As the primary building material for steel structure industrial buildings, light steel structures directly affect the stability of the main…

The steel structure crane beam, as the name implies, is the beam structure used to support the operation of the crane. To meet various production needs in industrial plants, it is generally necessary to add cranes. For this reason, crane beams are considered in the design of steel workshop buildings with cranes.

The Crane girder system is composed of a crane beam (also can be a crane truss), brake structure (brake plate, brake truss), auxiliary truss and bracing (horizontal and vertical bracing), etc. Indeed, when the span of the crane girder and the load of the crane carried are small, the braking structure can also be canceled. The following pictures will give you an intuitive feeling:

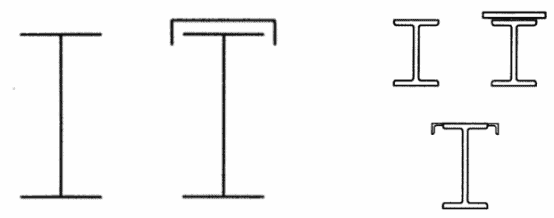

The form of the steel structure crane beam:

It is generally simple in structure and convenient in construction. Standard crane girders include section steel, composite H-shaped, box girders, wall-traveling crane girders, etc. The most commonly used crane girders are H-shaped steel girders.

1. Section steel beams

Section steel crane beams are directly made of hot-rolled H-shaped steel, which is easy to manufacture, but the steel consumption is slightly higher. It is generally applicable to the situation where the span of the beam is L≤9m and the crane’s lifting capacity is Q≤20t.

2. Welded H-shaped steel

Welded H-shaped beam has good bearing performance, reliable operation, simple construction, and easy optimization of beam section, which is the most commonly used type.

3. Box-shape beam

The box-shaped crane beam has the advantages of high stiffness and good anti-torsion performance, making it suitable for large-span, large-tonnage soft-hook cranes or hard-hook cranes with an A8 working level. It is also ideal for crane beams with high requirements for anti-torsion stiffness, such as large-span wall traveling crane beams. However, the manufacturing process is complex, and the welding operation conditions are poor, making it difficult to control and correct welding deformation.

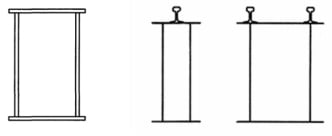

Wall traveling beam:

The wall-traveling crane beam consists of two separate beams: an upper beam with horizontal loads and a lower beam with horizontal and vertical loads. The separated form is more economical, but strict control must be exercised over the relative deformation between the upper and lower beams. To increase the stiffness of the crane structure, the upper and lower beams can also be combined into a box-shaped cross-section.

The load of the steel structure crane beam

The crane beam is subjected to three types of loads: vertical loads (system weight and the weight of the load being lifted), horizontal loads (braking force and rail clamp force), and longitudinal horizontal loads (braking power). The crane beam is designed to withstand bi-directional bending and does not consider longitudinal horizontal loads. The vertical load is permanent, while the horizontal load is a dynamic load that can cause fatigue damage due to its repetitive action. Therefore, high-quality steel is required to meet conventional requirements such as tensile strength, elongation, and yield point and ensure that impact toughness is qualified.

Although the calculation model for the crane beam and braking structure is relatively simple, their importance to production and construction and the potential for small details to be overlooked in design and calculation can lead to irrational design. Therefore, it is essential to have a detailed understanding and emphasis on crane beams. The most crucial step is to choose a professional and experienced design or steel structure company, which can significantly reduce the risk of design or production errors.

Steel Grade for Crane Beam

When selecting steel, Q355B steel is commonly used in large-span and heavy-duty factories, while Q235B steel is used in workshop buildings with small spans and lifting capacities. Therefore, it is essential to consider the rationality and economy of the section. The height of the crane beam section and the thickness of the upper and lower flanges and web plate is not fixed and must be determined through multiple calculations to find a safe and economic unit. It is easy to overlook the impact toughness of the steel when selecting it.