In the construction of modern storage facilities, steel structure warehouses have become one of the mainstream building forms due to…

Steel structure welding is the primary connection method of steel structure: to melt the welding rod and steel partially by the heat generated by the electric arc, and then condense into a weld by cooling, thus connecting the welded parts to one.

Steel Structure Welding

Steel structure welding plays an essential role in the manufacturing and installation process, the quality of steel structure welding directly affects the appearance, and also plays a vital role in the strength of steel structure building.

Steel Structure Welding Methods

1. Shielded Arc Welding (SMAW)

Shielded Arc Welding achieves welding by heating the metal with an arc between a coated electrode and the metal to be welded. The electric current generates the arc between the electrode and the workpiece, providing heat energy to melt the parent metal, filler metal, and the coating. As the arc moves, the weld metal gradually cools and solidifies to form a weld and is covered with a layer of slag on the surface. The key to shielded arc welding is the electrode, which consists of a metal core, an outer layer of granular flux, and a binder. Carbon steel and low-alloy steel electrodes usually use a low-carbon steel core, and alloying elements are introduced through flux, an economical alloying method.

Features:

- The equipment is simple and inexpensive, and it is easy to operate;

- The types of welding rods are diverse and highly adaptable;

- With the improvement of welding rods and equipment, the welding quality is stable;

- The welding speed is slow, and the efficiency is low;

- The welding slag needs to be cleaned after welding.

2. Gas shielded arc welding (GMAW)

Gas shielded arc welding (also known as metal arc welding) uses the arc heat between the welding wire and the workpiece to melt the base material and the welding wire through the welding torch to complete the welding. A notable feature of this method is that the shielding gas used in the welding process is also delivered by the welding torch.

These gases can be inert gases (such as argon, helium) or non-inert gases (such as nitrogen, oxygen or carbon dioxide). In most cases, carbon dioxide is used as a shielding gas because it is cheaper than inert gases. The electrode used in gas shielded arc welding is a solid wire.

Features:

- High production efficiency;

- No welding slag is required during welding, and no slag removal is required after welding;

- Good weld visibility, the welder can easily observe the arc and molten pool, and improve control accuracy;

- Sensitive to airflow and wind, the shielding gas is easily blown away, and it is not suitable for open-air environments;

3. Flux-cored arc welding (FCAW)

Flux-cored arc welding is similar to gas shielded welding, except that it uses a tubular wire filled with flux instead of a solid wire used in gas shielded welding. The wire is fed through a welding torch and an arc is created between the wire and the workpiece. Similar to manual arc welding, the weld is covered with a layer of slag. Depending on the type of wire, the flux-cored wire can provide shielding gas through internal flux or require an external shielding gas.

Features:

- High production efficiency, the most efficient among manual welding;

- Whether or not shielding gas is used, the flux provided by flux-cored wire makes the parent material more tolerant of contamination;

- A large amount of smoke is generated during welding;

- Slag needs to be cleaned after welding;

- The equipment is more complex than manual arc welding.

4. Gas tungsten arc welding (GTAW)

The most notable feature of gas tungsten arc welding (GTAW) is that the electrode does not consume during the welding process. It uses pure tungsten or tungsten alloy electrodes that can withstand extremely high temperatures. The current passes between the tungsten electrode and the workpiece to establish an arc. When filler metal is required, additional filler material must be added, usually by hand or mechanical wire feeding.

The arc and metal area are protected by an inert gas (such as argon), and no flux is used, so there is no need to clean the weld slag. Tungsten inert gas welding is widely used to weld almost all materials, especially for applications requiring high precision, such as aviation, food processing, and oil pipelines.

Features:

- High weld quality and excellent appearance;

- Because there is no flux, the welding process is clean and there is no need to clean the weld slag;

- Suitable for welding extremely thin materials;

- Can weld almost all metals;

- No filler material is needed when welding;

- The production efficiency is low, and it is the slowest of all welding methods;

- Low tolerance for contamination, and the parent material and filler material need to be carefully cleaned before welding;

- High welder skill requirements;

- Tungsten inclusion defects are prone to occur.

