In the construction of modern storage facilities, steel structure warehouses have become one of the mainstream building forms due to…

Prefab Steel warehouses are becoming more and more widely used in modern industrial production. Some products produced by factories directly enter the market, but most factories have stocks, which requires specialized stock warehouses. There is not much difference between the steel workshop building and the warehouse building—one used for production workshop, and the other applicants for warehouse inventory. Nowadays, the use of prefab steel warehouse is more and more widespread.

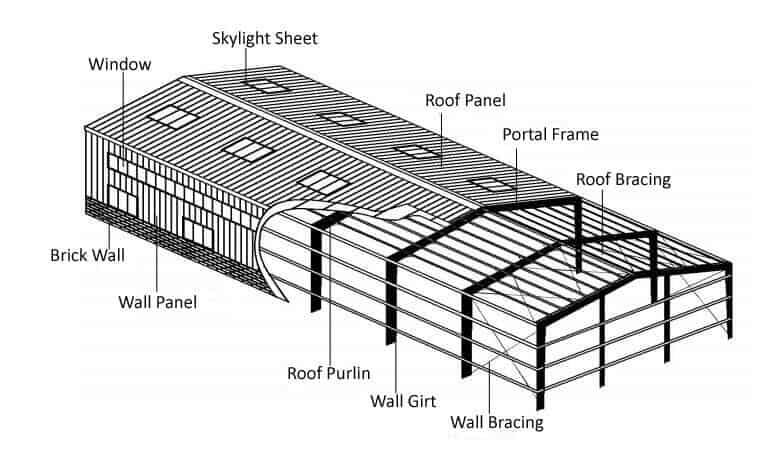

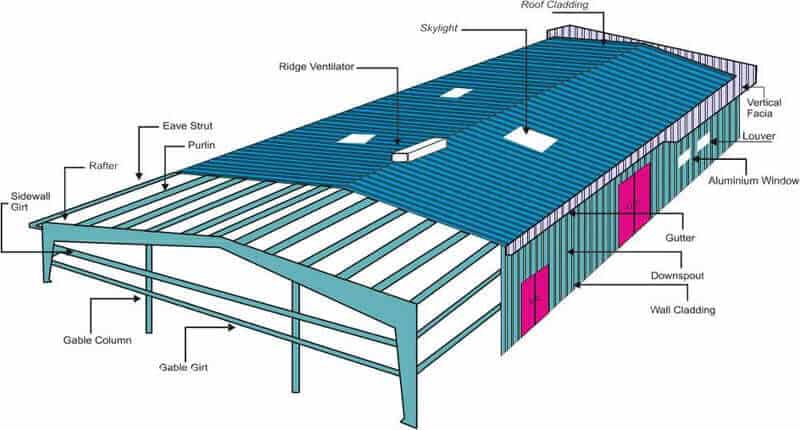

1.Composition of Prefab Steel Warehouse:

1).Main load-bearing framework: Portal frame

2).Purlins, wall girt: C/Z cold-formed steel

3).Wall and Roof Panel: Corrugated single color sheet or sandwich panel

4).Roof and wall insulation core material: polystyrene foam, polyurethane foam, rock wool, etc.

5).Roof and Wall Bracing: Rod steel or L angle steel.

2.The type of structure

Portal steel frame

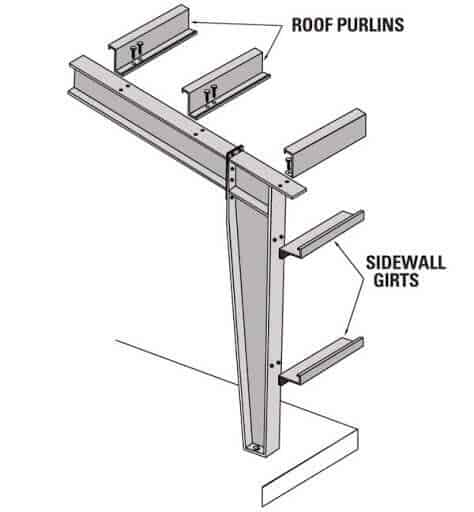

The Portal frame is a traditional structural system. The upper primary frame of the type of structure includes rigid frame beams and columns, bracing, purlins, tie rods, wall girt, etc.

The steel structure portal frame is a branch of the light steel structure.

The characteristics of the structure:

1). Reflect the characteristics of lightweight, speed, and efficiency of the light steel structure. It applies new energy-saving and environmentally friendly building materials.

2). Realize factory processing and production, on-site construction, and assembly. Convenient and fast, save the construction period.

3). The structure is sturdy and durable, the price is reasonable, and the economic benefits are obvious.

4). The size of the column distance is free and flexible. It can meet the construction and use requirements under different climatic and environmental conditions.

The main application range of the steel structure portal frame includes steel structure workshop, metal warehouse building, industrial shed, aircraft hangar, etc.

3.Enclosure structure of Prefab Steel Warehouse:

The wall and roof panel divided into two types: corrugated single color sheet and sandwich panel.

The single color metal sheet is used for buildings without heat preservation and heat insulation requirements.

Sandwich panels mainly apply for the buildings with the requirement of thermal insulation. The core materials of sandwich panels include foam, glass wool, rock wool, and polyurethane.

