A steel portal frame structure is a type of low-rise building composed of steel columns and rafters joined by rigid…

The 2022 Beijing Winter Olympics will be held perfectly and bring a visual feast to the world. While enjoying the dinner of the Winter Olympics, the competition venues with different shapes also left a deep impression on everyone. What are the secrets of the heavy steel structures?

Beijing Winter Olympics Accelerates Green Transformation of China’s Steel Industry

To fully reflect the concept of green and low-carbon hosting of the Beijing Winter Olympics, the construction of the Beijing Winter Olympics venues includes auxiliary facilities. The primary materials used are high-quality steel with high strength, toughness, and high corrosion resistance. The total amount of steel used in constructing the Winter Olympics venues and main supporting projects exceeded one million tons. Many large iron and steel enterprises in China and some enterprises with particularly competitive advantages have participated in guaranteeing the supply of steel for the Olympics. By participating in the guarantee of the collection of steel for the Winter Olympics, the adjustment and upgrading of the structure of steel varieties have been promoted. For example, the heavy steel structures have replaced the original reinforced concrete, and the use of higher-strength steel has brought about a reduction in steel production. Doubling the strength of steel means that its dosage will be reduced by half, and if its corrosion resistance is doubled, its life will be doubled. It can be seen how significant this is for energy conservation and environmental protection.

Due to the climatic requirements of the Winter Olympics, the steel plate must have strong “atmospheric corrosion resistance”. It is reported that the weather resistance of the steel used in the Winter Olympics is eight times that of ordinary steel. A total of 7 high-quality steel were used in the Winter Olympics, 5 of which were new types of steel. Let’s experience the new concepts brought by China’s brilliant steel and green steel to the Winter Olympics.

Those heavy steel structures in the Beijing Olympic Games

The core key project of the Beijing Winter Olympics – the National Snowmobile Sled Center (“Snow Dragon”) project mainly includes the main track, training track and auxiliary buildings, etc. It is the most challenging design and construction project for the 2022 Winter Olympics. It is because of the most complex facility. What’s more difficult is that “Xueyoulong” is in direct contact with the air, and the surface needs to be anti-replicating ice, which requires that the steel plate on which “Xueyoulong” is laid must have strong “atmospheric corrosion resistance.” In response to such a demand, experts applied to weather steel to the snowmobile track for the first time. Weathering steel is a steel that is resistant to atmospheric corrosion. It is low-alloy steel between ordinary steel and stainless steel. Its atmospheric corrosion resistance is eight times that of common steel. According to reports, “Xueyoulong” used 1,200 tons of weathering steel for race tracks, and the National Alpine Ski Center also used more than 6,000 tons of weathering steel for construction for the first time.

Heavy steel structures in Olympic venues

Beijing Winter Olympic Village is about 2 kilometers away from the “Bird’s Nest,” “Water Cube,” and the National Gymnasium, and about 4 kilometers away from the “Ice Ribbon” of the National Speed Skating Stadium. Athletes take the shuttle bus from the Winter Olympic Village to the competition venue in two or three minutes. ; It is only more than 20 kilometers away from the competition venue of the Shougang Ski Jumping Project, which is the farthest, and it takes about half an hour by car. Beijing Winter Olympic Village adheres to long-term use design and construction concepts. After the game, it will be used as public rental housing for talents in Beijing, and it will be allocated to skills that are in line with the strategic positioning of the capital city.

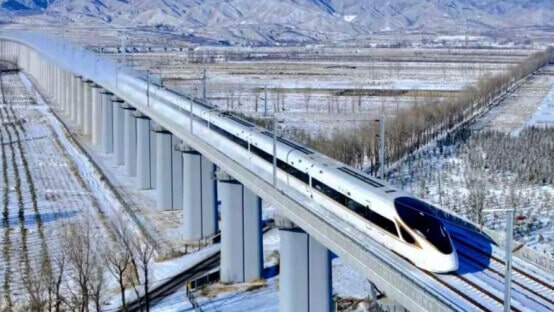

The Beijing-Zhangjiakou high-speed railway is a crucial transportation support facility for the Beijing 2022 Winter Olympics. It is the first intelligent high-speed railway in China that adopts the self-developed Beidou satellite navigation system and has a design speed of 350 km/h. It is also the first in the world. The high-speed railway with a maximum design speed of 350 km/h in high cold and sandstorms.