5. Submerged Arc Welding (SAW)

Submerged arc welding is performed by feeding a solid wire into the welding area and completely covering the arc under the flux layer. This method is very high in deposition efficiency and is currently one of the most efficient welding methods. During welding, the flux not only protects the molten pool from air, but also plays a metallurgical role. During welding, the weld will be covered with a layer of welding slag.

Features:

- High deposition efficiency;

- No visible arc during welding, welders do not need to wear protective glasses or heavy protective clothing;

- Less smoke generated;

- Suitable for flat welding and horizontal welding, limited welding position;

- The flux needs to be heated and cannot be exposed to moisture;

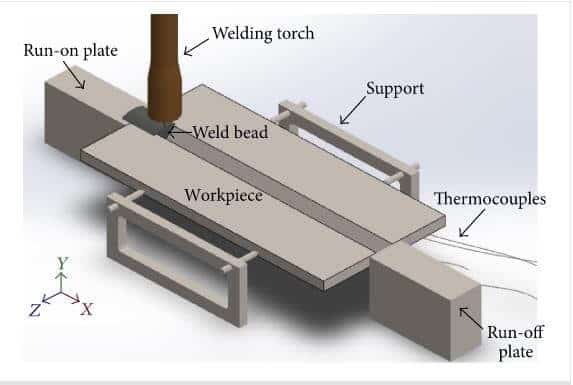

Steel Structure Welding Materials

The main tools used in the steel structure welding are welding electrode and run on plate. When selecting the welding rod, its model must be strictly following the design requirements. Then the welding rod should be baked according to the relevant instructions and placed in a heat preservation barrel for later use. Besides, in the welding process of steel structure buildings, it is strictly prohibited to use some electrodes with rusty cores, and acid and alkaline electrodes must not mix. Finally, when welding important parts of steel structure buildings, it is suitable to choose alkaline electrodes. When the welded steel structure parts need to be grooved, the arc starting plate needs to use, and the material selection of the arc starting plate must be the same as the material of the welded part.

Main tools

The welding tools in steel structure welding mainly include electrode holders, electrode insulation barrels, ovens, and electric welding machines.

Welding conditions and requirements

Steel Structure Welding at low temperatures will cause rapid heat loss. For this reason, when the thickness of the steel reaches a certain level, the multi-layer welding process technology can be used appropriately. Besides, to prevent the rapid decrease of temperature, when welding a particular gap, it must be completed at one time to avoid the phenomenon of welding interruption. If a disruption occurs, it should handle adequately. Finally, in windy and snowy weather, welding should avoid as much as possible. If welding is indeed required, tents should set up, and then the steel structure should be welded indoors. At the same time, the welding process must ensure that the wind speed is within the appropriate limits. After the welding completed, proper materials should use to cool the welded objects slowly.

