In the construction of modern storage facilities, steel structure warehouses have become one of the mainstream building forms due to…

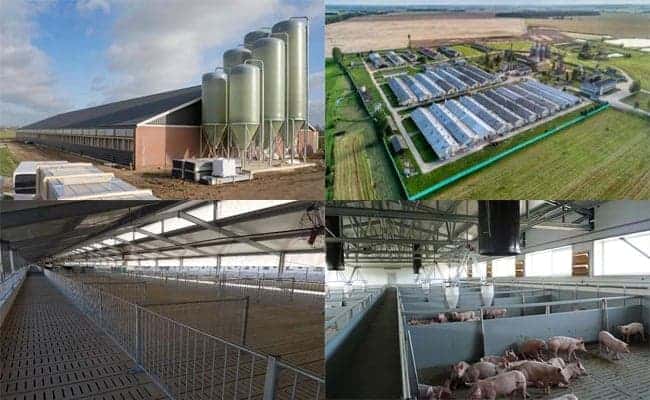

With the continuous development of modern agriculture, farmers have begun to pay more attention to animal welfare, environmental protection, and agricultural sustainability. In this context, the steel structure pig house, as an innovative design scheme, has gradually attracted people’s attention. The steel structure pig house design combines modern construction technology and agricultural needs to provide a sustainable and efficient environment for the farm, making pig breeding safer and more comfortable while reducing the adverse impact on the environment.

Structural design of steel structure pig house:

Truss structure:

Truss construction is built with triangular trusses, commonly found in long-span buildings, providing stability and strength. In a steel structure pig house, the truss structure can provide ample space for pigs while reducing the number of internal support columns. This type of structure is suitable for farms that need to provide a large area of activity space, such as free-range farming or large-scale farming.

Portal frame structure:

A portal structure is open, usually with two side supports and a roof. This structure is standard in steel structure pig house and suitable for occasions requiring a spacious interior space. The portal structure provides ample pig activity area and facilitates ventilation and environmental circulation. It is ideal for farms of all sizes, from small to large.

Material selection

The unique growth environment of the pig house makes the material should have good anti-corrosion performance.

The use of hot-dip galvanized steel structure components can improve the corrosion resistance of the primary and secondary structures of the truss, and the use of galvanized sheets and galvalume-coated sheets can improve the acid and alkali resistance of the enclosure system, such as roofs and suspended ceilings.

The basic structure of the pig house

A complete row of pig houses mainly comprises walls, roofs, floors, doors, windows, ditches, partitions, and other parts.

1) Wall: It is required to be strong, durable, and have good thermal insulation.

2) Roof: The insulation effect suits a corrugated steel roof sheet with glass fiber insulation cotton or sandwich panel.

3) Ground: The floor is required to be firm, durable, and seep well.

4) Feces and urine ditch: The open pig house must be located outside the front wall; the fully enclosed and semi-closed pig house can be found 40 cm away from the south wall, and a slatted floor is added. The width of the excrement and urine ditch should be designed according to the area inside the house, at least 30 cm wide. The gap width of the slatted floor shall not be greater than 1.5 cm.

5) Doors and windows: There should be a door on the front wall of the sports field in the open pig house, with a height of 0.8-1.0 meters and a width of 0.6 meters, 0.6 meters wide; the fully enclosed pig house only has a door on the side of the feeding passage, and the door is 0.8-1.0 meters high and 0.6 meters wide.

The entrance of the course is 1.8 meters high and 1.0 meters wide—no matter what kind of pig house should have a rear window. The length and height of the back window of the open and semi-enclosed pig houses are both 40 cm, and the distance between the upper frame and the top of the wall is 40 cm; It should be 1.1 meters; the windows on the back wall of the fully enclosed pig house can be large or small, and double glazing can be installed if conditions permit.

6) Pig pens: In addition to the pig houses with pens, partition pens are required in general closed pig houses. There are two kinds of fence materials, brick wall cement plaster and steel fence. The longitudinal bar should be fixed, and the horizontal fence can be a movable fence to adjust the area of the house.

Installation of steel structure pig house:

1. Main structure installation:

After checking the axis and elevation, install the steel columns and roof truss in sequence, and correct the verticality of the steel columns.

Precautions:

1) Check the verticality of the steel column with a plumb weight;

2) Pay attention to the direction of the bolt holes on the top of the column when installing the steel column;

3) The roof steel girder or truss beam at the gable wall must be temporarily pulled and positioned on both sides during installation to ensure that the curvature is within the quality control range, and it can only be released after the purlins are installed.

