In the construction of modern storage facilities, steel structure warehouses have become one of the mainstream building forms due to…

Steel building installation is one of the essential links of steel structure buildings, and the quality of installation is directly related to the safety and durability of the building. Therefore, a series of precautions must be taken while installing steel structures. Below, we will introduce the precautions for steel structure installation in detail.

Steel building installation process:

Steel structure foundation construction

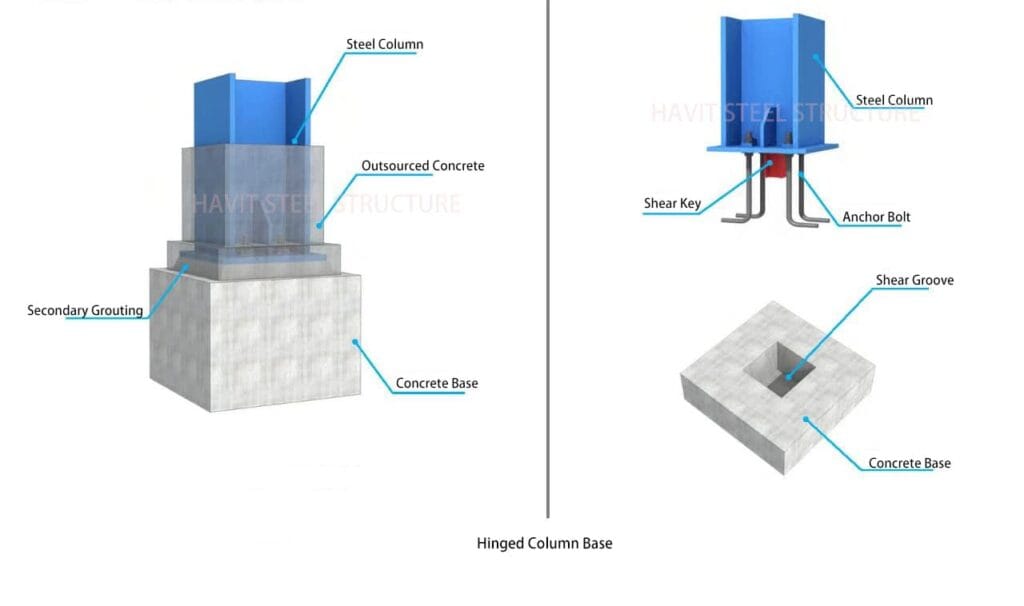

The construction of the foundation of the steel structure mainly involves pre-buried anchor bolts. The steel column is connected to the foundation through the anchor bolts. The construction quality directly affects the safety and stability of the steel structure. Therefore, the construction of the anchor bolts is crucial. If the size of the anchor bolts is inaccurate, the steel structure will not be able to be installed. Therefore, in the process of anchor bolt construction, extremely high precision is required, and no error is allowed.

Column foot anchor construction process:

1. Foundation layout and positioning

Steel structure buildings mostly use independent foundations. During the construction process, the site must be leveled first, then the layout must be measured according to the design drawings, the foundation axis must be determined, and the center position of the anchor bolts must be marked.

2. Tie the steel bars

After marking the center position of the anchor bolts, the foundation is excavated, and then the steel bars are arranged in the foundation pit. When placing the steel bars, the long steel bars should be placed below, and the short steel bars should be placed above, and they should be spread out according to the spacing. First, fix a few points for positioning, then cross-tie them point by point. Keep the hook facing up and not leaning to one side when tying.

3. Anchor bolts

Use the template to fix the anchor bolts to ensure their position is not tilted. Then, weld the anchor bolts to the foundation steel mesh to improve their strength and stability.

4. Foundation pouring

After fixing the anchor bolts, start foundation pouring. After pouring, use a vibrator to fully vibrate the concrete to prevent the formation of voids around the anchor bolts that affect the anchoring performance. After the construction is completed, re-measure the anchor bolt position and elevation. If there are any size problems, adjust them in time.

Steel Building Installation for Primary Structure

1. Steel column installation

After the foundation construction is completed, start installing the steel column. First, a crane or tower crane is used to lift the steel column and drop it into the pre-buried anchor bolt by slow rotation and vertical drop. Temporarily fix the steel column first, and then use a level, plumb bob, or laser line projection to adjust the verticality of the steel column to ensure that it is tightly connected to the foundation.

2. Roof beam installation

The roof beam is connected to the top of the column and is the main structure that carries the roof purlins and panels. When installing the steel beam, first lift it to the designed height. Then, the construction workers receive it on the temporary platform, guide it to align with the connection point, and fix it with high-strength bolts. Large-span steel beams are usually transported in sections and connected with on-site bolts.

3. Installation of crane beams

The crane beam is a load-bearing structure used to support the crane in the steel structure workshop. When lifting the crane, it should be lifted slowly and kept stable. The construction workers will receive it on the high-altitude platform and guide the crane beam to connect with the bracket. When installing the crane, the horizontality should be maintained. After the installation, it should be measured with a level meter, and the error should not exceed 2mm. At the same time, the elevation should also be checked, and the elevation error should not exceed 3mm.

