Steel structure splicing includes splicing in the workshop and on-site. The splicing methods include welding and bolting. We should implement…

1. What is a Steel Structure Workshop Building

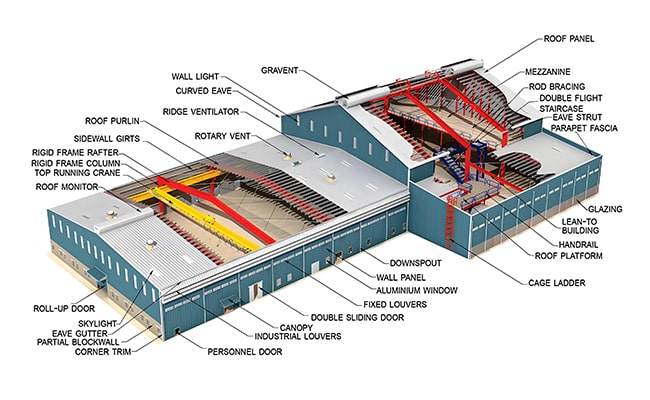

Steel structure workshops are modern industrial facilities composed predominantly of prefabricated steel components. Their widespread use across sectors such as manufacturing, logistics, warehousing, and material processing stems from their ability to deliver durability, flexibility, and efficiency. Compared with conventional concrete buildings, steel workshop buildings offer faster project turnaround times, more cost-effective construction, and superior resilience against seismic events, wind pressures, and corrosion.

Depending on the specific operational needs, these workshops can take the form of single-story layouts—ideal for streamlined production—or multi-story configurations designed to optimize vertical space. In either case, steel structures provide a highly adaptable solution that evolves with industrial demands.

This article outlines the core engineering elements, on-site construction procedures, design strategies, and long-term upkeep recommendations essential for planning and managing high-performance steel workshop facilities.

2. Core Technical Features of Steel Workshop Buildings

2.1 Foundation Systems and Structural Anchoring

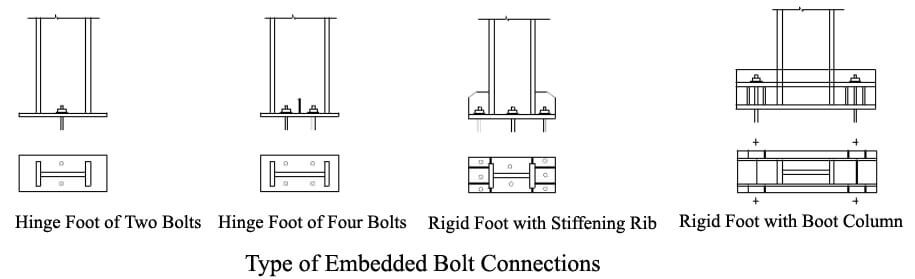

A solid foundation forms the structural backbone of any steel workshop. Reinforced concrete footings, together with anchor bolts embedded into the subgrade, ensure that vertical loads are reliably transferred and that lateral forces from earthquakes or wind events are effectively resisted.

2.2 Primary Framework: Q355B Steel

The main structural elements—typically H-section welded beams and columns—are manufactured using Q355B steel. This material is valued for its high tensile strength, weldability, and ability to withstand demanding load conditions, particularly in large-span workshops.

2.3 Secondary Structural Systems

Roof and wall purlins, fabricated from cold-formed C- or Z-sections, act as secondary members that stabilize the frame and support external cladding. Bracing systems—roof, wall, and diagonal—contribute to both local and global rigidity, ensuring structural equilibrium under dynamic loads.

2.4 Roofing and External Envelope

Exterior envelopes typically consist of color-coated steel sheeting or composite sandwich panels, featuring EPS, polyurethane, or rock wool infill. These layers provide thermal insulation, fire resistance, and weather durability, tailored to the operational and environmental context of the facility.

2.5 Architectural Elements and Fastening Systems

Steel workshop buildings are equipped with functional components such as insulated roll-up doors, access panels, ventilation hatches, and aluminum-frame windows. All structural and auxiliary elements are secured using corrosion-resistant fasteners—including high-strength bolts and self-tapping screws—to guarantee long-term performance.

Read More: Steel Building Specification

3. How to Build a Steel Structure Workshop On-site

The assembly of a steel structure workshop typically proceeds through the following sequence:

Primary Frame Installation: Steel columns and beams are lifted and secured in place, ensuring precision alignment through bolted or welded joints.

Integration of Secondary Members: Purlins, bracing, and girts are installed to complete the structural framework.

Roof Panel Placement and Insulation: Roof cladding, along with thermal and waterproofing layers, is mounted in line with climate requirements.

Wall Cladding Installation: Wall panels are affixed, including pre-cut openings reinforced for windows and doors.

Detailing and Finish Work: Flashings and trims are added around joints—such as corners, ridges, and eaves—to prevent water ingress and refine the building’s visual profile.

Read More: Steel Structure Building Installation

4. Height and Span Considerations in Steel Structure Workshop Design

4.1 Functional Significance of Height and Span

In industrial steel workshop design, the vertical and horizontal dimensions of a structure are not mere geometric parameters—they fundamentally shape the building’s utility. An appropriately calibrated height facilitates the integration of overhead cranes and the installation of large-scale machinery, while an optimized span enables open floor layouts, free of obstructive interior columns. These factors directly influence production flow, spatial efficiency, and long-term operational costs, making them central to both design feasibility and functional success.

