In the construction of modern storage facilities, steel structure warehouses have become one of the mainstream building forms due to…

This article will introduce a design case of a 66x75m steel structure warehouse using a portal steel frame structure, which complies with the GB51022-2015 design standard.

The warehouse size is 66m x 75m, divided into three spans: 24m, 18m, and 24m. The eaves height is 6m, and the roof materials include 0.5mm thick corrugated metal sheet, 75mm thick insulation cotton, and 0.4mm interior sheet. The main structure is made of Q355B material, and the secondary system is made of Q235B material.

66X75m Steel Structure Warehouse Design Plan

1. Span of the 66X75m Steel Structure Warehouse :

Considering the special usage requirements (the middle 18m also serves as a traffic walkway), the customer specified the above span requirements. Therefore, the width of 66m is calculated as a span of 24m + 18m + 24m,

Generally speaking, if possible, it is more economical to design the frame into a symmetrical structure, with the spans of each span being basically the same and the middle span slightly larger than the side span.

2. Column distance selection:

The total length of the warehouse is 75m, so the column distance is 7.5m, that is, 10@7.5

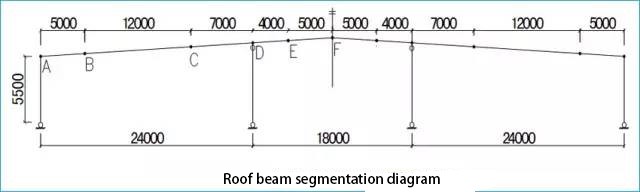

3. Roof beam splicing node settings

Node setup needs to consider the following factors:

The splicing point should be as close to the reverse bending point as possible. Generally, the reverse bending point is located at 1/4~1/6 of the span.

The unit length should not exceed the maximum transportable size and generally should not exceed 12.5 m;

Minimize the number of splices because splicing nodes require end plates and high-strength bolts, which will also increase the project cost;

The splicing nodes should avoid the connection locations of wind columns and roof pipe strut to avoid connection inconvenience;

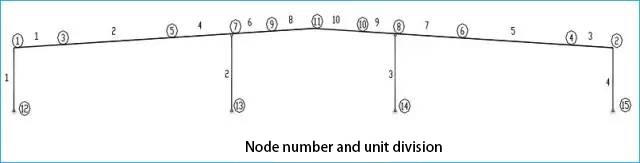

Based on various factors, we segmented the roof beams. Node A is the splicing node between side columns and beams, and node D is the splicing node between center columns and beams. Usually, the roof beams are continuous here.

This is because the bending moment here is significant. We typically do not recommend disconnecting the roof beams at ridge node F because wind-resistant columns and roof ties are usually here. If roof ties are installed, it will cause inconvenience in the connection. In this way, the 66m roof beam is divided into seven sections.

3. Load calculation

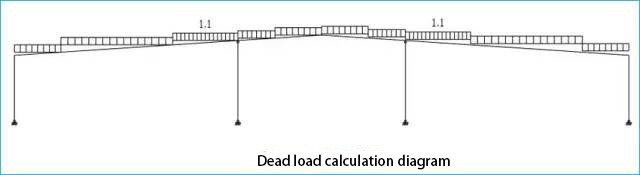

Dead load calculation:

The dead loads acting on the roof beams are:

0.5mm thick profiled steel plate, weight 0.57.851.25= 5.0 Kg/m2

75mm thick thermal insulation cotton (bulk weight 14kg/m3) 7514/1000=1.05Kg/m2 0.4mm thick roof lining board, weight 0.47.85*1.1=3.5Kg/m2

The importance of roof purlins is generally 3-5Kg/m2

The weight of roof supports, tie rods, purlin braces, corner braces, etc., can be 2Kg/m2

The total weight of the above is about 15 kg/m2, and the dead load acting on the frame is 0.15KN/m2*7.5m=1.125KN/m.

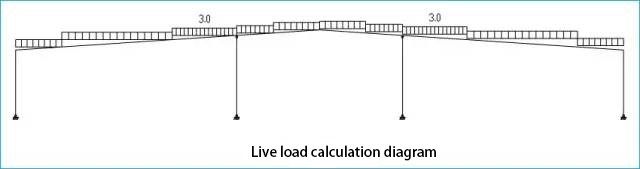

Live load calculation:

Since the load-bearing area of each frame is A=667.5=495m2>60m2, the live load can be taken as 0.3KN/m2. The suspended load on the roof is 0.1 KN/m2. We consider the suspended load in the live load. The live load is 0.4KN/m2, so the live load acting on the frame is 0.4KN/m27.5m=3.0KN/m.

Wind load calculation:

The standard value of wind load is 0.4 KN/m2. The wind load type coefficient of the internal typical span is shown in the figure below.

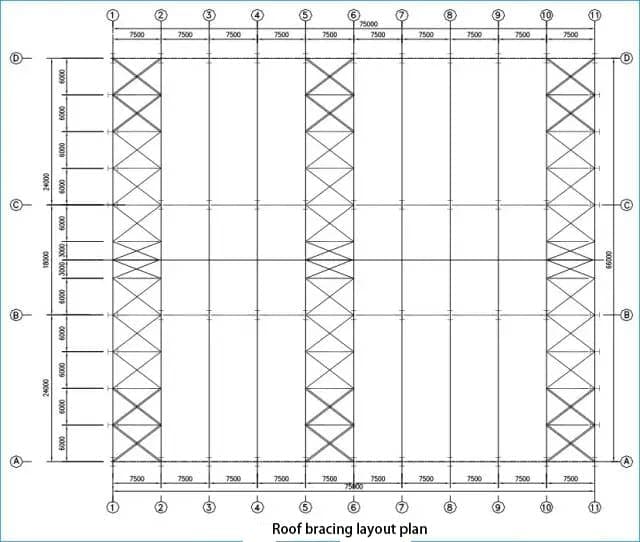

The structural layout of the 66X75m Steel Structure Warehouse

The length of the steel structure warehouse is 75m. According to the portal steel frame specifications, the distance between the supports between the columns should be 30 to 45m when no crane exists. Therefore, installing three inter-column bracings at the end spans, and the more intermediate spans is necessary.

When the width of the warehouse building is more excellent than 60m, the inter-column supports should be appropriately added to the inner column rows. The span of this project is 66m >60m. According to regulations, additional inter-column supports should be added on the B and C axes.

Establish a calculation model.

Since no crane is inside this warehouse, the column feet can be hinged, and the center column can be a swing column. See the figure below for the calculation diagram and unit node division.

Steel structure warehouse design considerations:

Load calculation: When designing a steel structure warehouse, you first need to calculate the loads required for the warehouse, including roof live loads, dead loads, wind loads, and earthquake loads. These loads affect the design and strength of the structure.

Structural design: When designing a steel structure, the stability and safety of the structure must be ensured. This includes the design of beams, columns, and connectors, etc.

Foundation design: The foundation design is based on the internal structure of the warehouse. The foundations of steel columns are usually rigidly connected for facilities with cranes or mezzanines inside. For single-layer warehouses without cranes, the column feet are hinged.

Design standards: Steel structure building design should be calculated according to local design standards, and structural calculations should be performed under the requirements specified in the design standards.

In the design of steel structure warehouses, special attention should be paid to critical points such as structural load calculation, structural design, foundation design, and compliance with local design standards.