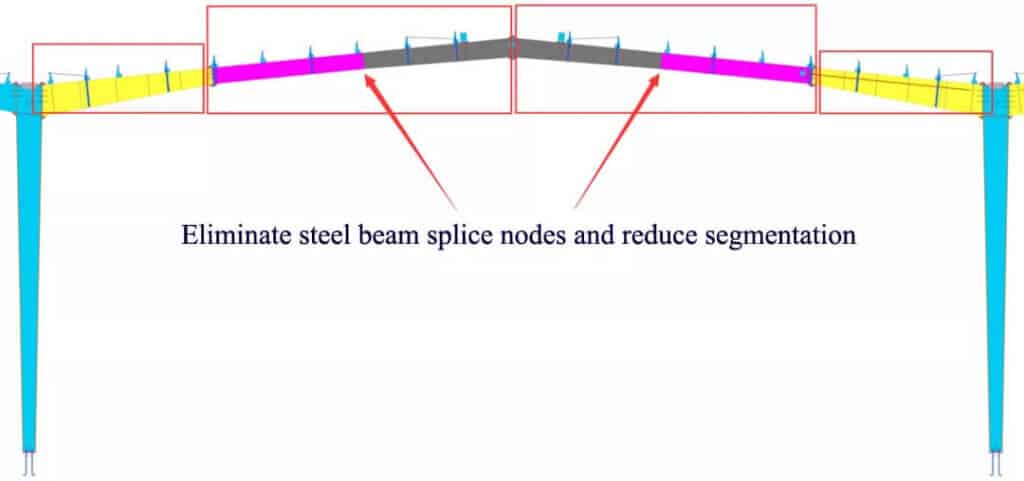

Steel beam segment

The reasonable span of the portal steel frame is about 24-30m, and the steel beam within the reasonable span should not be segmented into more than four sections. Suppose the original design does not consider the convenience of site construction. In that case, the steel beam is divided into six sections when the design is made, and the structural engineer can carry out the verification review according to four sections. The review can greatly reduce the site workload if it is passed.

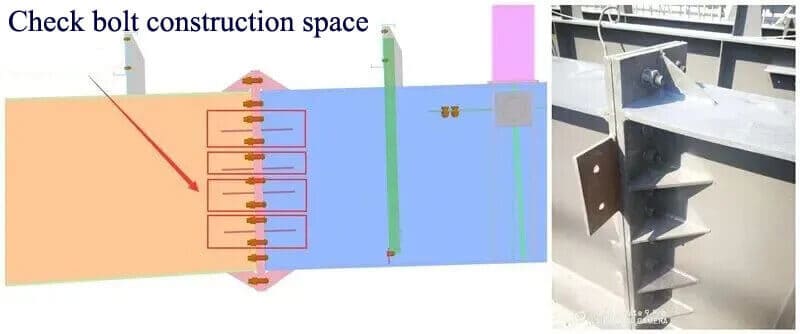

Precautions for splicing bolts

The number of bolts in the beam-column and beam-beam splicing joints is often relatively large, and there is a stiffening plate near the bolts. The bolt space should be reviewed in advance during construction to ensure that the electric torque wrench is smoothly tightened.

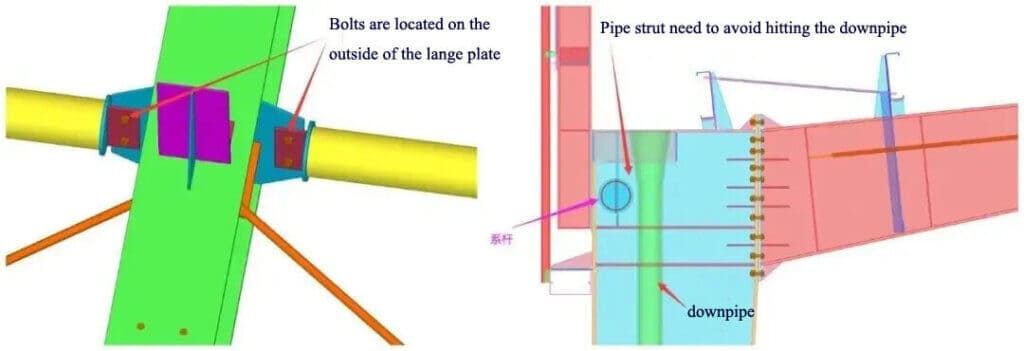

Pipe Strut Installation

The bolts connecting the pipe strut and the beam and column should not be in the beam and column’s flange. Otherwise, it is not easy to construct; besides, the pipe strut on top of the column top with a gutter often needs to be moved to the outside to ensure that the downpipe can fall smoothly.

