In the construction of modern storage facilities, steel structure warehouses have become one of the mainstream building forms due to…

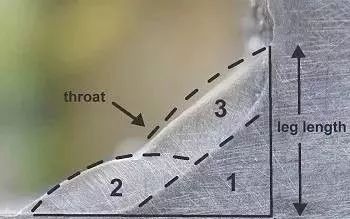

Fillet welding is when two welding surfaces are perpendicular to each other. The welding fillet is the length of the isosceles right-angled side, the welding throat is the height of the hypotenuse of the isosceles right-angled triangle, and the fillet weld is the right triangular section.

Fillet welds are the most common form of welding in the steel structure welding process. Therefore, many welders will encounter different styles of fillet welds, and they also have different standards. So, how does the fillet weld well? What about getting fillet welds that meet your requirements? In this article, we will introduce it in detail.

Introduction to fillet welding

1. Selection of base material

Below, we will give a brief introduction using a test plate with a base material of Q355B and a size of 200x125x12mm as an example.

2. Selection of welding materials

Welding material: E5015 (J507) welding rod is selected, the drying temperature is 350~400°C, and the heat preservation is 2 hours. The welding wire complies with the national ER50-6 (American standard ER70S-6).

3. Cleaning before welding

The 15~20mm on both sides of the weld must be cleaned for fillet welds. Use grinding wheel grinding or chemical treatment to remove oxide film, rust, oil, and water on the surface of the plate.

4. Assembly points

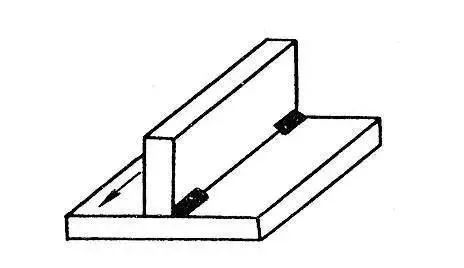

Generally, fillet welding requires the weld gap to be as small as possible. The spot-fixing is usually done on the back of the board, and the spot-fixing length is about 10mm. Generally, just two to three points can be fixed, as shown in the picture:

Fillet welding operation

Bottom welding

Welding rod angle and rod transport method

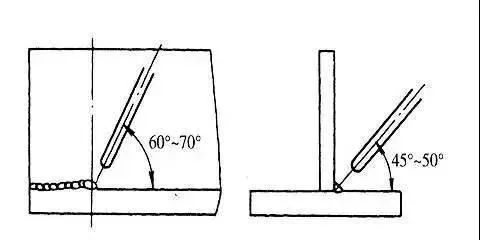

The electrode angle for root fillet welding is shown in the figure: Use the proper welding method, strike the arc on the left side of the test plate, and perform short arc welding.

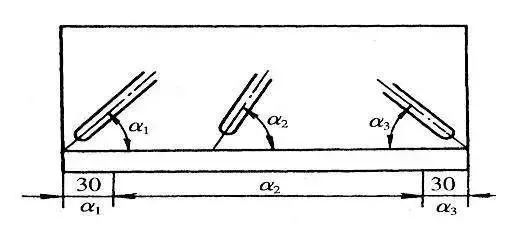

Use a straight line to weld to the right, align the arc at the top corner of the root, and suppress the arc to ensure that the top corner and both sides of the plate are fused. During bottom welding, the swing method adopts a straight line to move the bar and weld quickly without swinging to achieve the required penetration.

At the beginning and end of the weld, the magnetic blow is prone to occur, affecting the weld’s quality. At this time, the angle of the welding rod must be adjusted appropriately, and the arc is generally directed toward the molten pool to control magnetic blow.

Weld bead joint

The joint strikes the arc 10mm in front of the arc crater. When the arc is stretched and quickly moves to the arc crater, the arc crater is filled along the shape of the arc crater and then welded.

Cover welding

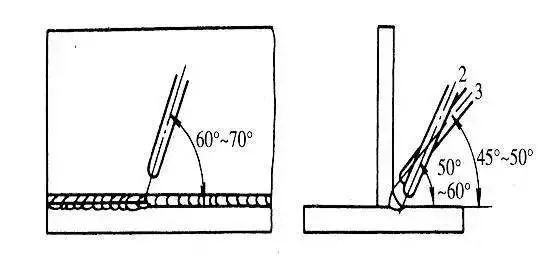

Before cover welding, remove slag and spatter from the root pass to prevent slag inclusion defects.

The cover surface has two welding passes; the lower pass is welded first, and the upper pass is welded. When soldering the lower weld bead, the arc should be aligned with the lower edge of the root weld bead, and the rod should be moved in a straight line, with the angle of the welding rod being more significant than 45°.

When welding the upper weld bead, the arc should be aligned with the upper edge of the root weld bead, and the linearly moved rod can also swing laterally. , the angle of the welding rod should be <45°

Convex fillet welding

Concave fillet welding

When welding the upper weld bead, the arc should be aligned with the upper edge of the root weld bead, and the linearly moved rod can also swing laterally; the angle of the welding rod should be <45°

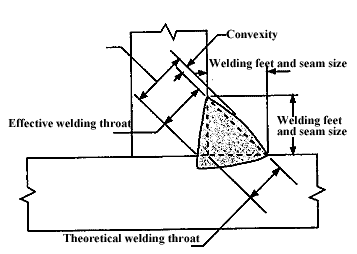

Theoretical Weld Throat: The vertical distance from the base of the joint to the hypotenuse in the most giant inscribed right triangle drawn within the fillet weld profile.

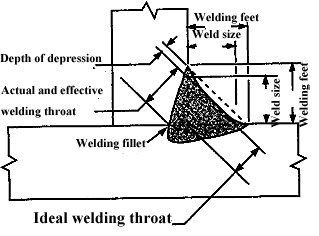

Effective weld throat: The minimum distance from the fillet weld surface to the weld root minus the raised portion.

Actual weld throat: The shortest distance between the fillet weld surface and the weld root. Since there is no raised part for concave fillet welds, the effective weld throat equals the actual weld throat.

Weld feet size: The distance from the root of the joint to the toe of the fillet weld.

Weld Toe: The intersection of the weld surface and the base metal.

When determining the size of the fillet weld, you must first know whether the weld is convex or concave. The convex shape refers to the slight convexity caused by the bulge on the surface of the weld, which is related to the height of the bulge. The raised height of the fillet weld is the same as the reinforcement height of the groove weld.

If a weld is dented, it means that the surface of the weld is dished.

For these two shapes, the weld size of a fillet weld with equal leg heights is expressed as “the straight side of the largest isosceles right triangle obtained in the fillet weld profile (two legs of equal length).”

Therefore, the weld feet equal the weld size for a convex fillet weld, but the weld size is slightly smaller than its leg length for a concave weld.