A steel frame is a structure made of steel, usually connected by welding, bolting, or riveting steel beams, columns, bracing,…

Prefab steel building structure is widely used in various construction structures. It is suitable for workshop structures with large spans, large loads or cranes, vibration or high temperature, and frames requiring movement or frequent assembly and disassembly and houses in earthquake-prone areas.

The forms of prefab steel building structure:

Large-span steel structure

Space structure functionally refers to a structural system that can form a larger continuous space, mainly including grids, reticulated shells, cable-membrane structures, and combined and hybrid structures. Its characteristics are sizeable continuous span, ample space, large area, light, beautiful, modern linear appearance, good seismic performance.

Large-span prefab steel building structure is mainly used in stadiums, conference halls, large shopping malls, exhibition halls, event centers, and other large public event buildings, hangars, workshops, decorative halls, etc.

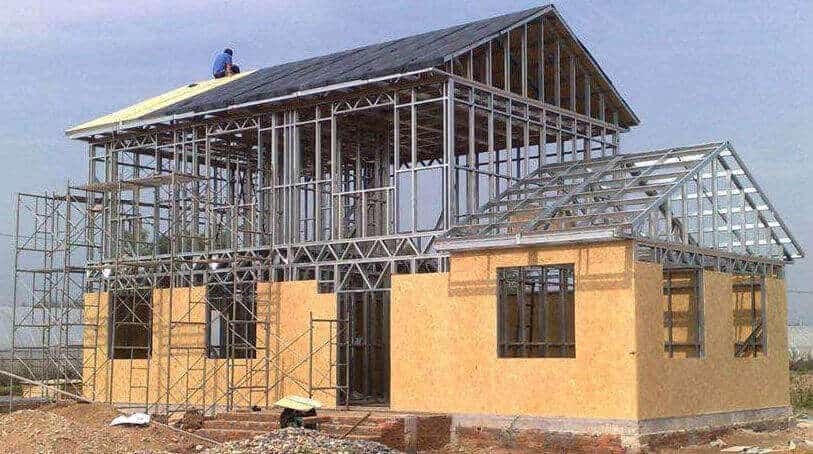

Light steel villa

Light steel villa, also known as light steel structure house, is a lightweight steel keel synthesized from hot-dip galvanized aluminum steel strip through cold rolling technology.

The steel wall structure system comprises light steel multi-ribbed beams and columns and the maintenance structure. It has excellent physical performance indicators, a short construction period, and a sound insulation effect.

All structural components are made of high-strength galvanized steel to ensure the service life of the house. All components are cold-formed by the factory’s precision machinery assembly line, and the dimensional accuracy is in millimeters, which is unmatched by other structures.

The prefab steel building structure is a residential structural system suitable for innovation. The steel structure can be designed with various shapes, sizes, and spaces of new houses following people’s different aesthetics and functional requirements. The manufacturer can complete it with high precision, high quality, and high speed so that the building achieves both beautiful and economic effects.

Lightweight Prefab Steel Building Structure

The light steel structure comprises only round steel, small-angle steel, and thin-walled steel. The light steel structure’s roof load is more delicate, so the members’ cross-section is smaller and thinner. In addition to the lightweight of ordinary steel structure, uniform material, accurate and reliable stress calculation, simple processing and manufacturing, the high degree of industrialization, and convenient transportation, it generally has the advantages of suitable material acquisition, less material consumption, and lighter weight.

The steel consumption of light steel structure is generally 8~15kg/㎡, close to the steel consumption of reinforced concrete under the same conditions. It can save a lot of wood, cement, and other building materials and reduce the ordinary steel structure’s structural weight. 70~80% of the total cost, the total cost is relatively low.

The lightweight prefab steel building structure is a field that has developed rapidly in the past ten years. The United States accounts for more than 50% of non-residential construction investment. This structure has a high degree of industrialization and commercialization, fast construction, high comprehensive benefits, and significant market demand. It has attracted the attention of structural designers. This structure is widely used in warehouses, offices, industrial garages, and sports facilities.

Steel tube concrete structure

A concrete-filled steel tube (CFST) is a construction component made by filling steel tubes with plain concrete. It has the outstanding advantages of high bearing capacity, good seismic performance, steel saving, and simple construction, so it has been widely used in high-rise and super high-rise buildings. Its promotion and development speed is very rapid, and it will become a convenient and main structural form of high-rise and super high-rise buildings in the 21st century.

The characteristics of the structure are:

- The compressive and shear bearing capacity of the concrete-filled steel tube column is high, which is equivalent to more than twice the sum of steel tube and concrete;

- Compared with reinforced concrete columns, the concrete-filled steel tube columns reduce the cross-section by more than 60%, and the outline size is also smaller than that of steel columns, which expands the use space and area of the building;

- The reduction cross-section of column and removal weight is conducive to seismic resistance of the structure, which is equivalent to a decrease of fortification intensity by one level;

- The self-weight of the concrete-filled steel tube column is reduced, which reduces the load on the foundation and correspondingly reduces the cost of the foundation;

- The thin wall of the steel pipe is convenient for material selection, manufacturing, and field welding, which is a high-speed construction structure;

- The concrete in the concrete-filled steel tube column can absorb a large amount of heat energy, and its fire resistance is better than that of the steel column so that it can save more than 50% of the refractory coating than the steel column.

Its good overall performance also overcomes the shortcomings of local instability of ordinary steel columns. Therefore, compared with reinforced concrete columns, it can reduce cross-section design by more than 60%.