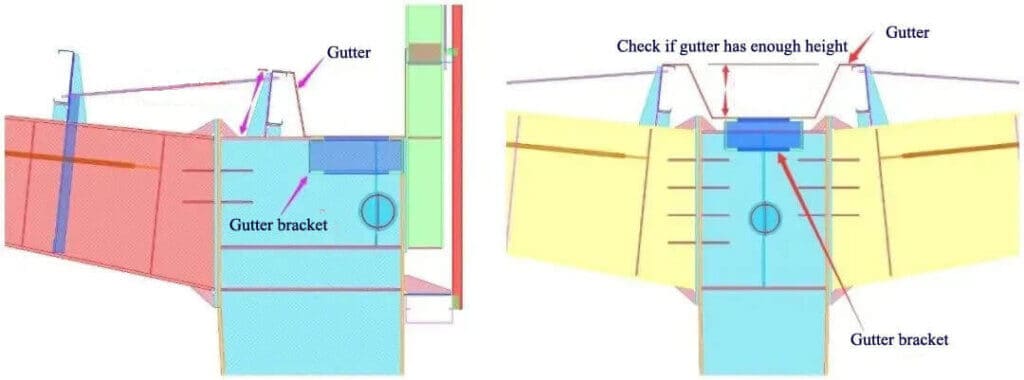

Gutter

Gutters are an important part of preventing water leakage in the steel building. Before the fabrication of the steel structure, the engineer should verify the purlin’s height to meet the gutter’s depth requirements and whether the gutter’s height meets the drainage requirements for the middle gutter. Besides, consideration should be given to the need for gutter brackets to consider the gutter thickness and drainage.

Steel structure installation for crane beam

When installing the crane beam, in addition to paying attention to whether the net distance between the top of the crane and the roof beam has enough space, it should also be noted that there is a column bracing bay. The bolts at the beam-column connection nodes should be high-strength bolts or ordinary bolts, and there is no column bracing in the bay; the bolts adopt ordinary bolts.

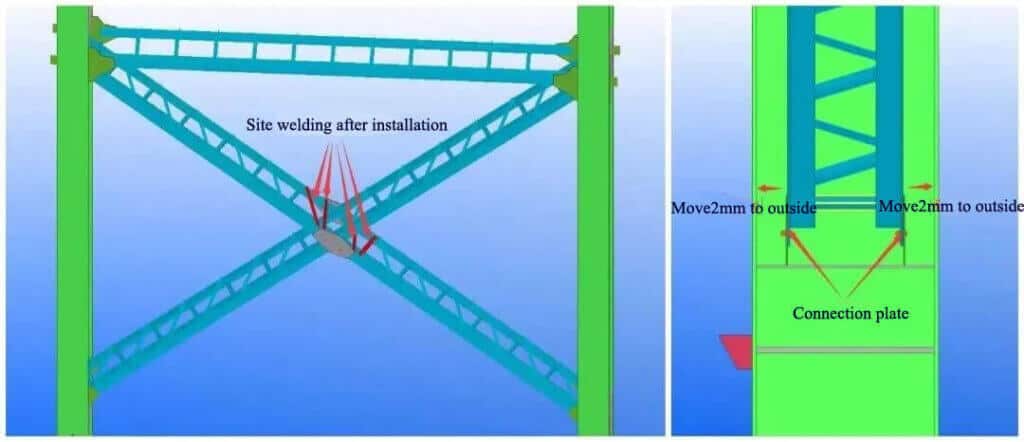

Column brace installation

For the column brace composed of angle steel, when installing a short brace, to ensure a smooth installation, the angle steel strips near the connecting plate of the brace should be welded on-site after installation; the connection plate in connecting the bracing to the steel column should also be moved outward by 2mm each.

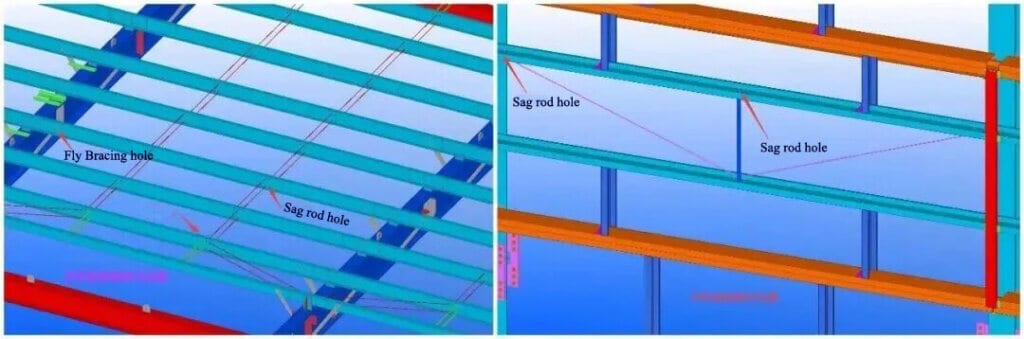

Steel structure installation for Purlin

There are often a large number of wall girts and roof purlins in portal rigid frames. To minimize component numbers and reduce construction difficulty, all the holes for sag rod, flange bracing should be set and unified.

