A steel portal frame structure is a type of low-rise building composed of steel columns and rafters joined by rigid…

A steel structure gymnasium is a gymnasium built mainly with steel. Its scale is designed according to the general gymnasium. The large steel structure gymnasium that can accommodate more than 10,000 people, and there are also small steel structure gymnasiums that can accommodate about 3,000 people. They are generally built according to their uses and design.

Steel Structure Gymnasium

The appearance and design style of the steel structure gymnasium are pretty different from the traditional construction model. The steel structure gymnasium first designs all the renderings, then processes and produces the spare parts according to the renderings, conducts trial installation, and finally installs the construction.

Traditional buildings are constructed directly according to fixed construction plans without the need for complicated renderings. According to the completion period, the steel structure gymnasium takes four months from design to completion. Still, the traditional construction method requires at least a construction period of more than one year in the same form. The steel structure is far better than Traditional construction from this point alone.

The Design of Steel Structure Gymnasium

The modern steel gymnasium’s architectural structure must satisfy aesthetics and practicality and consider safety, stability, and sustainability. In this case, steel structures have become one of the most commonly used structural types in stadium construction.

The advantages of steel structures are their lightweight, high strength, durability, and fast construction. The design of the steel structure stadium needs to consider many aspects, such as the building’s purpose, site, environment, and architectural requirements, to ensure the stability and safety of its structure.

In the design of the steel structure gymnasium, various mechanical calculations and simulations need to be performed to determine parameters such as the building’s load-bearing capacity and wind load to provide accurate data for the structural design of the building. Engineers also need to consider the fabrication and erection of steel structures to ensure the accuracy and reliability of the system.

Introduction to the Structure of Steel Structure Gymnasium

The steel structure gymnasium is a frame structure composed of steel and connectors. Its main components include columns, beams, frames, roofs, and exterior walls. The design and manufacture of steel structures require a high level of technology and precise processing to ensure the stability and safety of the system.

The fabrication and installation of a steel structure stadium require compliance with strict standards and specifications to ensure the accuracy and reliability of the system. Steel structure manufacturers need to use high-quality materials and modern manufacturing processes to ensure the quality and reliability of the structure.

World-famous Steel Structure Stadium Buildings:

Matmut Atlantique Stadium

Design: Herzog & de Meuron Location: Bordeaux, France

The project is in an open, flat site next to the Bordeaux Exhibition Center. With a capacity of up to 42,000 people, the stadium offers optimal views for all and maximum flexibility in terms of use, hosting not only rugby and football matches but also shows, concerts, and corporate events.

The new Bordeaux stadium appears light and open. Unity and homogeneity in scale, materiality, precision, and purity in form inspire a sense of monumentality and elegance. One might compare it to a classical temple. The stadium’s grand staircase blurs the boundaries between inside and outside, with numerous columns standing on the steps, blending and creating an open and accessible gesture.

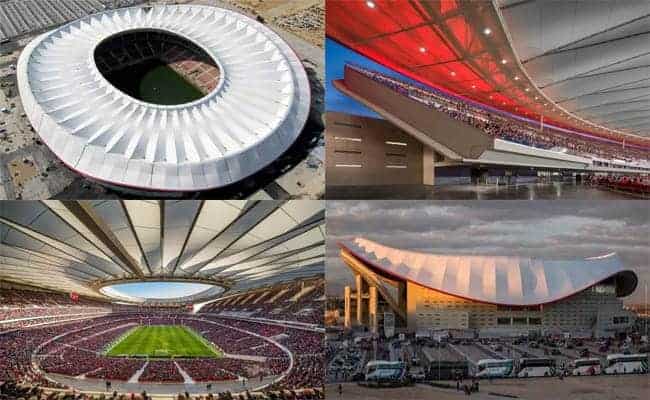

Wanda Metropolitan Football Stadium

Design: Cruz y Ortiz Architects

Location: Madrid, Spain

Atletico Madrid’s new stadium – the Wanda Metropolitano – is based on the renovation and expansion of the stadium built in 1994 by Cruz y Ortiz Architects. The new stadium can accommodate about 70,000 spectators, and its specifications will meet the highest standards of events such as the UEFA Champions League (UEFA Champions League) finals.

The stadium’s expansion achieved a dual goal: on the one hand, the recognizable elements of the old stadium were retained and continued. On the other hand, the extension nicely integrates the old stadium into a harmonious whole. The architects did not want the final product to be a combination of two different works but a single work that would represent the new image of Atlético Madrid with the perfect fit of the old and new parts.