4. Installation of bracing system and tie beams

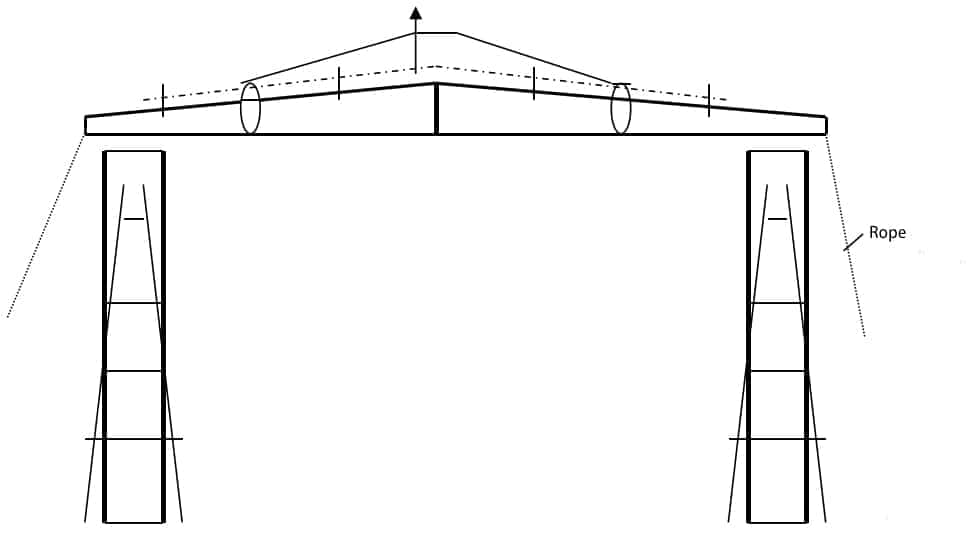

Steel structure bracings include inter-column bracing, roof bracing, and flange bracing. Steel structure bracing and tie beams enhance structural stability and resist wind loads and earthquakes.

Usually, after the steel columns and crane beams are installed, inter-column bracing and tie beams need to be installed to provide temporary support.

Tie beam installation: First, hoist the tie beam to the designated position and use bolts to connect the two ends to connect it with the steel column.

The column bracing and the roof horizontal bracing are installed according to the requirements of the design drawings.

5. Purlin installation

Purlin supports the roof and wall panels and transfer the load to the main steel frame.

The purlin is connected to the steel column and steel beam bolts through the purlin support plate. During the production process, the purlin will be marked with numbers, and the construction personnel will install it at the designated position according to the number.

6. Accessory installation

After the steel structure is installed, start installing the accessories. Accessories include roof panels, wall panels, skylights, insulation cotton, edges, flashing, gutters, downpipes, and doors and windows. These accessories make the steel structure building more beautiful and provide insulation and waterproofing.

The accessories must be waterproofed during installation to eliminate the hidden dangers of leakage.

7. Re-inspection, adjustment, weld reinforcement, and anti-corrosion repainting

After the steel structure is installed, it is necessary to re-inspect and re-adjust the structural dimensions and node connection quality. Parts broken due to welding or cutting during the installation process need to be re-polished and re-painted with anti-rust paint. To improve the building’s fire resistance, fire-retardant paint must also be sprayed according to the design specifications.

Attention Issues For Steel Building Installation

1. Strictly control the quality of materials.

The quality of materials used when installing steel buildings is essential and must be strictly controlled. Check whether the variety, model, specification, etc., meet the design requirements, and randomly sample the materials for retesting.

They can be used only after the retest is qualified. You can choose matching welding rods, welding wires, and flux according to the steel grade, but all must have certificates.

2. Strictly control the quality of personnel.

When installing steel structures, in addition to paying attention to the quality of materials, you must also pay attention to the quality of the installers.

They must be equipped with technical teacher qualifications. Welding, rivets, and other connections are generally used for steel building installation.

Particular types of work, such as welders and crane operators, must be strictly tested to ensure the operating system’s safety. At the same time, construction personnel’s certificates must be tested to see whether the issuing unit issues them and whether their service life has expired.

3. Pay attention to the connection of steel structures

During the installation of steel building, you must also pay attention to the connection. The components or parts used are all made of steel.

Attention should be paid to the connection quality during installation because if this aspect is not well controlled, it will directly affect the safety of the overall economic structure. It is essential to know the standard connection method selection and connection method, and its reasonable design is a critical part of the steel building installation.

4. Positioning measurement

According to the steel structure installation project planning materials, the horizontal elevation of the root, axis, and column distance should be re-measured.

The cross lines of the vertical and horizontal axes displayed on the top surface of the pipeline are used as the positioning reference for the equipment’s main column.