A steel frame is a structure made of steel, usually connected by welding, bolting, or riveting steel beams, columns, bracing,…

As a typical construction and treatment method for steel structures, the level of welding construction is constantly improving, but welding deformation often occurs. Studying steel structure welding deformation and correction can better improve the actual effect of steel structure construction. This paper begins the research of this subject by introducing the classification and causes of welding deformation of steel structures.

Classification and Causes of Steel Structure Welding Deformation

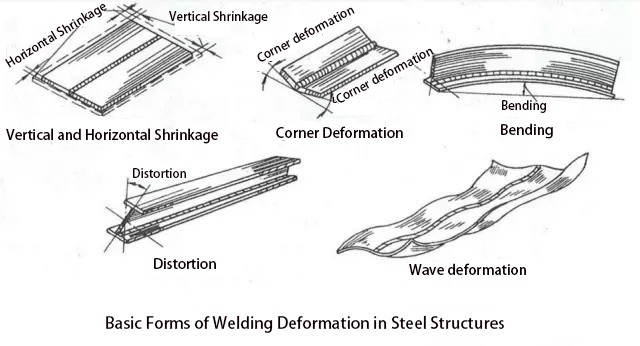

The main factors affecting steel structure welding deformation are the welding process, position, and method. For steel structures, combined with their deformed appearance, steel structure welding deformation can be divided into the following categories:

Steel Structure Welding Deformation can be divided into the following categories:

Corner deformation.

When welding steel structures, the plane welds affect the steel components, resulting in angular displacement. The reason is that shrinkage and deformation occur in the relevant welds along the plate thickness direction in the steel structure. In addition, if the welding sequence is incorrect Or the operator does not use a better welding method, it will lead to corner deformation.

Side deformation.

When the operator welds two steel structures because the specific heat received by the two is different, there will be a particular difference in the length and height of the two steel structures, resulting in misalignment, that is, misalignment. Because the rigidity of the two is different, the shrinkage deformation is also other, leading to misalignment deformation.

Bending

After the steel structure is welded, deformation occurs in adjacent welds, resulting in no identical deformation between adjacent welds, causing the steel structure to deflect in appearance. The specific material quality of the steel structure has a great relationship with this phenomenon.

Wave deformation.

If the steel structure needs to be welded, its thickness is relatively small, and it is a thin plate structure. After high temperature, expansion will occur. After the weld is pulled by internal stress, shrinkage, and deformation will happen because this deformation appears. The resulting shape is wavy, so it is called wave deformation.

Spiral deformation.

After the welding, the steel component undergoes distortion and deformation, which is spiral deformation. This phenomenon is because the weld angles are not evenly distributed, and there are misaligned edges in the longitudinal position.

Horizontal and longitudinal deformation.

After the steel structure is welded, if the shrinkage deformation of the steel structure happens to be in the relevant axial position of the welding seam, it is longitudinal deformation. If the shrinkage deformation occurs in the vertical direction of the weld seam, it is a transverse deformation.

The reason for the steel structure welding deformation is that the relevant welds of the steel structure are affected by temperature and expand to varying degrees, resulting in horizontal and longitudinal deformation in the steel structure.

Factors affecting steel structure welding deformation:

Influence of welding method and process specification

The general welding methods in manufacturing steel structures include submerged arc automatic welding, manual arc welding, and CO2 gas-shielded welding. Different welding methods generate extra heat and cause various deformations. Steel structure welding caused by other welding process specifications is also further in the same welding method. Before the steel structure is welded, a welding procedure qualification guide must be formulated to guide welding. At the same time, there are requirements for the temperature and humidity of the working environment.

Influence of structural stiffness

Rigidity refers to the ability of a weldment to resist deformation, which is related to the weldment’s material, the weldment’s cross-sectional shape and size, etc. The greater the structural rigidity, the stronger the ability to prevent thermal deformation of the weld and its vicinity, and the smaller the welding deformation. On the contrary, the smaller the rigidity of the weldment, the greater the welding deformation. When the stiffness of the steel structure is minor, the welded seams are symmetrically distributed.

Only linear shortening deformation will occur when the welding procedures are correct and reasonable. When the welded seams are asymmetrically distributed, there is a distance between the weld shrinkage and the center of gravity. The upward bending of the section will produce bending deformation; when the welding procedure is reasonable, the center of the weld section and the center of the joint team are in the same direction, and only linear shortening will occur; when the center of the weld section deviates from the center of the common area, angular deformation will occur.

