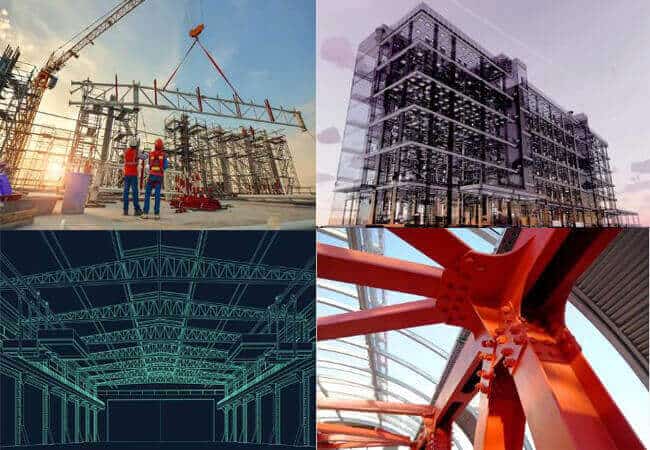

A steel frame is a structure made of steel, usually connected by welding, bolting, or riveting steel beams, columns, bracing,…

Steel structure occupies a crucial position in construction projects, and its stability and strength directly determine the overall quality of construction projects. Therefore, in the process of steel structure building design and engineering implementation, it is crucial to optimize the steel structure design, improve its strength, and then enhance stability and quality.

Key points of steel structure building design

The core component of steel structure building is steel, which has good uniformity and high strength. With the improvement of corrosion resistance, heat resistance and fire resistance of steel, the application scope of steel structure continues to expand. The key components in steel structure building design are usually connected by bolts. When designing, it is necessary to fully apply the principles of mechanics, scientifically handle the force arm and bending moment relationship of each component, and ensure the reasonable connection of each node.

Functional requirements: The primary task of steel structure building design is to meet the functional requirements of the building, including purpose, spatial layout, etc. Designers need to have a deep understanding of the functional requirements of the building to ensure that the steel structure can effectively support and meet the use requirements.

Building load: Steel structure buildings need to bear loads such as self-weight, personnel activities, rain, wind, vibration, etc. During the design process, the size and mode of action of various loads should be reasonably determined according to the actual situation to ensure that the steel structure can withstand the expected mechanical load.

Architectural form: In steel structure building design, it is essential to consider the appearance and form of the building. The steel structure has strong plasticity and can realize complex architectural forms. Designers can flexibly design according to actual needs.

Stability of steel structure building design: During the design process, attention should be paid to the stability of the structure, and the structural system should be reasonably selected to ensure the overall stability and compressive resistance. Through mechanical calculation and analysis, ensure that the strength and stability of the steel structure meet the design requirements.

Construction process: Consideration of construction technology is also an essential aspect of steel structure building design. The process requirements of steel structure manufacturing, transportation, installation, etc. need to be closely coordinated with the design to ensure the smooth progress of construction.

Environmental impact: Factors such as the geographical environment and climatic conditions of the building should be considered in steel structure building design, and measures should be taken to deal with the impact of natural disasters such as wind, rain, and earthquakes to ensure the safety and reliability of the building.

Economic and sustainability: When designing, it is necessary to comprehensively consider materials, construction costs, and use costs to ensure the economy of the building. At the same time, the design should take into account sustainability, such as the use of renewable materials, energy-saving design and low-carbon technology to reduce the negative impact on the environment.

Component and node design

Optimizing the cross-section of steel structure components is a key measure to reduce the cost of steel structures. Especially for complex steel structures, the cross-section and node design of each component must be strictly checked. This process requires strength design and force analysis, and ensures that the connection of the node meets the specifications. The installation work must also be strictly carried out following the requirements to ensure the safety of the structure.

Anti-corrosion design

Anti-corrosion is a key link in steel structure building design. The environment of the construction site should be considered during design, and effective anti-corrosion measures should be taken to extend the service life of the steel structure. Standard anti-corrosion measures include coating anti-corrosion materials or coatings to enhance the corrosion resistance of steel structures. According to the requirements of anti-corrosion, semi-permanent or permanent coatings can be selected.

Fire protection design points

Fire protection design occupies an essential position in steel structure buildings, and materials with high fire resistance must be selected. Construction projects should select appropriate fire protection materials according to fire protection levels and requirements. In addition, the stability of the structure should be ensured during design to avoid deformation, and the stability and continuity of the steel structure should be enhanced through design.

Challenges and solutions for steel structure building design

Issue 1: Structural design and stability maintenance

Challenge: The design and stability of steel structure buildings are the most basic and complex tasks. Steel structures usually involve large spans, high-rise, and even super-high-rise designs. Ensuring the stability of buildings under various environmental conditions is the key to the design. The mechanical properties of steel, the gravity distribution of buildings, and the lateral force resistance performance all require precise calculation and analysis. Any slight mistake may affect the overall safety of the building.