Reasons for Steel Structure Welding Deformation

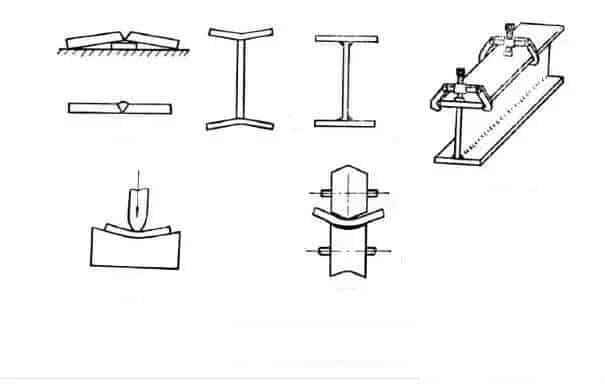

1.The main types of welding deformation

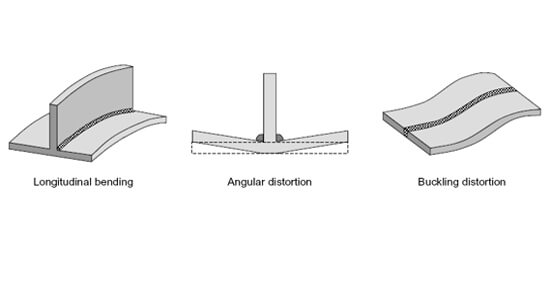

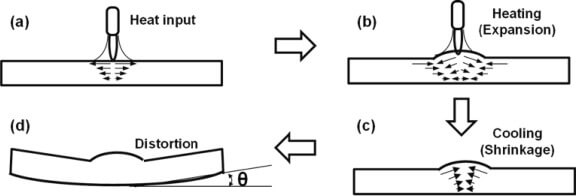

Steel structure welding deformation mainly refers to the strain of the steel structure caused by high temperature during welding and the residual deformation problem that occurs in the structural steel member after the welding completed. Among the above two types of welding deformation, the most affecting welding quality is the residual welding deformation. The influence of residual welding deformation on steel structure buildings divided into overall and local distortion, and according to the shape characteristics of the deformity, it split into angular distortion, longitudinal bending, and buckling distortion, etc. Local deformation includes angular distortion and longitudinal bending, and overall strain also includes buckling distortion and so on. In the steel structure welding process, the most likely type of deformation is total deformation.

2.Reasons for welding deformation

The rigidity of the steel structure is undoubtedly one of the main factors affecting the welding deformation. The stiffness of the steel structure is mainly for the resistance of the structure to deformation such as bending and stretching, and the rigidity of the steel structure depends mostly on the steel The size of the structure, cross-sectional shape. Besides, the location and number of welding joints also affect the degree and condition of welding deformation to a certain extent.

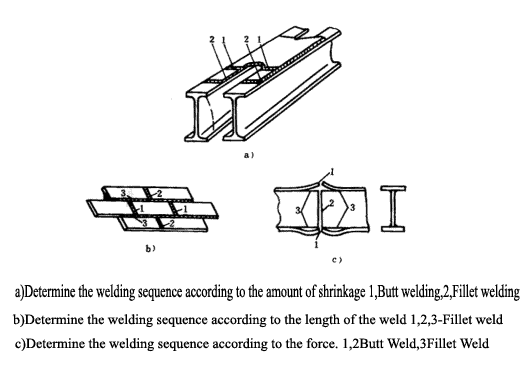

When the rigidity of the steel structure cannot reach a certain standard, the symmetrical position of the steel structure used as the welding joint. If the welding sequence is reasonable, the structure can only produce linear deformation, and it is impossible to produce bending deformation. Finally, the welding process also affects the degree of welding deformation to some extent. For example, when the welding current is large, and the welding speed is slow, it will cause more severe welding deformation. For this reason, in the process of welding steel structures, we must customize the objective and reasonable welding process measures and methods.

Deformation prevention work caused by steel structure welding process

Structure Control of Welding Nodes

To further avoid and improve the welding deformation, we should pay attention to the following aspects when designing the welded joints of the steel structure:

a. First, the number and size of the welds should control. When the steel structure has the problems of a large number of welds and large quantities in the welding process, it will provide more possibilities for welding deformation. For this reason, when designing the welded joints of steel structures, the number and size of welds should be controlled to a certain extent as possible to improve the welding deformation further;

