In the construction of modern storage facilities, steel structure warehouses have become one of the mainstream building forms due to…

What are steel structure fabrication drawings?

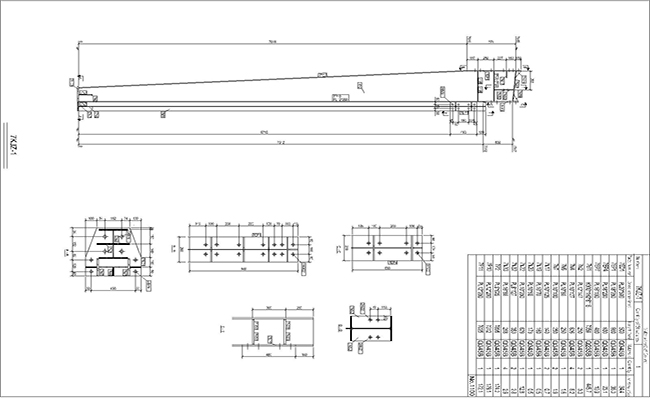

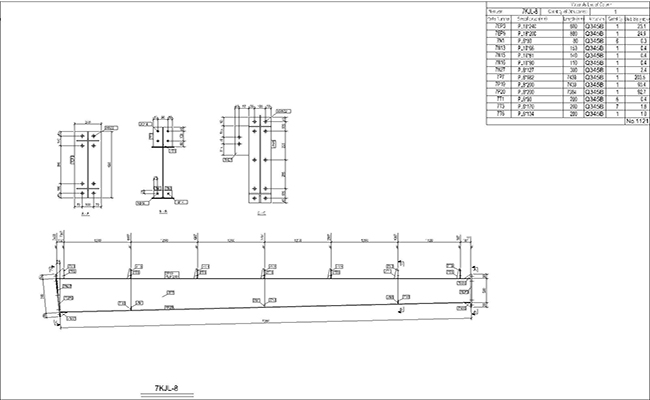

Steel structure fabrication drawings, also known as processing details, refer to technical documents that use drawings to accurately express the geometric shape of steel structure components, the specifications, and dimensions of primary and secondary parts, the relative positions between parts, welding forms, and technical requirements in steel building projects.

The initial design of a steel structure building generally refers to a scheme drawing or sketch, sometimes provided directly by the owner or with essential information. The steel structure company offers a design scheme drawing or sketch. The scheme drawing of a steel structure building only provides essential structural references and is unsuitable for processing and production.

After the customer confirms the scheme drawing, the steel structure processing drawing will be carried out.

Steel structure fabrication drawings should include auxiliary materials such as in-depth design instructions, drawing catalogs, and component material report lists.

The main contents of steel structure fabrication drawings are:

- Filing classification numbering of the whole set of drawings, numbering principles of components and parts, material requirements, special processing and quality requirements, basic principles of construction layout, anti-corrosion and fire prevention requirements, storage and transportation conditions, etc.

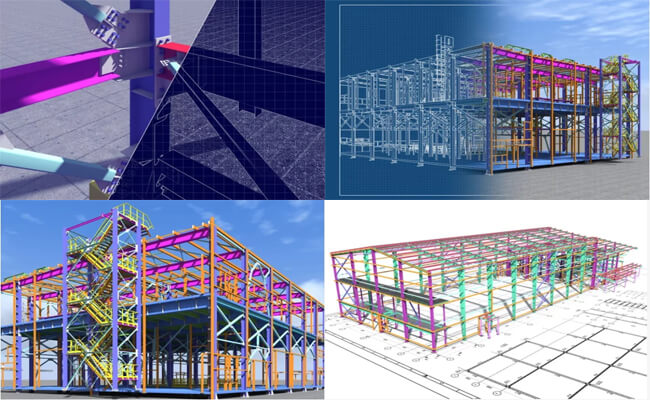

- Construction and installation drawings: the position and installation method of each component in the entire building, generally including plan and elevation drawings, which are mainly used to guide the installation and construction of the construction site and are also a layout check for whether the installation of each component collides. It can also be used by architectural design and structural design engineers to check and review detailed design drawings.

- Component processing details include processing components’ cutting, drilling, planning, welding and component processing, surface treatment, etc. These details are mainly used to guide factory manufacturing and processing drawings and documents (steel structure details in a narrow sense, that is, processing details).

- Material list: This provides the basis for material procurement and budgeting, progress control, and processing management. This type of information is indispensable for processing management. Processing units can carry out management tasks, such as processing organization planning, cost control, and progress management.

- Welding standards and node details after deepening: Based on the data results of structural design, under the guidance of industry and national norms, considering the actual situation of the technical equipment of the processing and manufacturing unit, it is provided to the designer for inspection and review, and provides the basis for processing operations to the processing manufacturer.

Steel structure deepening design

Steel structure fabrication drawings are design deepening, which means deepening the design to make the drawings more comprehensive.

The connection points meet the design and installation requirements to implement the project smoothly. The detailed design includes all its contents and the material supply, transportation, installation methods, and sequence required by the construction party. After the detailed design is confirmed, it can be directly disassembled for processing needs.

Deepening design is necessary to solve the problems and defects in the preliminary design. If the initial design is imperfect, the construction will have many issues, such as unreasonable component connections, inaccurate node design, and complex construction.

Steel structure fabrication drawings can refine and improve the preliminary design, ensuring smooth construction progress and the structure’s safety and reliability.

Secondly, in-depth design helps improve steel structures’ performance and economic benefits. Through in-depth design, steel structures can be optimized to improve their stress performance, stability, seismic resistance, etc.

In addition, in-depth design can fully consider various factors in the construction process and improve construction efficiency and quality. Finally, in-depth design is also an essential means of meeting the needs of owners and design units.

The in-depth design of steel structures is based on many considerations and needs. It can solve the problems and defects in the preliminary design and improve the structure’s performance and economic benefits. It can also fully consider various factors in the construction process and improve construction efficiency and quality.

At the same time, in-depth design can also meet the needs of owners and design units and promote the smooth implementation and completion of the project. Therefore, in-depth design is an indispensable link in steel structure projects, which is significant to ensuring the structure’s safety, stability, and economic benefits.