The service life of steel structure buildings is more than 50 years. The roof and wall panels of prefabricated steel…

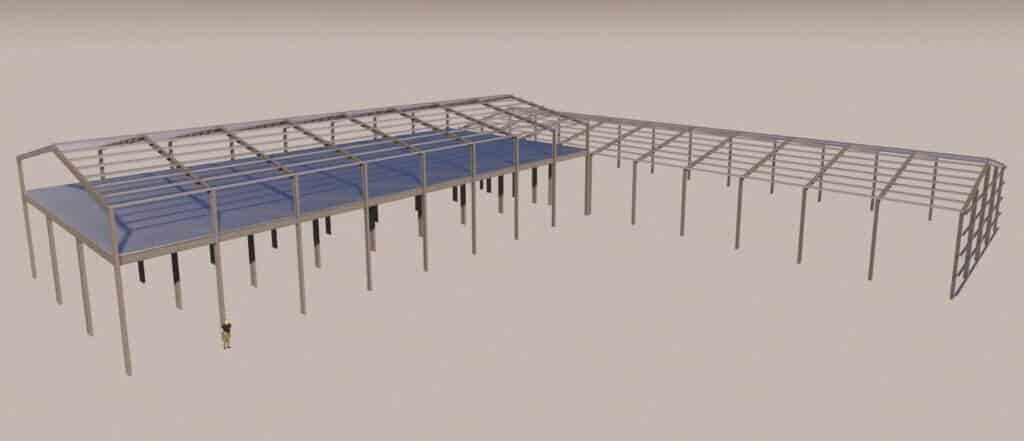

Havit Steel Structure designed an L-shaped steel storage building in Ghana used to store and turn goods. Ghana is located in western Africa, rich in gold, and its official language is English. The country has an area of 238,537 square kilometers and a total population of approximately 29.5 million.

Steel Storage Building in Ghana:

The L-shaped storage building is divided into two parts. One part is 50 meters long, and 9 meters high, double floor, and first floor is 6 meters high. The other part is 40 meters long and 20 meters wide, a single-story height of 6 meters. The wall made of concrete brick, and the roof is 0.5mm thick color steel plates.

Enclosure Structure of Steel Storage Building in Ghana:

The wall and roof system is the enclosure structure of the steel structure building, which mainly protects the equipment, and personnel inside of the building so that the steel storage building has good sound insulation and heat preservation effects.

The wall materials include the following two types:

1. Metal Cladding

It consists of a light-weight color steel sheet or sandwich panels. The core material of the color steel sandwich panels can be fiberglass wool and polyurethane or foam core materials. The metal cladding is fixed on the steel structure building by purlins or wall girt.

2. Concrete Wall

It is mainly filled with lightweight filling materials, such as hollow block aerated concrete blocks or new earth brick masonry. If concrete walls are used, wall girts are not required.

The structural form of steel storage building:

1. Brick-built

The structure is that the primary frame is made of steel rebar and concrete cast-in-place, and the wall part is made of civil fired bricks. The construction was completed by wet handwork on site. The primary method is not only low productivity, long construction period, high investment cost, but also pollution to the environment. The service life of this kind of factory is generally about 30 years, and it is not earthquake resistant. Once a massive earthquake occurs, it is easy to collapse, and now the world is advocating building energy efficiency. With the changes of the times, this structure will gradually fade out of the market.

2. Mixed Steel Structure Storage Building

The structure uses steel as the mainframe and brick wall as the enclosure system, which can meet the functions of large span, anti-corrosion, and fire protection, so the utilization rate is still very high. Still, the investment cost of this structure is high.

The building materials cannot be recycled after being demolished, which does not meet the needs of my country’s sustainable economic development.

3. Steel Structure Storage Building

All components of the steel storage building are made of the steel structure. From anchor bolts, steel columns, steel beams, roof purlin, wall girt, and bracing. They are all steel products. The walls and roofs are also made of metal cladding. These materials are not only lightweight, robust, and fast disassembly and assembly, short construction time, and recyclable. It is currently one of the most earthquake-resistant building types in the world.