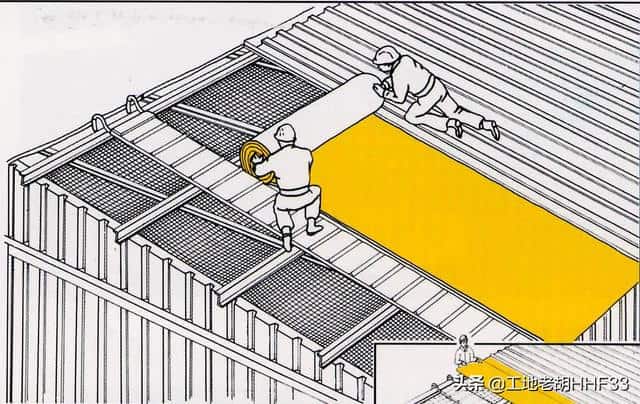

The other is the corrugated single color sheet with glass wool roll, which compounded on site.

The role of roof and wall enclosure structure:

1) Purlins and girt are necessary frameworks, which are combined with metal cladding to form roof and wall.

2) Transmit horizontal force together with the bracing system and stabilize the overall building.

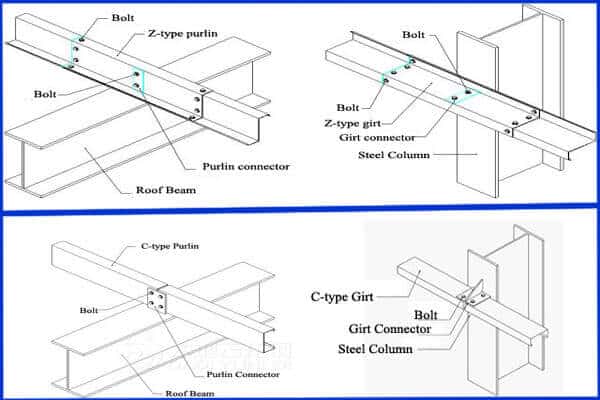

4.Purlin and wall girt

The main types of purlin and wall girt are C-type or Z-type, and the size of the section shall determine after the force calculation.

Compared with the Z-shaped cross-section, the mechanical properties of the C type are quite different. The Z-type purlin erected in overlapped, so it is a continuous beam.

And the maximum distance between the purlin and the wall girt shall not exceed 1.5 meters.

5.The process of prefab steel warehouse

1). Design:

Design is the source of all procedures. Intelligent design not only saves costs but also makes construction smoother.

2). Production:

Production is the components of steel structure warehouse fabricate according to the designed plan. It included the following steps.

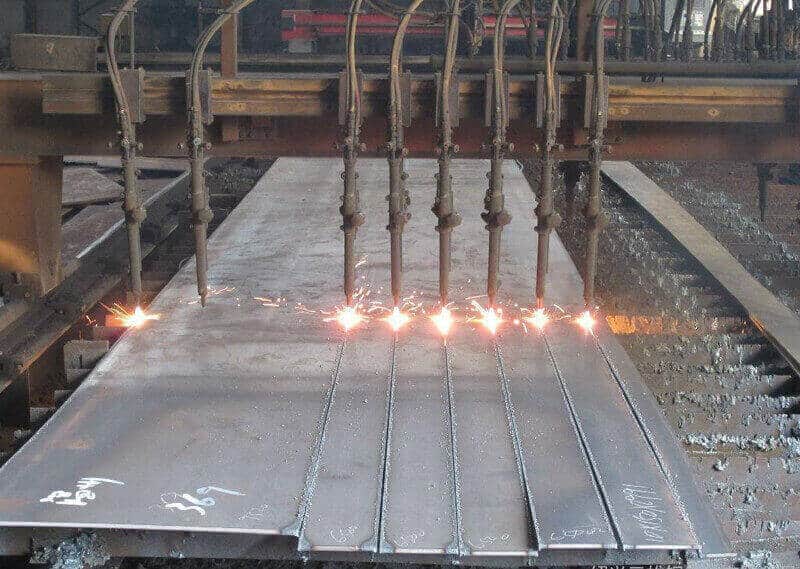

(1) Cutting.

The process is for the formal processing of steel components. The quality of the cutting has a direct impact on the next process. If the cutting is not correct, the material may become scrap iron. So it is essential to strengthening the quality control of the process.

(2) Welding.

It is one of the processes most prone to quality problems. So the sufficient welding strength must apply to ensure the durability of the components.

(3) Painting.

This process has a significant impact on the service life of steel structure buildings. A good coating can prevent steel structure from rusting and corrosion for a long time, increasing the service life of the steel structure warehouse.

3). On-site installation:

This process occupies an essential position in the quality of the project and has a more significant impact on the entire steel structure warehouse.

6.Advantages of Prefab Steel Warehouse:

1). Lightweight and high strength.

The prefab steel warehouse is only about 1/2 weight of the reinforced concrete building, which meets the needs of the ample space. There is no column barrier inside, clearspan, and vast internal space.

2).Environmental friendly.

Steel structure materials can recycle, and pollution reduced during construction and dismantling.

3). Fast Installation:

The construction time of the steel structure warehouse building is short. As components are all prefabricated in the factory, and the site only needs to be assembled. It significantly shortens the construction period.

4. Performance:

The prefab steel warehouse is durable and easy to repair, and simple maintenance.

5. Appearance:

The steel structure workshop is beautiful and practical, with simple and smooth lines. The color wall panels are available in a variety of colors, and the walls can also apply for other materials. So it is more flexible.

6. Lower Cost:

The steel structure warehouse has a reasonable cost. Lightweight components can reduce the value of the foundation.