4.2 Industry-Specific Height Recommendations

The required floor-to-ceiling height varies significantly across sectors, reflecting differences in equipment size, workflow structure, and regulatory compliance. Based on prevalent industry practice:

Heavy Industrial Applications (e.g., metallurgy, mechanical assembly): Minimum 10 meters, to accommodate heavy-duty equipment and bridge crane systems.

Packaging and Advanced Material Processing: Often ≥12 meters, due to specialized vertical machinery and loading requirements.

Light Manufacturing (electronics, furniture, plastics): Typically around 8 meters, offering sufficient clearance for mid-scale production lines.

Standard Use Cases: Where no large equipment is involved, 6–8 meters is generally adequate.

These figures should be adapted in consultation with engineering teams to reflect specific site constraints and process layouts.

4.3 Span Classification and Use Cases

The horizontal span—defined as the distance between two opposing side walls—determines the building’s interior openness. Contrary to common confusion, span differs from column spacing, which refers to intervals along the building’s longitudinal axis. Typical classifications include:

Light-Duty Workshops: 12–18 meters, often sufficient for warehousing and small-scale assembly.

Medium-Sized Facilities: 12–21 meters, accommodating larger equipment and moderately complex layouts.

Heavy-Duty Workshops: 15–24 meters, essential for operations involving overhead lifting or large machinery.

Extra-Wide Structures: 24–36 meters, reserved for specialized sectors such as shipbuilding or aviation component assembly.

4.4 Balancing Structural Efficiency and Economic Constraints

While broader spans offer the advantage of uninterrupted working space and flexibility in equipment placement, they also introduce structural challenges and increased material demand. Therefore, span design must strike a pragmatic balance between economic feasibility and load-bearing capacity. The involvement of structural engineers during early design stages is essential to achieving a safe and cost-effective layout.

5. Single-Story Steel Workshop Buildings: Efficiency and Flexibility

5.1 Operational Benefits

Single-level steel workshops are especially well-suited to industries requiring open floor plans without internal supports—such as automotive assembly, agricultural processing, and logistics warehousing. Their clear-span design promotes efficient layout and unhindered equipment movement.

5.2 Critical Design Considerations

Effective planning of bay spacing, eave height, natural light distribution, and airflow is essential. Features like ridge skylights or translucent roof panels can significantly reduce artificial lighting needs while improving working conditions.

5.3 Modular Planning and Load Coordination

Modular design, using standard bay intervals of 6 to 9 meters, allows for simplified fabrication and predictable structural performance. Regional snow loads, wind patterns, and seismic activity must guide adjustments in slope, span, and reinforcement.

6. Multi-Story Steel Workshop Buildings: Vertical Optimization

6.1 Strategic Application

In dense urban zones or where spatial separation between process stages is desirable, multi-story steel workshops offer a smart alternative. Typical applications include precision electronics, clean manufacturing environments, and vertically segmented research labs.

6.2 Structural Integrity and System Integration

Designing for vertical expansion necessitates careful consideration of load paths, inter-story bracing, and shear wall placement. Structural safety relies on the integration of braced frames, composite slabs, and vertical circulation systems such as stairwells and service shafts.

6.3 Functional Advantages

Optimized land use in footprint-limited sites

Clear zoning between operational and support functions

Faster construction timelines compared with traditional framing

Built-in support for elevators, mechanical risers, and HVAC shafts

Read More: Steel Structure Multi-story Building

7. Maintenance Guidelines for Steel Structure Workshops

7.1 Electrical System Safety

As the building’s steel frame is conductive, electrical installations must be insulated from the structure. Cables and lighting fixtures should be mounted using non-conductive brackets and routed through sealed conduits.

7.2 Periodic Repainting and Corrosion Monitoring

After five years of operation—especially in exposed or coastal locations—steel elements should undergo repainting and anti-corrosion treatments. Areas most prone to early deterioration, such as base plates and exterior bracing, should be prioritized.

7.3 Caution on Structural Alterations

Facility managers should avoid making layout or load-bearing changes without professional analysis. Modifications to beams, columns, or bay spacing must be structurally verified to preserve building integrity.

7.4 Roof and Drainage Cleanliness

Seasonal buildup of organic debris can obstruct drainage and accelerate corrosion. Routine inspection and cleaning—particularly after storms—help maintain structural longevity.

7.5 Surface Damage Repair

Dented cladding, chipped paint, or exposed base metal should be repaired promptly to avoid long-term degradation caused by moisture ingress or UV exposure.

7.6 Exterior Surface Cleaning

Cleaning intervals should match the site’s environmental exposure. Gentle, non-acidic detergents and soft applicators are recommended to prevent damage to protective coatings.

8. FAQs About Steel Structure Workshop

1. What is the typical service life of a steel workshop building?

With regular upkeep and proper coatings, service life commonly exceeds 50 years.

2. How long does construction take?

On average, a medium-sized single-story facility can be erected within 2–6 months, depending on project scope.

3. Are these buildings suitable for snow-prone areas?

Yes. Adjustments in roof pitch, load design, and bracing allow compliance with snow load codes.

4. Can steel workshops be expanded or relocated?

Absolutely. Modular construction allows for future expansion or site relocation with minimal rework.

9. Partner with Havit Steel: Build Smart, Build Strong

Whether you are envisioning a streamlined single-story or a sophisticated multi-level workshop, choosing an experienced design and fabrication partner is key. At Havit Steel, we provide end-to-end solutions—from custom engineering to on-site delivery—ensuring your project is executed with precision and reliability.

📩 Get in touch today for a free consultation and quotation. Let’s build your next-generation steel facility—efficient, durable, and future-ready.