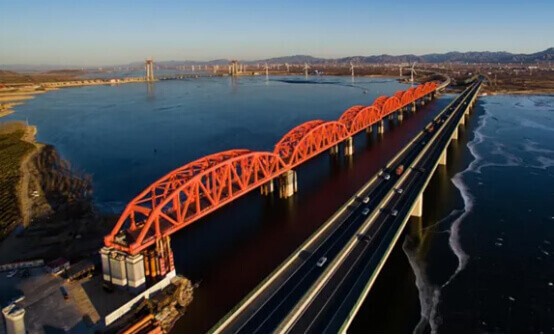

The Guanting Reservoir Bridge, like a bright pearl, is embedded between the Beijing-Zhangjiakou high-speed railway. The bridge’s design reflects the modern railway construction concept of “light weight, large span, and environmental protection.” The steel has high-performance indicators such as high strength, high toughness, earthquake resistance (low yield-to-strength ratio), easy welding, and weathering resistance.

Green is one of the concepts of the Beijing Winter Olympics. During the event, all venues of the Beijing Winter Olympics will be supplied with green electricity, which is the first time in the history of the Olympic Games. Fengning Pumped Storage Power Station, the world’s largest pumped storage power station with the largest installed capacity, is a crucial project for the Beijing Winter Olympics venues to achieve a 100% green power supply and is also a critical project to help achieve the “dual carbon” goal, promote energy transformation and green development, Another essential achievement in building a new power system.

The western section of Beijing Metro Line 11, the Winter Olympics branch line, is a rail transit line serving the Beijing 2022 Winter Olympics and a smart rail transit demonstration line in Beijing. The opening of this new line enables all venues in the Beijing Division of the Beijing Winter Olympics to be reached by subway. In addition, Nangang provided 1,244 tons of steel for subway bogies for Beijing Metro Line 11, Line 12, and Line 3 extension lines.

The Shougang Ski Jump is the only snow sports venue located in the urban area of the Beijing Winter Olympics, and it is also the world’s first permanent ski jump venue. It relies on industrial relics for construction, and its shape design incorporates the “flying sky” element in Dunhuang murals, a well-known world cultural heritage in China. Its meaning is similar to the English word Big Air of the ski jumping platform project, both of which have the sense of leaping into the air and flying. The curve of the flying streamer is very consistent with the curve of the center of the Shougang ski jumping platform. The shape of the building is very beautiful and smooth. Different parts of the Shougang ski jump platform have different special requirements for the performance of steel. For example, the main support structure of the big jump platform must be able to resist strong winds of magnitude 12 and earthquakes of magnitude 8. In addition, the steel structure track of the big jump platform needs to solve the world problem of severe corrosion by repeated use of the snow-melting agents. Because of the requirement of permanent preservation and use, the structure is required to be safer, the shape is more beautiful, and the maintenance is more accessible. We have used seven high-performance steel, five of which are used for the first time in China.

Advantages of high-quality heavy steel structures

In addition, another advantage of using high-quality steel is that it has changed the practice that steel used in construction needs to be regularly painted to prevent corrosion, thus significantly reducing the environmental pollution caused by paint.

One of the Beijing Winter Olympics highlights is the “green Olympics.” To reflect the concept of environmental protection, the national speed skating stadium, known as the “Ice Ribbon,” has become the first-speed skating stadium in the Winter Olympics to use carbon dioxide as a refrigerant. The total length of the stainless steel refrigeration pipes is 120 kilometers, which puts forward very high requirements on the processing accuracy of the steel.

The ice surface of the National Speed Skating Stadium has the lowest ice surface temperature among all the Winter Olympic venues. According to the requirements of the competition, the temperature difference of the entire ice surface should be controlled at 0.5 degrees Celsius. Carbon dioxide is gaseous at standard temperature and pressure. Still, after applying specific high pressure, Carbon dioxide will become fluid in a critical state. These fluids are transported to the refrigeration pipes under the ice surface through stainless steel refrigeration pipes to achieve the purpose of cooling and refrigeration. If the ice surface temperature is uneven, some places are complex, and some areas are soft, which will affect the players’ performance. Therefore, our stainless steel pipes are used as fluid conveying pipes, and the dimensional accuracy of the products must be ensured.

Below the ice surface of the “ice ribbon,” layers are laid like “thousand-layer cakes.” Moreover, the welding between the 120 kilometers of stainless steel refrigeration pipes in the entire ice rink is very critical, especially for the steel pipes of different diameters and lengths, which need to be bent into different arcs, so the requirements for the accuracy of the steel pipe dimensions are also more stringent.

In the steel pipe straightening process, we used a high-precision straightening machine for the first time, and it was repeated twice. As a result, the connection between them can be highly matched to ensure the flow and flow rate of liquid carbon dioxide during the flow process and the fastest ice temperature.