2. Secondary structure installation

Install roof and ceiling purlins, horizontal supports, and other secondary components.

Precautions:

1) First, the roof and then the ceiling;

2) Pay attention to the installation direction of the purlins at the eaves;

3) When installing the purlins for hanging the material line, it must be installed strictly according to the arrangement position of the material line in advance;

4) When installing the small window purlins on the ceiling, attention must be paid to the clearance size to meet the equipment installation requirements.

3. Roof panel installation

Process: laying steel wire mesh – laying insulation cotton – laying roof panels – installing edge trimmings

Precautions:

1) There should be no gaps at the joints of insulation cotton;

2) During roof panel construction, avoid stepping on parts without purlins;

3) The ridged plug should be installed and fitted, and the waterproof butyl tape should be laid.

4. Ceiling installation

Process: laying the air barrier film – installing the ceiling board – opening a hole in the small window of the ceiling – laying the insulation cotton – installing the edge fittings

Precautions:

1) The air barrier membrane should be installed smoothly, and the lap joints should be tight;

2) The nailing position and the plate overlap should be kept on the same straight line;

3) The thermal insulation cotton should be overlapped with upper and lower staggered seams.

5. Wall panel installation

Process: laying air barrier film, insulation cotton, installing inner and outer wall panels, and installing edge trimmings.

Pig house classification

Open pig house.

Backward to the sun, with walls on three sides, one side is open or semi-open, and a sports field is permanently set up on the concave side, and feeding, drinking, and excretion can also be done in the sports field. The house is only used for lying down and resting. To keep warm in winter, temporary wind-shielding facilities can be added.

Pig house with window.

Consider summer ventilation and organize ventilation routes. In order not to allow direct sunlight to enter the house in summer, while the sun shines on the pig bed in winter, the height of the upper opening of the window and the eaves should be reasonably designed. The pig house that relies on natural ventilation is about 10 meters wide. If the pig house is too narrow, it will increase the floor area and the area of the enclosure structure, and if it is too broad, it will affect the ventilation in the house.

Closed the pig house.

Generally, the windows are not opened, and the conditions such as light, temperature, humidity, and ventilation in the house are controlled by instruments and equipment. To prevent the impact of unexpected power outages, emergency windows can be set up. Its roof and walls have thermal insulation properties.

Types of pig houses

The design and construction of pig houses must first conform to the pig production process and consider their actual conditions.

(1) Boar house

The boat house is generally a single-row semi-open type. The temperature in the house is required to be 15-20 degrees, and the wind speed is 0.2 m/s.

(2) Houses for empty pregnant and pregnant sows

One of the most commonly used feeding methods for empty and pregnant sows is group feeding in large pens. Generally, 4 to 5 barren pregnant sows and 2 to 4 pregnant sows are raised in each cell. There are three types of pen structures: solid type, fence type, and comprehensive type. The pigsty layout is mostly single-aisle double-row type. The area of the sty is generally 7-9 square meters, the slope of the ground should not be greater than 1/45, and the surface should not be too smooth to prevent the sow from falling. Raising in single laps with one head per lap is also helpful. Sherwin requires 15 to 20 degrees and a wind speed of 0.2 m/s.

(3) Birthing Nursing House

The pig farm has farrowing pens, primarily arranged in two or three rows. The temperature in the house is required to be 15-20, and the wind speed is 0.2 m/s. The farrowing pen structure also varies according to conditions.

Ground farrowing crate: a single box is used, the middle part is the limit frame for sows, and the two sides are places for piglets to eat, drink, warm, and do other activities. The front of the sow limit frame is the front door, with troughs and drinking fountains for the sows to eat and drink. A slatted floor can be provided at the back of the pen to remove feces and dirt. Online farrowing cells: mainly composed of farrowing enclosures, piglet fences, slatted floor nets woven with steel bars, incubators, outriggers, etc.

(4) Piglet nursery

The temperature in the house is required to be 26-30 degrees, and the wind speed is 0.2 m/s. Online nursery pens can be used, 1 to 2 litters are raised online, and automatic feeding troughs are used to feed freely. Online breeding reduces the incidence of piglet diseases.

Pig farm equipment

It is an important measure to improve production levels and economic benefit to choose advanced and economical equipment compatible with the scale and technology of pig farms.

Pig Pens

(1) Boar pens, empty sow pens, and breeding pens

These types of pens are generally located in the same house, so the area is usually equal, the height of the pen is typically 1.2-1.4 meters, and the site is 7-9 square meters.