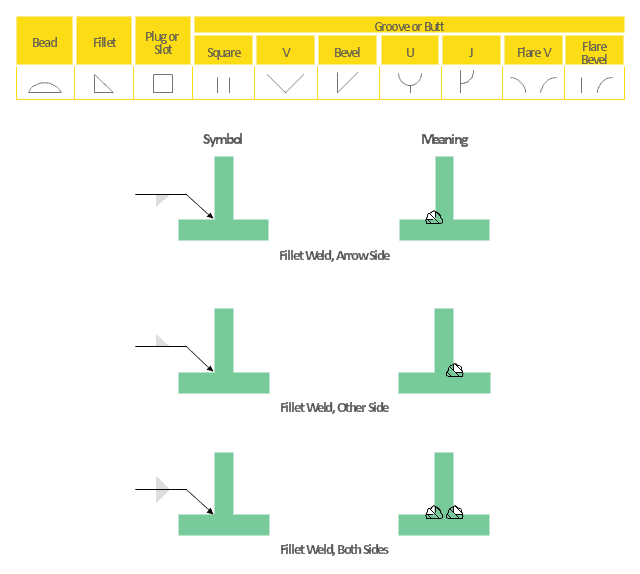

b. Secondly, the appropriate size and shape of the weld groove should select as much as possible. The reasonable and scientific selection of the size and shape of the weld groove can not only ensure the load-bearing capacity of the steel structure to a certain extent, but also reduce the cross-sectional area to a certain extent, and thus control the amount of welding deformation effect;

c. Besides, in the welding process of steel structures, the position of the welding node should be as symmetrical as possible in the cross-section of the object. For the selection of the welding node of the neutral axis, the welding node should be as close as possible to the neutral axis, and at the same time, avoid being in or close to the high-stress area.

d. Finally, the choice of node forms should be as rigid as possible. At the same time, the nodes should not set at multi-directional intersections. Only in this way can the welding deformation due to the high-temperature concentration and stress concentration of the weld be avoided.

Improvement of the welding process of steel structure building

The improvement of the welding structure of the steel structure plays a vital role in the development of the welding deformation. Its specific operations mainly concentrated on the following different aspects:

a. First, the welding sequence selected during the assembly and welding of the steel structure. Regarding the construction and manufacture of steel structures, relevant personnel should strictly follow the applicable regulations and requirements to operate at the standard level. Only in this way can we ensure the corresponding weight-bearing pressure to a certain extent, and then better meet the needs and standards for component assembly. In the welding process of steel structure, the welding of small welding components completed at one time, and then the appropriate welding sequence selected for construction. For some relatively large steel structure welding and assembly, the minor components welded first, and then the corresponding assembly and welding work. To prevent the deformation of the elements during construction, the selection of component models must comply with the relevant regulations and requirements. Besides, excessive forced force splicing should be avoided as much as possible during assembly. Finally, in the process of component welding and construction, the heat uniformity and temperature appropriateness of the welded joint should be maintained as much as possible to prevent welding deformation due to uneven heat.

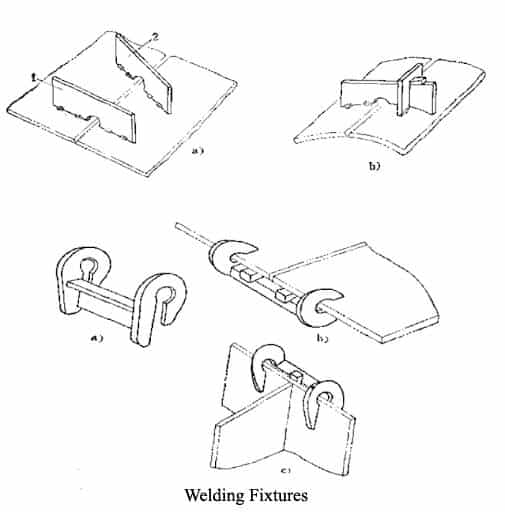

b. Secondly, the corresponding anti-deformation work done. During the welding process of the steel structure, due to the shrinkage principle after cooling, an individual shrinkage reaction will occur in the weld, which reduces the original size of the component to a certain extent. For this reason, in the welding process, people often use anti-deformation to further compensate for the deformation problem caused by thermal expansion and contraction. The anti-deformation method is to artificially generate a specific deformation of the component in the early stage of the welding process. The deformation direction is opposite to the later welding deformation direction, and the degree of distortion is the same as the following deformation degree.

c. Finally, we must have corresponding welding fixtures. For the welding of some more significant components, not only need to have a relevant welding platform but also to prepare corresponding welding fixtures to fix its parts better.

Conclusion:

Steel structure welding is an essential part of steel structure manufacturing, and the welding quality directly affects the strength and appearance of the structure. Different welding methods have their own characteristics. Choosing appropriate welding processes and control measures can help improve welding efficiency, reduce deformation, and ensure the stability and durability of steel structures.