Steel Workshop Building In Bolivia

Havit Steel process the design and fabricated Steel Workshop Building In Bolivia. The steel workshop building located in La Paz used to produce glass. Bolivia is situated in South America, and its official language is Spanish. The country is dominated by plateau topography, with an average altitude of over 3000 meters, making it the highest average altitude country in the world. Among them, La Paz has an altitude of more than 3,600 meters, making it the world’s highest capital.

Description of Steel Workshop Building In Bolivia

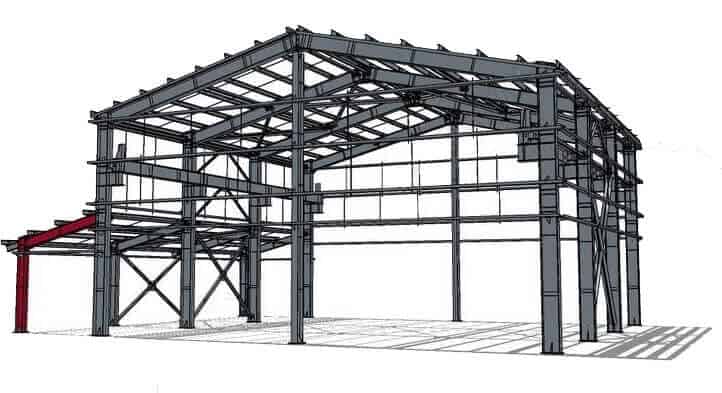

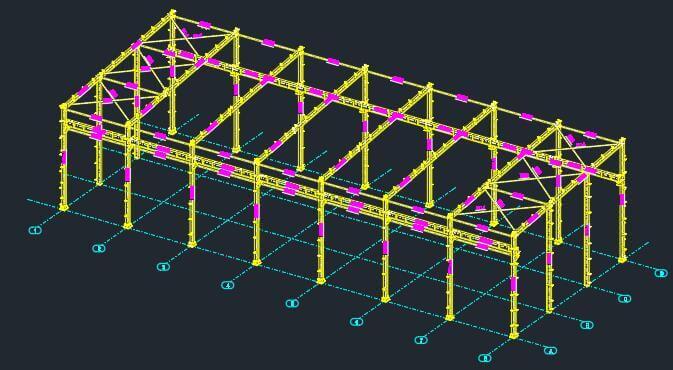

The customer’s original workshop building is relatively old, so he plans to build a new factory with a steel structure to expand production. The steel workshop building area is about 600 square meters, length: 40 meters, width: 15.5 meters. The roof of the workshop building is a single-slope structure, with a height of 8.65 meters to 10.15 meters and a 5-ton crane inside the factory building.

The surfaces of all main structures of the plant are all hot-dip galvanized, which has a good anti-corrosion effect and increases the service life.

Hot-dip galvanizing anti-corrosion technology is currently the most advanced and widely used technique, and it is also the steel anti-corrosion method with the best use effect and economic benefits. The primary process is first to immerse the steel components to galvanized into a molten zinc bath, and then plate them to form a pure galvanized layer on the surface of the steel, and an alloyed zinc coating on the secondary surface, thereby playing a role in steel corrosion.

The components of the steel workshop building

Anchor bolt: used to fix steel column

The column foot of the factory building with crane is just connected.

Steel column and roof beam: Q345B welded H-shaped steel.

Crane beam: Q345B welded H-shaped steel.

Column Cross Bracing: Angle steel

Roof bracing: round steel

Roof purlin: Z-shaped steel.

Wall girt: C-shaped steel

Roof and wall panel: 50mm glass wool sandwich panel.

Features of Steel Structure Workshop:

1. Lightweight

Compared with other building materials such as concrete, masonry, and wood, steel structure has much higher strength, so structural members are light and small.

2. Large span:

Although the density of steel is higher than that of other building materials, its strength is very high, and it can make into a structure with a larger span.

3. The construction period of the steel workshop building is short.

The steel components are prefabricated in the factory, and only need to be assembled on-site without secondary processing. All steel components connected by bolts, which are easy to install and fast in construction.

4. The steel workshop building is easy to move, and the recycling is pollution-free.

Because bolts connect the steel components, it is easy to disassemble. 90% of the materials can recycle after remove, which reduces environmental pollution.

How to Optimize the Design of Steel Structure Workshop

The design of steel structure workshop is tailored to its use function to ensure smooth material flow and efficient use of internal space. The operational requirements of the workshop determine its size and layout. The site selection of a steel structure workshop should fully consider the local terrain, traffic, and environmental factors. A strengthening design must be adopted if the workshop is located in an area with strong winds or frequent earthquakes. In addition, the design of steel structure workshops must comply with building specifications to ensure that the structure meets the load requirements and improves the stability and safety…

Steel Structure Building

As a new type of building system, steel structure building breaks through the boundaries of…

Steel Workshop Building

Steel workshop Building is a steel structure buildings that house production equipment. They are widely…

Steel Warehouse Building

The steel warehouse buildings designed and processed by Havit Steel provide customers with ideal storage…