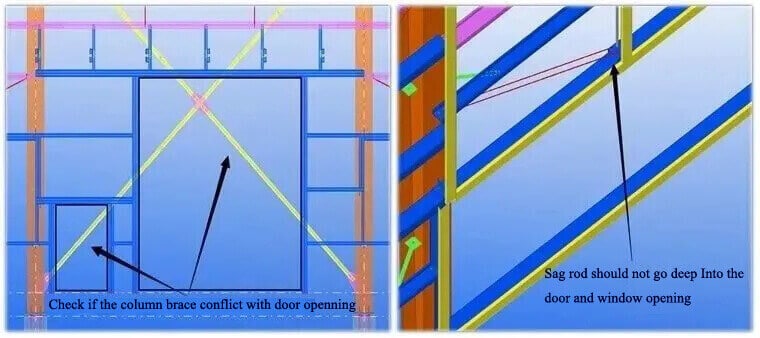

The installation of door and window openings

In the construction drawing review stage, in addition to checking whether the structure is consistent with the positions of the doors and windows, reserved openings, gutters, and cornices in the building drawings, it is also necessary to check whether the door openings conflict with the column bracing; besides, the sag rod should not go deep Into the door and window opening.

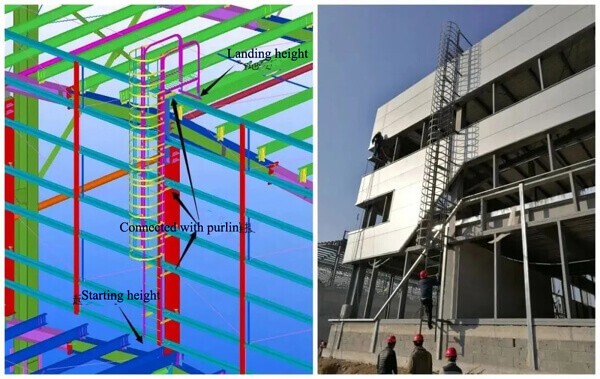

Steel structure installation for Ladder

As an important subsidiary structure of the steel structure building, the maintenance ladder must consider the starting height, landing height, and the connection with the roof purlin. Since the ladder has a thin cross-section and is easy to deform, the workers must pay special attention to the ladder’s protection before installation.

Common mistakes for steel structure installation

The quality of steel structure installation is also one of the important factors determining the quality of steel structure building. Various errors are prone to occur in the installation of steel structures, and errors should be avoided as much as possible during the installation process because errors in the installation of steel structures will lead to rework and waste construction time. Moreover, installation errors will directly increase the project budget cost and affect the reputation of the builder. Of course, it is also very wise to choose an installation team with rich installation experience. They will use reasonable methods and construction experience to avoid many mistakes.

1. Start construction without preparation

It is necessary to make preparations before starting construction to facilitate the normal progress of the subsequent installation process.

- First, cleared out a large area in and around the construction site to allow the unloading and storage of parts and components.

- Allow sufficient time for the foundation concrete to be cured before the load-bearing project. Even if the weather is clear, the concrete foundation needs at least one week of curing time before the load is applied.

- Provide sufficient roads and passages for steel transport vehicles, construction equipment, and workers. Pay attention to marking all public facilities, especially overhead wires and underground cables.

If you are eager to build initially but are not prepared, it will cause potential safety hazards to be buried from the beginning. For example, lack of access may lead to steel structure installation accidents, steel transportation, and lifting construction delays. In addition, if the foundation is not well-stabilized, then the anchor bolt connection will be unstable.

2. Install directly without following requirements

Some workers believed that they knew enough and did not follow the designer’s instructions to install and install in the way they thought, resulting in rework inconsistent with the design drawings. The installation team should communicate with the steel structure designer before installation and installation in strict accordance with the designer’s requirements.

3. Ignore safety regulations

The construction industry’s work-related injuries and accidents are much higher than in other industries. Therefore, steel structure installation must also comply with safety regulations and use appropriate safety equipment to avoid accidents. Every engineer, contractor, subcontractor, and site worker involved in a steel structure project is responsible for complying with all safety procedures and ensuring that everyone receives information. In addition, the contractor should purchase appropriate insurance for all on-site construction workers.

4. Do not use cranes or forklifts for unloading

Some installation teams may avoid unloading with cranes or forklifts to save costs. However, most of the components of steel structure engineering are very cumbersome. Without suitable equipment, there is no good way to move the components safely and efficiently on the construction site by relying on manual labor alone. Furthermore, if other tools are used, the steel components may be damaged, bent, and scratched, which will cause unnecessary trouble for the future maintenance of steel structures.

5. On-site cutting and splicing components

Before construction, try to ensure that each component has the correct size and shape and avoid on-site cutting and modification. Because cutting and splicing the main components will not only endanger the stability of the building but also cause oxidation and rust on the beams, columns, and panels. Because on-site cutting and touch-up on-site cannot ensure that the touch-up surface is dried in time.

6. Incorrect installation of fasteners

Fastener installation in steel structures is the key to stable roof installation. Fasteners are not difficult and should be properly tightened in the corresponding holes. Pay special attention to correct tightening tools during construction and correct tightening of high-strength bolts. Do not overtighten or loosen them.

7. Random stepping on roof panels

Workers should not walk around where the steel roof slab is not connected to the purlin. Because walking on a panel that is not completely safe will damage the panel and cause injury to workers. It is forbidden to step on skylights and translucent panels. If the panel is fixed, you should try to walk on the panel at the purlin. In addition, do not walk on the panel under the eaves to avoid deformation of the panel caused by stepping.