The Introduction of Steel Workshop Building

Steel workshop Building is a steel structure buildings that house production equipment. They are widely used in industrial production and essential to industrial buildings. According to their functions, they can be divided into production workshops, auxiliary production workshops, etc. Compared with traditional concrete buildings, steel structure workshops use steel plates or section steel instead of reinforced concrete. They have the advantages of large spans and fast construction speeds and have gradually replaced traditional structures.

The components of Steel Workshop Building

The main components of a steel workshop building usually include steel columns, crane beams, steel beams, purlins, supports, walls, and roofs. The interconnected components are assembled by welding or bolting to bear external loads. Steel structure workshops can be designed according to the owner’s needs, and the layout is more flexible than traditional concrete structures.

Steel structure components can be manufactured in the factory and transported to the construction site for installation. Due to the high degree of prefabrication of these components, the construction period is significantly shortened, and they can be put into use more quickly, reducing the overall construction cost and construction period.

Main Structure

1. Embedded components (stable the main structure)

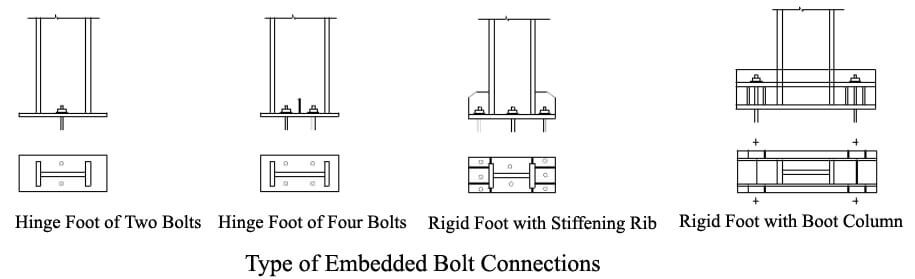

It is divided into an embedded bolt connection and a plug-in cup-shaped mouth connection. The common connection method of ordinary steel structure workshop is mainly embedded bolt connection. Including hinge connection and rigid connection.

The shape of the embedded bolt is usually “L” and is made of steel rod. The diameter and length are determined according to the design requirements. Usually φ24~φ64mm. The tightening force of a single bolt can reach 300KN.

2. Steel column and beam

The column and roof beams of the steel workshop building are usually H-shaped steel made of section steel and steel plate. Columns and steel beams welded with steel plates need to be corrected after assembly and welding to prevent the H-section steel from deforming due to welding deformation. Steel columns and beams are usually connected by welds or bolts, which are the workshop’s main load-bearing structure.

Secondary Structure

1. Purlin and wall girt

It uses C or Z-shaped steel, and the section size is determined after force calculation. The distance between the purlin and the wall girt generally does not exceed 1.5 meters.

2. Bracing

There are roof bracing and column cross bracing. It is usually made of round steel, angle steel, or square tube. The bracing system is used to stabilize the steel frame.

3. Sag rod

The sag rod is connected between the purlins to adjust and control the two adjacent purlins’ stability. Generally, the sag rod is made of round steel with a diameter of 12 or 14 mm.

Roof and wall panels

Roof and wall panels are divided into two types: corrugated single sheet and sandwich panels. The single color sheet is usually used for buildings without thermal insulation requirements, relying on purlins or wall girt to form a roof and wall enclosure structure.

Sandwich panels are mainly used in buildings that require heat preservation and heat insulation. The sandwich panel’s core materials mainly include polyphenylene, polyurethane foam, rock wool, and glass wool.

Load-bearing system of Steel Workshop Building

1. Horizontal frame

The horizontal frame comprises steel columns and supporting roof trusses or roof beams. It is the primary load-bearing system of the steel structure factory. It bears the wind, snow, and vertical and horizontal loads of the crane from the outside.

The bearing coefficient of the whole structure is relatively high. The design of the horizontal frame of the steel structure factory should be reasonable and effective, and the installation of the entire horizontal frame should be done well.

2. Longitudinal plane frame

The longitudinal plane frame of the steel workshop building is composed of columns, crane beams, and inter-column bracing. Its function is to ensure the longitudinal invariance and rigidity of the steel structure workshop skeleton, bear the longitudinal horizontal load, and transfer it to the foundation.

3. Roof structure

The roof structure is a structural system that bears the roof load, including roof beams, purlins, etc. The steel workshop building’s roof system needs to determine which system to choose according to the size of the area. Selecting a suitable roof structure can bear the roof load and will not cause the roof to leak easily.

4. Bracing system

The bracing system includes the roof bracing, the bracing between columns, and other bracing. On the one hand, it forms the longitudinal structure of the steel structure workshop building with columns, crane beams, etc., and bears horizontal effects such as longitudinal wind load and crane braking force.

On the other hand, it connects the primary load-bearing system from independent plane structures into a spatial overall structure. Then, it ensures the longitudinal stiffness, integrity, and stability required for the steel structure workshop.

The roof structure and bracing system are vital in supporting the entire structure. A good job in the frame structure of each system of the steel structure workshop can effectively improve its stability.

5. Wall frame

The wall frame bears the deadweight and wind load of the wall and is generally composed of wall frame beams and columns. When the wall is a self-supporting brick wall, it only bears the wind load on the wall surface, and the entire wall weight is transmitted to the bottom of the reinforced concrete beams placed on the adjacent column foundation or a dedicated wall foundation.

Only wall frame beams are provided for side walls with smaller longitudinal column spacing; for roofs and side walls with larger longitudinal column spacing, wall frame columns are required to support the wall frame beams. The lower end of the wall frame column is provided with a foundation, and the upper back is connected to the node of the horizontal bracing of the upper or lower chord of the roof.

The Advantage of Steel Workshop Building

Advantages of steel structure workshop

1. Easy to assemble

The steel components arriving at the construction site are all prefabricated. During the construction process, the installation work needs to layout each structure and erect it according to the installation drawing.

The installation sequence of the steel workshop building is:

First, install the steel columns and column cross-bracing and install roof beams and roof horizontal bracing. Finally, installs the purlins and enclosure structure.

2. Reasonable cost:

The steel structure workshop building is light in weight, reducing the basic cost, and the construction speed is fast. It can be completed and put into production as soon as possible. The overall economic benefits are much better than that of the concrete structure

3. Simple construction, short construction period.

The production and installation of steel structure usually involve processing all required components in the factory and then transporting to the construction site to assemble. So the construction period is greatly shortened. A 4000 square meter building can be basically installed in only 40 days.

4. Energy-saving and environmentally friendly

The corrugated color steel sheet and sandwich panels used in the prefab steel structure workshop are all energy-saving materials. The steel structure also adopts dry construction during the construction process to avoid dust and environmental pollution caused by concrete construction.

Steel workshop building components

Steel workshop buildings have become a structural system with perfect design, manufacturing, and construction standards. The steel structure workshop is generally a space system. It comprises the roof structure, steel columns, crane beams, brake beams, bracing, and wall girts. The components of Steel workshop buildings The horizontal frame of Steel Workshop Buildings It consists of columns, roof trusses or beams, and bracing connected with the horizontal frame. It is the primary load-bearing system of single-story steel structure workshops. It bears the structure's weight, wind, snow loads, and vertical and lateral loads of cranes and transmits these loads to the foundation…