In the construction of modern storage facilities, steel structure warehouses have become one of the mainstream building forms due to…

Prefabricated metal warehouse buildings are closed building system that uses metal structure as the main load-bearing system and is matched with roof and wall systems. Prefabricated warehouse structure can not only meet the customized needs of customers but also be completed faster.

Prefabricated warehouse buildings are widely used and their market share is increasing, mainly due to their advantages such as short construction period, relatively low cost, beautiful and durable. With the rapid development of the manufacturing industry, the demand for prefabricated warehouses is increasing compared to concrete structure warehouses.

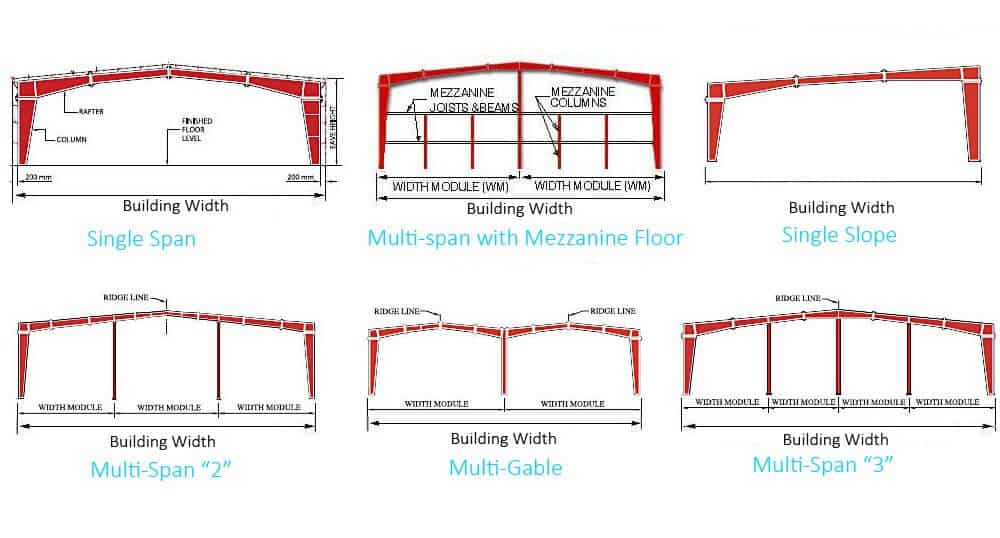

Structural scheme of prefabricated metal warehouse buildings:

Single-span warehouse:

As the name suggests, a single-span warehouse is a warehouse with only one span and no intermediate columns. The design of a single-span warehouse is relatively simple and easy to construct. It is suitable for small or medium-sized warehouses. The main advantage is high internal space utilization and large storage space, which is conducive to the placement and transportation of goods.

Structural features:

Span range: generally between 15 meters and 30 meters.

Height: usually between 6 meters and 9 meters.

Components: mainly include steel beams, steel columns, bracing systems, roofs and wall panels.

Advantages

Open interior space: no intermediate columns, convenient for placing and transporting goods.

Quick construction: simple structure, short construction period.

Convenient maintenance: no internal barriers, easy to clean and maintain.

Applicable scenarios:

Single-span steel structure warehouses are suitable for the storage needs of small and medium-sized enterprises, such as parts storage, general cargo storage, etc.

Multi-span warehouses:

Multi-span warehouses are warehouses with multiple spans separated by intermediate support columns. Multi-span warehouses are more suitable for large-area warehouses, and multi-span design can support larger roof structures.

Structural features:

Span range: each span is usually between 18 meters and 25 meters.

Height: usually between 6 meters and 11 meters.

Components: In addition to steel beams, columns, roofs and wall panels, it also includes intermediate support columns.

Advantages

Applicable to large-area buildings: Through multi-span design, a larger building area can be covered.

Flexible partitioning: The interior can be flexibly partitioned to adapt to different usage needs.

Stable structure: The intermediate support column increases the stability of the building.

Applicable scenarios:

Multi-span steel structure warehouses are suitable for large enterprises or scenarios that require large-scale storage, such as logistics centers, large storage centers, etc.