Solution: A reasonable selection of steel performance, especially for high-rise or super-high-rise buildings, and the use of high-strength steel is the core method to ensure the stability of the building. During the design process, steel structure building design needs to use advanced calculation and analysis tools to optimize the building structure and ensure stability under various external forces through experimental simulation and actual testing.

Case: CCTV Headquarters Building

The CCTV Headquarters Building has a unique shape, and the overall structure looks tilted, giving people an unstable impression. However, in the actual design, the core structure is vertical. The stability of the building is ensured by using high-strength steel and design methods such as steel trusses, external keels and diagonal tie rods. This design breaks through the traditional concept of steel structure building design and provides a feasible solution for the structural stability of super high-rise buildings.

Issue 2: Wind and earthquake resistance

Challenge: Steel structure buildings, especially high-rise buildings, are often susceptible to wind and earthquakes due to their light weight and flexible structure. Especially under extreme weather conditions, the wind and earthquake resistance of buildings become key. The design of steel structure buildings must consider how to reduce the impact of wind vibration and enhance earthquake resistance to ensure the safety of buildings in earthquakes or strong winds.

Solution: Using dampers is an effective way to solve the problem of wind resistance. Dampers are usually installed on the top of the building and can effectively reduce vibration caused by wind. At the same time, through wind tunnel testing, designers can accurately analyze the impact of wind loads on buildings and adjust the design based on data. In addition, advanced technologies and earthquake-proof measures in earthquake engineering such as seismic isolation devices and energy dissipation devices can also effectively improve the earthquake resistance of buildings.

Case: Guangzhou Tower

The Guangzhou Tower is a unique steel structure building with enormous design challenges, especially in terms of wind and earthquake resistance. The design of Guangzhou Tower not only subverts the traditional “thick on top and thin on bottom” design principle, but also adopts a number of innovative technologies, such as installing large dampers to reduce the impact of wind on the building, and conducting precise wind tunnel tests on the tower. The damper is also designed as a fire water tank at the top of the tower, which can take on the fire protection function while preventing wind.

Question 3: Environmental protection and sustainability

Challenge: The production process of steel structure buildings will produce certain pollution, and the discharge of waste gas, waste water, and waste residue will put pressure on the environment. As the world pays more and more attention to green buildings, how to achieve sustainable design in steel structure building design and reduce environmental impact has become an essential issue in the construction industry.

Solution: Improve steel production technology, promote the use of recycled steel and recyclable building materials, adopt environmentally friendly design solutions, improve the energy efficiency of buildings and reduce carbon footprint. Adopt green building technologies such as solar photovoltaic, power recovery, ground source heat pumps and other technologies to enhance the sustainability of buildings.

Case: Sustainable Energy Center of Nottingham University of Ningbo

The Sustainable Energy Center of Nottingham University of Ningbo adopts the concept of “increasing income and reducing expenditure” and combines low-carbon technology to achieve near-zero carbon emissions in building operation. The building’s facade adopts a double-layer curtain wall structure, which not only improves thermal insulation, but also effectively reduces indoor noise. In addition, the project also uses natural ventilation, solar photovoltaic and solar thermal technology, and uses a ground-source heat pump system to minimize energy consumption, promoting the environmental protection and sustainable development of the building.

Question 4: Maintenance and durability

Challenge: Due to the metallic properties of steel, steel-structured buildings are easily corroded by moisture, oxygen and pollutants in the air, causing corrosion and aging, which in turn affects their structural safety and appearance. How to extend the service life of the building and maintain its performance and beauty is another challenge facing steel-structured buildings.

Solution: Regular anti-corrosion treatment and maintenance, using corrosion-resistant steel or coatings to reduce the impact of the environment on the structure. In addition, regular inspection and maintenance are also key measures to ensure the long-term stability of the building.

Case: Eiffel Tower

As a world-famous steel structure building, the Eiffel Tower was originally designed to last for 25 years, but it has stood for more than 130 years. Through regular maintenance and repainting anti-corrosion paint every seven years, the tower has maintained a good structural condition. The Eiffel Tower demonstrates the successful experience of steel structure construction in terms of maintenance and durability, showing that proper care can significantly extend the service life of a building.

Conclusion

Steel structure building design and construction is full of challenges. Still, with the continuous advancement of technology and the introduction of innovative concepts, steel structures have become an essential trend in modern urban construction while meeting the requirements of safety, durability, and environmental protection. Through continuous technological innovation, steel structure buildings will continue to promote the sustainable development of the construction industry in the future.