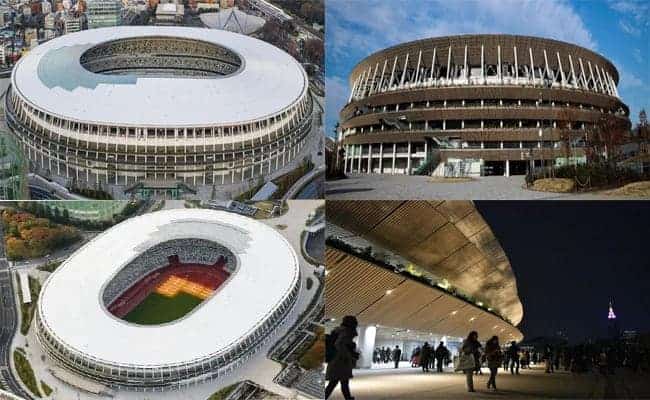

Japan National Stadium

Design: Kengo Kuma Architectural Urban Design Office Location: Tokyo, Japan

Japan National Stadium, designed by Kengo Kuma Architects in collaboration with Azusa Sekkei Corporation, has been completed and was initially planned to host the 2020 Tokyo Olympics and Paralympics. The construction work took about three years. Zaha Hadid once provided a proposal for this project, but it was not adopted because the budget was too high and could not be completed before 2020.

Wooden elements are used around the edges and roof of the building to demonstrate the connection with nature in a Japanese style. Many trees, flowers, and shrubs are planted to integrate the building with the environment better.

Pancho Arena

Design: Tamás Dobrosi + Doparum Architects

Location: Felciut, Hungary

The stadium covers an area of 12,000 square meters. Except for the northern and southern regions, where the stands protrude over the pitch, the other functional spaces are built inside the building. The relatively narrow space is further divided into smaller rooms by roof structural members that extend underground.

Timber roofs grow from reinforced concrete columns and spread out in the air like a tree’s canopy. The basic concept was to create a unique structure with its internal logic and clean static system that combines the rational tendencies of contemporary Hungarian stadium architecture with more complex forms and facilities in an innovative context.

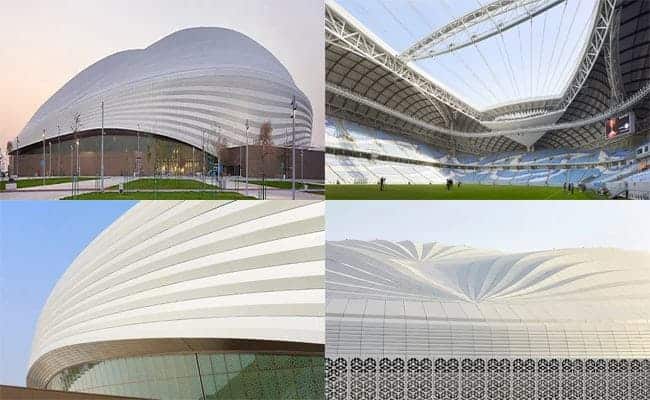

Al Janoub Stadium

Design: Zaha Hadid Architects

Location: Al Wakrah, Qatar

The project is to build a stadium with 40,000 fans for the 2022 World Cup in Qatar. The building is located in the coastal city of Wakla. The architect integrated the local traditional dhow into the design abstractly and made it meet the climate, environmental, and functional requirements.

The stadium’s roof and shell design is based on the dhow, reflected in its geometry, materials, and details. The metal strips above the eaves also echo the wooden components of the dhow. The stadium’s opaque roof and pleated side walls are inspired by Arabic patterns, enhancing the texture of the shell and emphasizing the stadium’s unique geometry.

Estádio Mineirão

Design: GMP, SBP,

Location: Belvedere City, Brazil

The Mineiro Stadium was built between 1963 and 1965, designed by Eduardo Méndez Guimarães II and Caspar Garreto. Its expressive concrete structure makes it a protected heritage building. The renovation plan aims to match the historic building with a modern stadium’s functional, technical, and infrastructural requirements. The renovation includes a lightweight grandstand roof that complements the retained concrete roof to safeguard all seats from wind, rain, and sun.

National Stadium

Design: GMP, SBP,

Location: Brasilia, Brazil

The National Stadium of Brazil was built on the original Mané Garrincha Stadium site. This circular gallery has a dense forest-like colonnade structure and a double-layer suspended ceiling. The design aimed to find a suitable architectural solution for the plot that would inherit the traditional character of the place while also being an excellent modern building.

As the most prominent building on Brasília Avenue, the city’s central axis, the stadium develops into a solid structural volume consistent with its urban context. Colonnades surround the bowl-shaped stadium. The dense forest-like arcades support the roof and accommodate all the circulation lines in the stadium. This apparent gesture is emphasized by components reduced almost to the point of prototype, with concrete as the primary material. The circular suspended roof is a double-layered structure with an upper layer of fiberglass cloth coated with a non-stick coating and a lower membrane of backlit mesh fabric.