Large-span warehouses:

Large-span warehouses refer to warehouse buildings with particularly large spans, which are usually used for special storage needs, such as large equipment, aircraft, etc. The design of this type of warehouse is complex and has high requirements for materials and structures.

Structural features

Span range: generally more than 30 meters, even more than 50 meters.

Height: may reach more than 15 meters as needed.

Components: Use specially made large steel beams and steel columns, and use high-strength roofing and wall panel materials.

Advantages

Extra-large internal space: suitable for storing large equipment, machinery, etc.

No intermediate support columns: The internal space is completely open, which is convenient for operation and transportation.

High load-bearing capacity: High-strength steel is used, with strong load-bearing capacity.

Applicable scenarios:

Large-span steel structure warehouses are suitable for industries such as aviation, shipbuilding, and large-scale machinery manufacturing, where large equipment needs to be stored or large-scale operations need to be carried out.

Warehouse with mezzanine:

Warehouse with mezzanine adds one or more mezzanines to the original warehouse structure for storing more goods or office purposes. The design of the mezzanine needs to consider the bearing capacity and use function of the structure.

Structural features:

Number of floors: usually two or three floors.

Height: The height of each floor is usually between 3 meters and 5 meters.

Components: In addition to conventional steel beams and steel columns, it also includes mezzanine floors, stairs and guardrails.

Advantages

High space utilization: Increased vertical space usage.

Various functions: The mezzanine can be used for storage, office, rest area, etc.

Flexible structure: The mezzanine can be adjusted and modified according to needs.

Applicable scenarios

The steel structure warehouse with mezzanine is suitable for enterprises that need partitioned storage or office, such as small and medium-sized manufacturing enterprises, warehousing companies, etc.

Selection of roof and wall materials for prefabricated metal warehouse buildings:

Corrugated color-coated steel sheet

Corrugated color-coated steel sheet is a lightweight, high-strength roofing material commonly used in various warehouse buildings.

Advantages:

Convenient construction: fast installation and short construction period.

Beautiful: Various colors can be selected according to needs.

Durable: Good corrosion resistance.

Disadvantages:

Poor thermal insulation: In hot weather, the internal temperature is high.

Average sound insulation: Easily affected by external noise.

Sandwich Panel:

The sandwich panel consists of two layers of color steel sheet and the insulation material in the middle, with excellent thermal insulation performance.

Advantages

Thermal insulation: It can effectively adjust the temperature inside the warehouse.

Good sound insulation: The middle layer material can block noise.

Disadvantages

High cost: Compared with single-layer color steel plates, the cost is higher, the space occupied is large, and the transportation cost is also increased accordingly.

Increased weight: The bearing capacity of the structure is required to be higher.

Aluminum-magnesium-manganese alloy sheet:

Aluminum-magnesium-manganese alloy sheet is a new type of roofing material with the characteristics of light weight and high strength.

Advantages:

Light weight: Reduce the load on the building structure.

Corrosion resistance: Long service life and low maintenance cost.

Beautiful: It has a metallic luster and good decorative effect.

Disadvantages:

High cost: The material price is relatively expensive.

Complex construction: professional installation team is required.

Prefabricated metal warehouse buildings have a variety of structural types to choose from. Different types of warehouses have their own advantages and characteristics to meet different usage scenarios and needs.

For warehouses with smaller areas, it is recommended to choose single-span prefabricated warehouses with open internal space to increase storage space; for warehouses with larger scale and large area, it is recommended to choose multi-span warehouses, which are safe, durable and economical;

Special large equipment such as aircraft and ships can choose large-span warehouses, which can provide ultra-large unsupported internal space;

For multi-functional needs such as office, workshop, and warehousing, it is recommended to choose prefabricated metal warehouse buildings with mezzanines to increase the vertical use space; land resources are limited but storage needs are large, it is recommended to choose multi-layer prefabricated warehouses, and the construction cost of storage space of the same area is relatively low.

After understanding the several types of prefabricated metal warehouse buildings, when enterprises choose to build warehouses, they can choose a reasonable warehouse type according to their own needs and specific application scenarios to achieve the best use effect.