(2) Pregnancy pens

There are two types of gestation pens: one is a single pen, and the other is a small group pen. Metal materials weld the single column, generally 2 meters long, 0.65 meters wide, and 1 meter high. The structure of small group pens can be a concrete solid structure, fence type, or comprehensive structure. The difference is that the height of pregnancy pens is generally 1-1.2 meters. Due to restricted feeding, ground feeding is used instead of feeding troughs. The area is generally 7 to 15 square meters depending on the number of heads in each pen.

(3) The farrowing pen

The size of the farrowing pen is related to the selected sow breed. The length is generally 2 to 2.2 meters, and the width is 1.7 to 2.0 meters; the width of the sow limit pen is generally 0.6 to 0.65 meters, and the height is 1.0 meters. The width of each side of the piglet movable fence is generally 0.6-0.7 meters, the size is about 0.5 meters, and the distance between the walls is 5 cm.

(4) Piglet breeding pen

Generally, a metal woven mesh floor or plastic-plated floor is used, and the rearing effect of the latter is usually better than that of the former. Large and medium-sized pig farms mostly use high-bed net cultivation pens comprising metal woven manure leakage floors, fences, and automatic troughs. The leakage floor is set on the manure ditch or solid concrete ground through brackets and shared by two adjacent pens. One automatic drain and one automatic waterer for each column. This kind of nursery pen can keep the bed surface dry and clean and reduce the incidence of piglets. It is an ideal nursery pen. The height of the piglet nursery pen is generally 0.6 meters, and the distance between the fences is 5 to 8 cm. The area varies with the number of breeding heads.

(5) Breeding and fattening pens

There are many forms of growing and fattening pens. The floors are primarily concrete solid ground or cement slatted floor strips, and 1/3 slatted floor strips are also used, and 2/3 concrete solid ground is used. Concrete solid base ~ generally has a slope of 3%. The height of the fattening fence is typically 1 to 1.2 meters. The fence spacing is 8 to 10 cm when the fence structure is adopted.

Drinking water equipment

There are many automatic drinking fountains for pigs, such as duckbill type, cup type, and nipple type. Because the structure and performance of nipple and cup automatic drinking fountains are not as good as duckbill drinking fountains, duckbill automatic drinking fountains are generally used at present. See the structure of the duckbill-type pig automatic drinking fountain. It mainly comprises a valve body, valve core, sealing ring, return spring, plug, and filter net.

Feeding equipment

(1) Feeding trough at intervals

It is used in general pig farms with poor conditions. It is divided into fixed feeding troughs and mobile feeding troughs. Usually, cement pouring fixed feeding trough. In the picture, the feeding troughs of A and B are the same, all under the partition wall or fence. The feed is added from the corridor and slides to the inside, which is convenient for pigs to eat. The feeding trough is generally long, and the length of the feeding trough occupied by each pig should be determined according to the type and age of the pig. More standardized pig farms do not use mobile feeding troughs. Intensive and industrialized pig farms, pregnant sows, or lactating sows are reared in limited space; the fixed feeding trough is made of metal products, set on the limited space, see the part of the narrow farrowing bed and limited space.

(2) Square automatic feeding trough

Pig farms with general conditions do not use this feeding trough, which is common in intensive and factory farms. There are two types of square feeding troughs: single-opening and double opening. The single-open side is fixed on the partition or partition wall of the corridor; the double-open type is placed on the section or partition wall of the two columns. The automatic feeding trough is generally made of galvanized iron sheets and reinforced with steel bars. Very fragile.

(3) Round automatic feeding trough

The round automatic feeding trough is made of stainless steel, which is more durable. The chassis can also be poured with cast iron or cement. It is suitable for high-density, large-group growth, and fattening pig houses.

Advantages of steel structure pig house

The steel structure design can realize a large-span internal space and reduce the number of interior support columns. This gives the pigs more room to move around and helps with their natural behaviors, such as running, moving, etc.

The steel structure can provide a large span, thereby reducing the construction cost, and the saved budget can be used to improve the processing technology and the quality of the raw materials of the single product; A large number of corrosive gases such as ammonia and hydrogen sulfide generated inside the house will cause significant damage to the infrastructure in the high-temperature and high-humidity production environment.

The light steel keel of the steel structure farm adopts the factory prefabricated production mode in the processing link; that is, all the materials used in the engineering construction are directly transported from the factory to the construction site for assembly, reducing the intermediate links, which can shorten the construction time to the greatest extent—and control project duration. The excellent sealing ability of the steel pig house ensures the airtightness of the pig house. It uses the lower chord of the truss of the light steel structure as a strong support point for the ceiling of the pig house, which makes the airtight effect significantly better than other steel structures.