Optus Stadium

Design: HASSELL, Cox, HKS

Location: Perth, Australia

The stadium can host any type of event – including Australian rules football, cricket, rugby, and soccer- concerts and other large-scale cultural and entertainment events. It can accommodate 60,000 people in rugby mode, 65,000 in rectangular mode, and 70,000 in concert mode.

The striking sunlit bronze façade (coated in anodized aluminum) showcases Western Australia’s unique geological features. When night falls, the LED lighting system can change into the colors of the host team. The lightweight fabric stadium roof covers 85% of the seats to cope with the hot and sunny local climate. Viewers can see across the Swan River to the city center. The surrounding landscape design highlights the Aboriginal history and culture of the area.

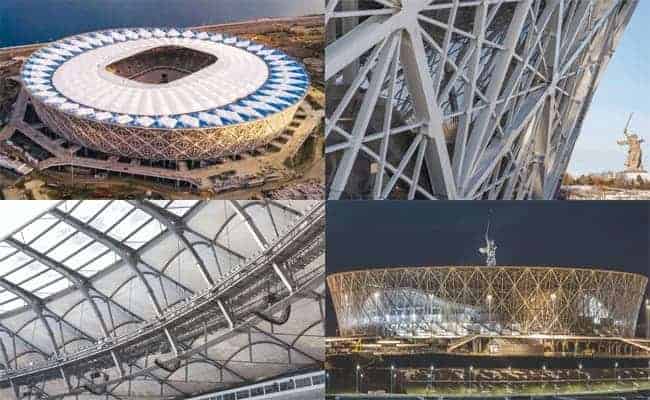

Volgograd-Arena Football Stadium

Design: PI ARENA

Location: Volgograd, Russia

The stadium is designed to integrate with the historical and cultural fabric. The orientation of the stadium must strictly adhere to the north-south direction, so the architect did not create it on the original urban axis. Still, its structure can echo the cultural history of the city.

The design adopts an inverted truncated cone, and the facade is a stainless steel grid structure. Viewed from the front, the building presents a solemn image, symbolizing military honor and paying tribute to those dedicated to defending the country.

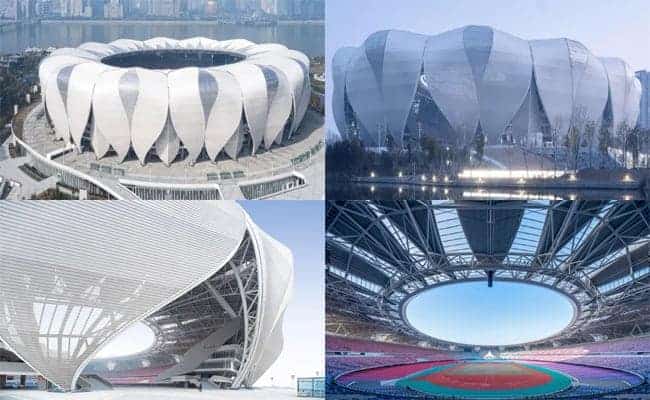

Main Stadium of Hangzhou Olympic Sports Center

Design: NBBJ + CCDI

Location: Hangzhou, China

The stadium design is inspired by the lotus flowers on the West Lake, with petal-like cladding surrounding the 80,000-seat stadium. “The stadium utilizes West Lake’s native water lilies as its conceptual inspiration, interpreting the form as a series of modular petal structures that elegantly wrap around the stadium.

The building is constructed primarily of steel structure, with a parametric facade and roof structure design. This ensures the building is as light as possible, reducing material waste and the building’s carbon footprint.

Characteristics of Steel Structure Gymnasium

- The single-layer span is large; multi-layer steel structures can also be used for construction.

- Simple construction; short construction period: All components are prefabricated in the factory and only need to be assembled on-site, thus significantly shortening the construction period. A 6,000-square-meter building can be installed in just 40 days.

- Durable; steel structure gymnasium is easy to maintain: Steel structure buildings designed by general computers can resist harsh weather and require simple maintenance.

- Beautiful and practical, the steel structure building has simple, smooth lines and a modern feel. Colored wall panels are available in various colors, and the walls can also be made of other materials, giving you more flexibility.

- Reasonable cost: The steel structure gymnasium building is light in weight, reduces the essential price, and is more than half the cost of traditional concrete buildings. The construction speed is fast, and the comprehensive economic benefits are much better than concrete buildings.