Influence of welding sequence

Different assembly and welding sequences will produce various deformations after welding, so a reasonable arrangement should be adopted during assembly and welding. Try to use symmetrical welding; when the weld is asymmetrical, weld the side with fewer welds first. Especially for welding components with many welds, reasonable selection of the welding sequence can effectively reduce welding deformation, and the deformations of multiple weldings can offset each other.

Control measures to reduce welding stress

1. Selection of weld size

Due to thermal expansion and contraction in the welding area, welding stress is formed. Generally, the more minor the welding area, the less heat input, the smaller the welding deformation, and the smaller the welding stress. For example, small-angle grooves and thick plates should use double-sided tracks to reduce welding stress.

2. Suitable welding materials and welding parameters

The selection of welding materials has an essential impact on the plasticity, toughness, and crack resistance of the weld metal and can also appropriately reduce the formation of hardened structures and stress concentration in the weld.

Typically, the carbon content of the base metal is higher than the carbon content of the weld metal. The strength of the weld to reach the same power as the base metal is mainly achieved by increasing the silicon and manganese content in the metal. The welding line energy in the welding parameters is proportional to the welding deformation; the more significant the welding line energy, the greater the welding plastic deformation produced, the greater the welding stress, and the greater the post-weld deformation, and vice versa.

3. Reasonable process

Long welds are inevitable in welded steel structures. In this case, segmented welding should be used instead of continuous welding.

Attention should be paid to segmental welding:

(1) Pay attention to the joints to stagger and cover each other’s joints to avoid joint alignment problems; (2) Pay attention to the welding deformation. When the temperature is too high, you need to stop, slowly cool, or turn the back of the welding;

(3) Pay attention to the order of welding multiple components. Generally, parts with more remarkable restraint are welded first, followed by members with less restriction.

4. Heat treatment measures

Appropriate heat treatment measures can eliminate stress and deformation on the one hand and prevent cracks on the other. For example, thick plates need to be preheated before cutting and welding. If the thickness of the low alloy steel plate exceeds 100 mm, the preheating temperature needs to be higher than 100 degrees Celsius, and the preheating range is 150mm to 200mm on both sides of the cutting line or groove. After welding, slow cooling or post-heat treatment is required to avoid hydrogen escape and accumulation, causing stress.

Analysis of control method for steel structure welding deformation

1. Analysis of steel structure welding deformation control in design

Due to its inherent properties, steel structures are not easy to repair after they are finished. If there are deficiencies and defects in the steel material during the design process, welding deformation will be inevitable. The errors at this time can only be repaired manually. The steel material can only be remanufactured if the design has severe flaws. Lack of innovation will lead to uncontrollable welding deformation of steel materials, while reasonable and scientific methods will significantly reduce the difficulty of welding and minimize the deformation during welding.

2. Analysis of steel structure welding deformation control during construction

In the construction and welding process of steel materials, different forms of welds and other structures of nodes are the basis for the welding construction of steel materials. Welds should be constructed using symmetrical welding methods. For asymmetrical welds, the side with fewer welds must be welded first, and then the construction on the other side is carried out. The deformation angle produced after welding can be reasonably controlled through the anti-deformation method before welding. When the thickness of the T-shaped joint plate is relatively large, we usually use the bevel angle for weld butt jointing.

3. Heat treatment measures

The heat treatment process is essential in the welding process of steel materials. When steel materials are directly exposed to high temperatures, reasonable heat treatment measures can eliminate deformation and stress and prevent cracks during deformation. The commonly used method is preheating and thick plate blanking during welding. Preheating steel materials during welding will effectively reduce the conventional cooling rate of the heat-affected zone and weld metal, inhibiting martensite formation in the hardened structure, thereby reducing the considerable stress generated by the weld and avoiding gas-cutting edges. Heat treatment measures are one of the essential methods to control the welding deformation of steel structures.

Conclusion

We can find many factors affecting welding deformation through relevant research on the control and correction of welding deformation of steel structures. Appropriate personnel should proceed from the objective reality of steel structures, thoroughly combine welding construction methods and research, and formulate the most optimized Reasonable welding deformation control and correction scheme.